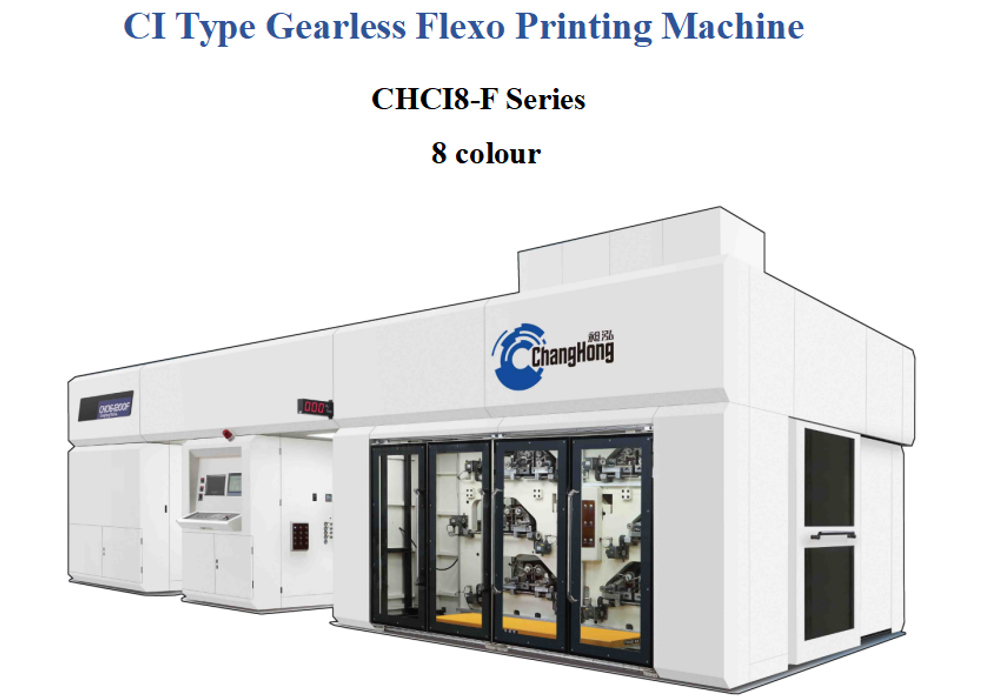

2022 Latest Design Flexographic Printing Technology - High speed 8 colour gearless CI flexo printing machine – Changhong

2022 Latest Design Flexographic Printing Technology - High speed 8 colour gearless CI flexo printing machine – Changhong

2022 Latest Design Flexographic Printing Technology - High speed 8 colour gearless CI flexo printing machine – Changhong Detail:

technical specifications

| Model | CHCI8-600F | CHCI8-800F | CHCI8-1000F | CHCI8-1200F |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-800mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Function Description

- Double station unwinding

- Full servo Printing system

- Pre registration function

- Production menu memory function

- Start up and shut down automatic clutch pressure function

- Automatic pressure adjustment function in the process of printing speed up

- Chamber doctor blade quantitative ink supply system

- temperature control and centralized drying after printing

- EPC before printing

- It has cooling function after printing

- Double station winding.

Double Station Turret Unwinding

Tension control: Using ultra-light floating roller control, automatic tension compensation, closed loop control (low friction cylinder position Detection, precise pressure regulating valve control, automatic alarm or shutdown when the roll diameter reaches the set value)

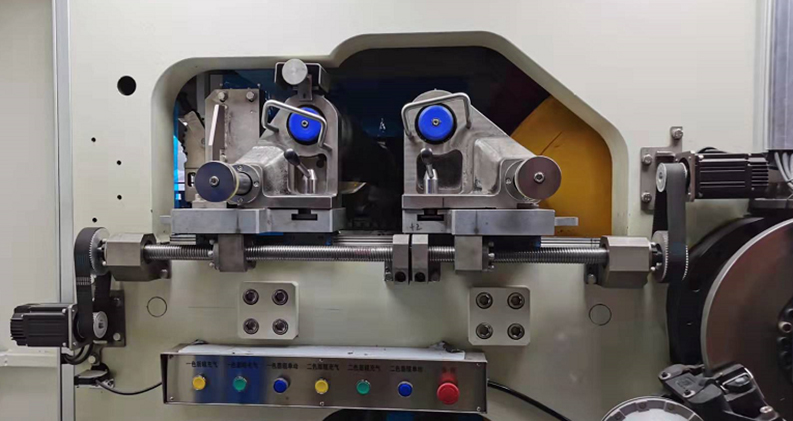

Pressure regulation

The pressure between the anilox roller and the printing plate roller is driven by 2 servo motors for each color, and the pressure is adjusted by ball screws and upper and lower double linear guides, with position memory function

Doctor blade and ink supply system

Aluminum alloy profile doctor blade cavity, seal ink, reduce solvent volatilization, keep ink viscosity and clean.

Sleeve Syetem

Printing Cylinder sleeve imported from Europe

Sleeve ceramic anilox roller

Central drying system

Intelligent continuous constant temperature control, fully enclosed structure, air box adopts heat preservation structure.

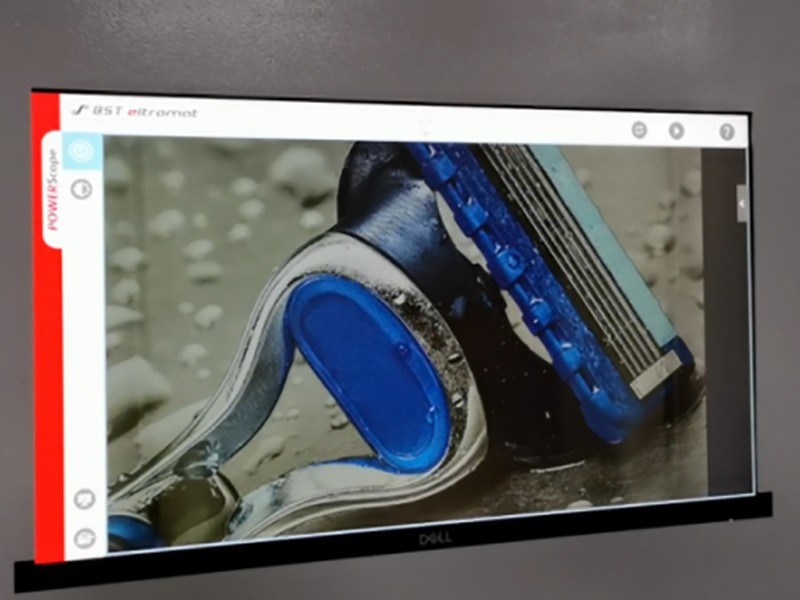

Video Inspection System

Double Station Turret Rewinding

Printing Sample

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for 2022 Latest Design Flexographic Printing Technology - High speed 8 colour gearless CI flexo printing machine – Changhong , The product will supply to all over the world, such as: United Arab emirates, Tajikistan, San Diego, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!