18 Years Factory 2 4 6 8 Color Flexographic Carton Box Plastic Paper Bag Flexo Printing Machinery Roll Flexo Paper Bag Printing Machine

18 Years Factory 2 4 6 8 Color Flexographic Carton Box Plastic Paper Bag Flexo Printing Machinery Roll Flexo Paper Bag Printing Machine

To frequently enhance the management process by virtue of your rule of “sincerely, good religion and good quality are the base of company development”, we greatly absorb the essence of associated solutions internationally, and regularly produce new goods to meet the needs of shoppers for 18 Years Factory 2 4 6 8 Color Flexographic Carton Box Plastic Paper Bag Flexo Printing Machinery Roll Flexo Paper Bag Printing Machine, With a wide range, good quality, fair rates and great services, we are going to be your ideal small business partner. We welcome new and outdated prospects from all walks of lifestyle to get in touch with us for future company associations and achieving mutual accomplishment!

To frequently enhance the management process by virtue of your rule of “sincerely, good religion and good quality are the base of company development”, we greatly absorb the essence of associated solutions internationally, and regularly produce new goods to meet the needs of shoppers for Flexographic Printers and ci Flexographic Printer Machine, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the have to have of customers to meet the requirement of customers.

Technical Specifications

| Model | CHCI4-600J-Z | CHCI4-800J-Z | CHCI4-1000J-Z | CHCI4-1200J-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High precision printing: Paper cup flexo printing machine can produce high-quality prints with a high level of precision.

3. Low maintenance cost: The machine is designed to require low maintenance. It has an easy-to-maintain structure.

5. Versatile: The machine is versatile and can print on various types of materials to produce different types of paper cups.

6. Automatic registration control: The machine has an automatic registration control system, which ensures accurate printing on the paper cups.

7. Cost-effective: The Paper cup flexo printing machine is a cost-effective production tool, and it can help increase the profitability of paper cup production.

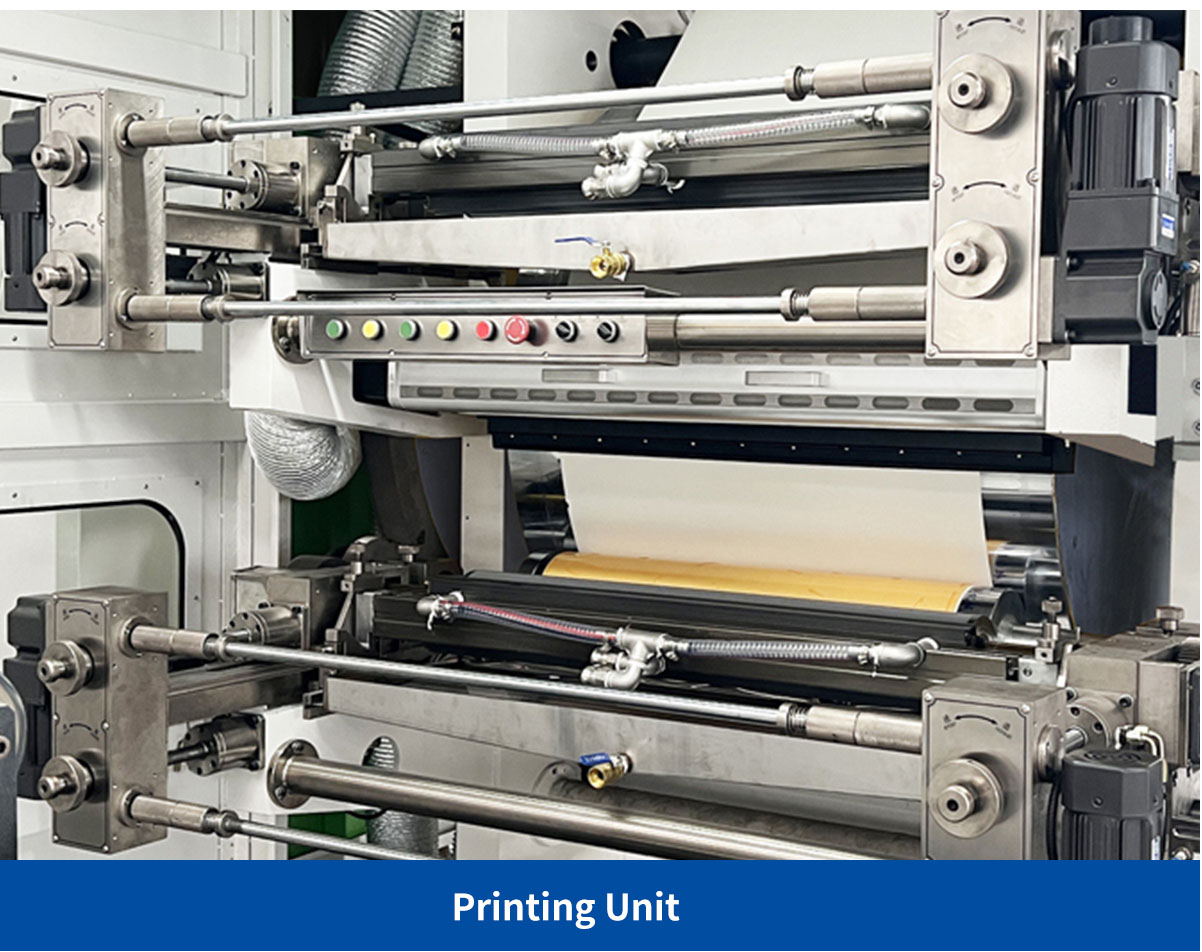

Details Dispaly

Printing samples

FAQ

Q: What is a paper cup CI flexo printing machine?

A: paper cup CI flexo printing machine is designed for the high-speed printing of various sizes and styles of paper cups and materials. It uses a continuous ink supply system to ensure accurate and consistent printing quality across large quantities of cups.

Q: How does a paper cup CI flexo printing machine work?

A:The machine operates using a rotating cylinder that transfers ink to the cup material as it moves through the machine. The cups are fed into the machine and passed through the ink application and curing process before being ejected and collected for further processing.

Q: What types of ink are used in a paper cup C.I. flexo printing machine?

A:Different types of inks can be used in a paper cup CI flexo printing machine, depending on the cup material used and the design requirements. Common types of inks used include water-based inks, UV-curable inks, and solvent-based inks.

To frequently enhance the management process by virtue of your rule of “sincerely, good religion and good quality are the base of company development”, we greatly absorb the essence of associated solutions internationally, and regularly produce new goods to meet the needs of shoppers for 18 Years Factory 2 4 6 8 Color Flexographic Carton Box Plastic Paper Bag Flexo Printing Machinery Roll Flexo Paper Bag Printing Machine, With a wide range, good quality, fair rates and great services, we are going to be your ideal small business partner. We welcome new and outdated prospects from all walks of lifestyle to get in touch with us for future company associations and achieving mutual accomplishment!

18 Years Factory Flexographic Printers and ci Flexographic Printer Machine, With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the have to have of customers to meet the requirement of customers.