18 Years Factory Machine Flexo - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong

18 Years Factory Machine Flexo - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong

18 Years Factory Machine Flexo - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong Detail:

technical specifications

| Model | CHCI4-600F | CHCI4-800F | CHCI4-1000F | CHCI4-1200F |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-800mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Function Description

- Double station unwinding

- Full servo Printing system

- Pre registration function

- Production menu memory function

- Start up and shut down automatic clutch pressure function

- Automatic pressure adjustment function in the process of printing speed up

- Chamber doctor blade quantitative ink supply system

- temperature control and centralized drying after printing

- EPC before printing

- It has cooling function after printing

- Double station winding.

Double Station Turret Unwinding

Automatic EPC system is configured before printing

Automatic correction of edge position: Automatic EPC system is configured before printing

Automatic correction of edge position: set up the rectification system of four roller automatic EPC ultrasonic probe with full operation before printing, which has manual / automatic / central return function, and the left and right translation can be adjusted

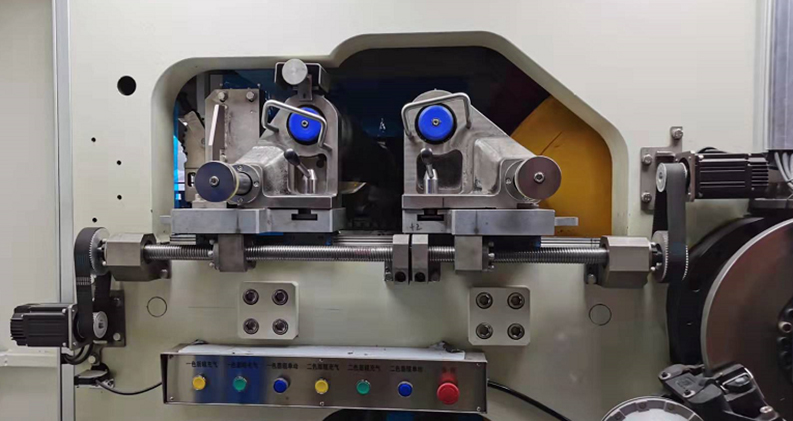

Pressure regulation

The printing pressure has the function of fast forward and backward, which can realize fast movement and precise adjustment

Doctor blade and ink supply system

It is easy to replace the doctor blade and the seal block of the cavity in chamber doctor blade type, and cleaning is convenient.

Sleeve Syetem

Printing Cylinder sleeve imported from Europe

Sleeve ceramic anilox roller

Central drying system

- The length of the horizontal drying box is 4.5m

- Maximum hot air temperature 80℃ (room temperature 20℃)

- Wind speed of drying channel 5~30m/s

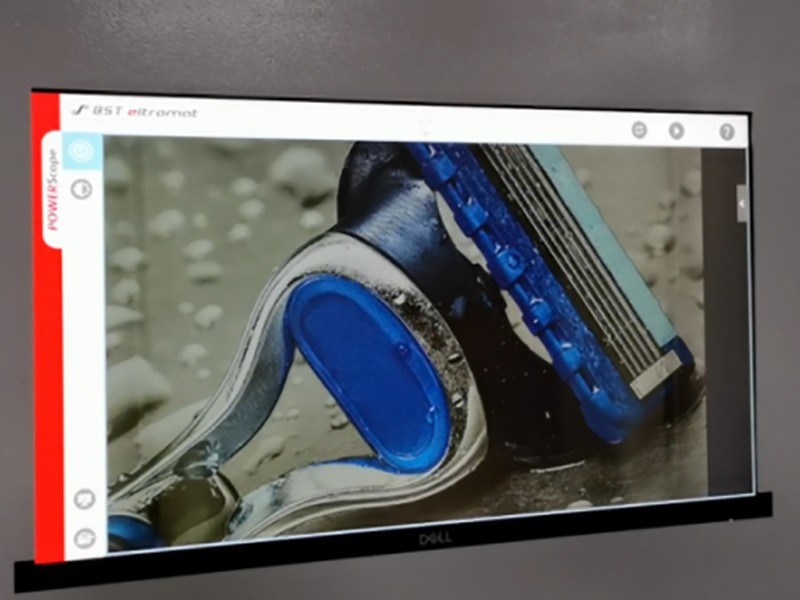

Video Inspection System

Double Station Turret Rewinding

Printing Sample

Product detail pictures:

Related Product Guide:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for 18 Years Factory Machine Flexo - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong , The product will supply to all over the world, such as: Czech, Plymouth, kazan, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!