100% Original Best Sale 4 6 8 colour Stack Flexographic Printing Press for non woven Plastic Bag

100% Original Best Sale 4 6 8 colour Stack Flexographic Printing Press for non woven Plastic Bag

In the past few years, our organization absorbed and digested state-of-the-art technologies equally at home and abroad. Meanwhile, our enterprise staffs a team of experts devoted towards the growth of 100% Original Best Sale 4 6 8 colour Stack Flexographic Printing Press for non woven Plastic Bag, Adhering on the small business philosophy of ‘customer 1st, forge ahead’, we sincerely welcome clientele from at your house and overseas to cooperate with us.

In the past few years, our organization absorbed and digested state-of-the-art technologies equally at home and abroad. Meanwhile, our enterprise staffs a team of experts devoted towards the growth of Flexo Printing Equipment and Flexo Printing Machines, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.

technical specifications

| Model | CH4-600B-NW | CH4-800B-NW | CH4-1000B-NW | CH4-1200B-NW |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High-quality printing: Stacked flexographic presses are capable of producing high-quality prints that are sharp and vibrant. They can print on a variety of surfaces, including paper, film, and foil.

2. Speed: These presses are designed for high-speed printing, with some models capable of printing up to 120m/min. This ensures that large orders can be completed quickly, thereby increasing productivity.

3. Precision: Stacked flexographic presses can print with high precision, producing repeatable images that are perfect for brand logos and other intricate designs.

4. Integration: These presses can be integrated into existing workflows, reducing downtime and making the printing process more streamlined.

5. Easy maintenance: Stacked flexographic presses require minimal maintenance, making them easy to use and cost-effective in the long run.

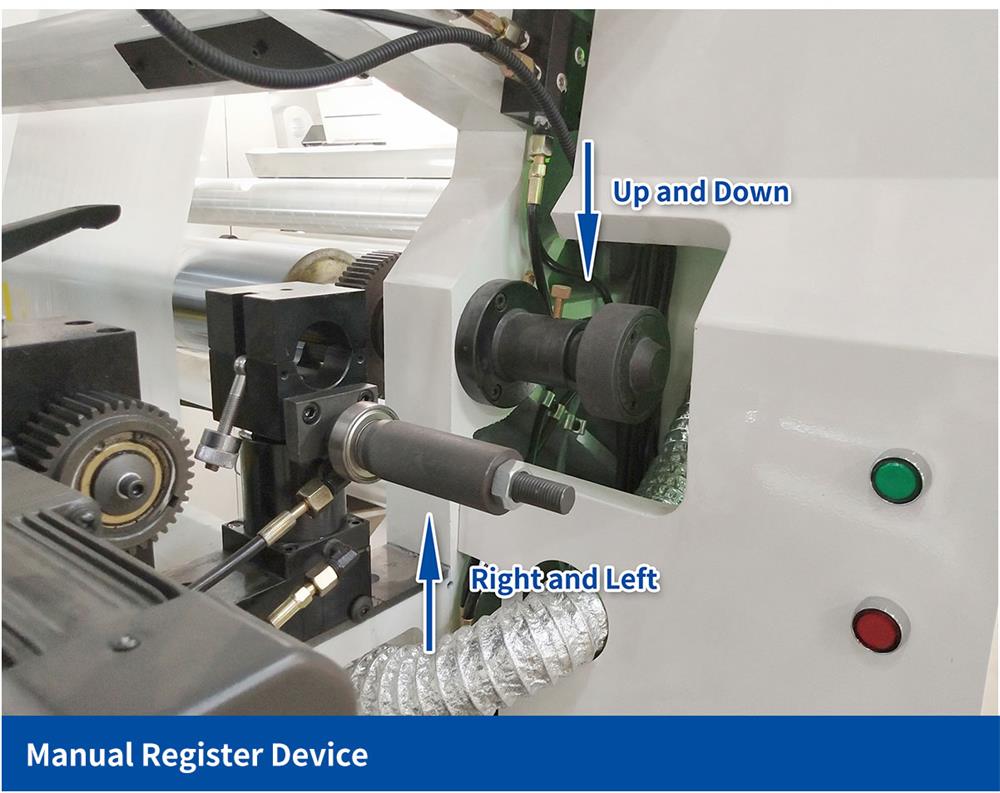

Details Dispaly

sample

In the past few years, our organization absorbed and digested state-of-the-art technologies equally at home and abroad. Meanwhile, our enterprise staffs a team of experts devoted towards the growth of 100% Original Best Sale 4 6 8 colour Stack Flexographic Printing Press for non woven Plastic Bag, Adhering on the small business philosophy of ‘customer 1st, forge ahead’, we sincerely welcome clientele from at your house and overseas to cooperate with us.

100% Original Flexo Printing Equipment and Flexo Printing Machines, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of “human-oriented and faithful service”, with an aim to gain global recognition and sustainable development.