4 color corona treatment stack type flexo Printing Machine for plastic bags

4 color corona treatment stack type flexo Printing Machine for plastic bags

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

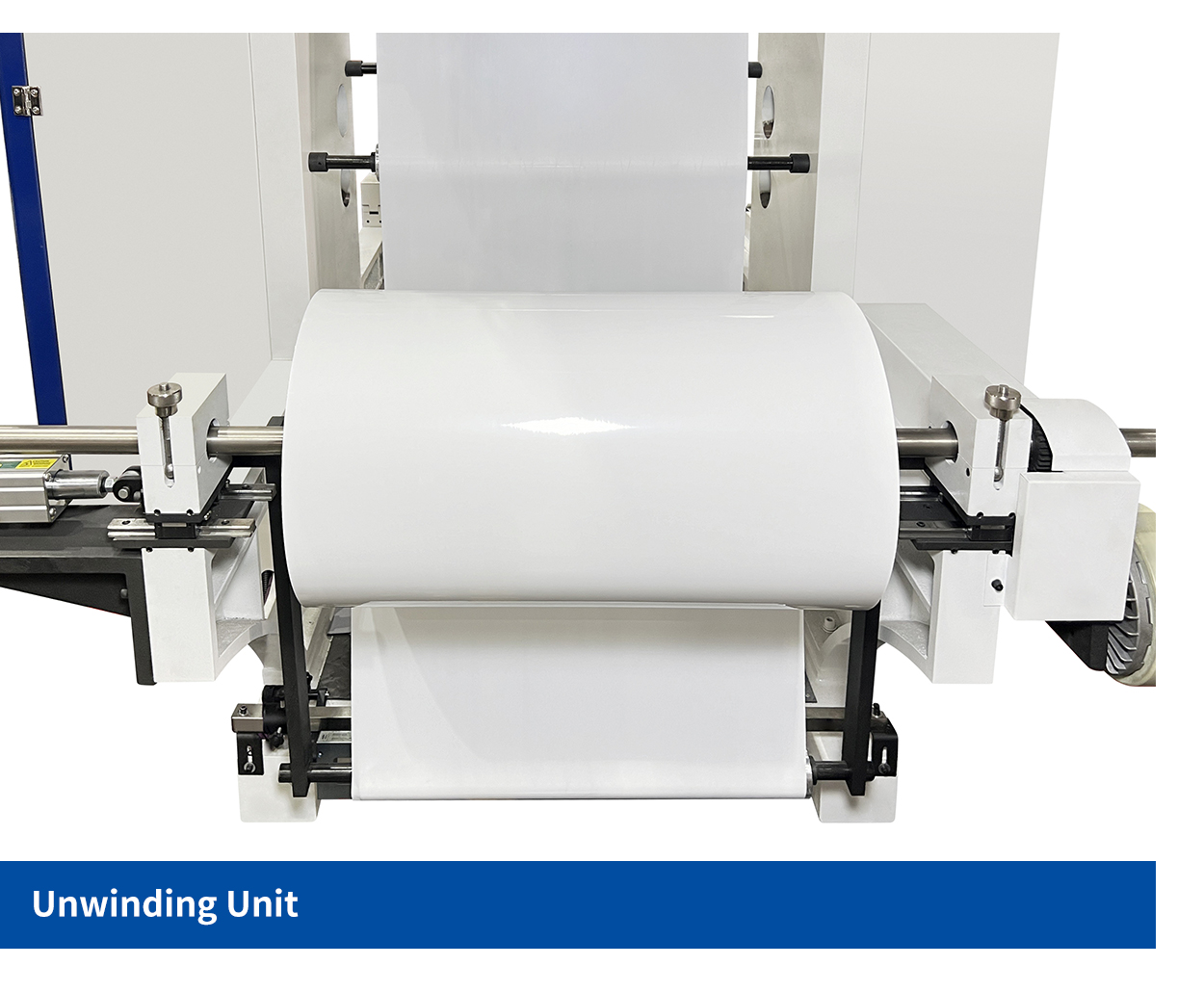

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

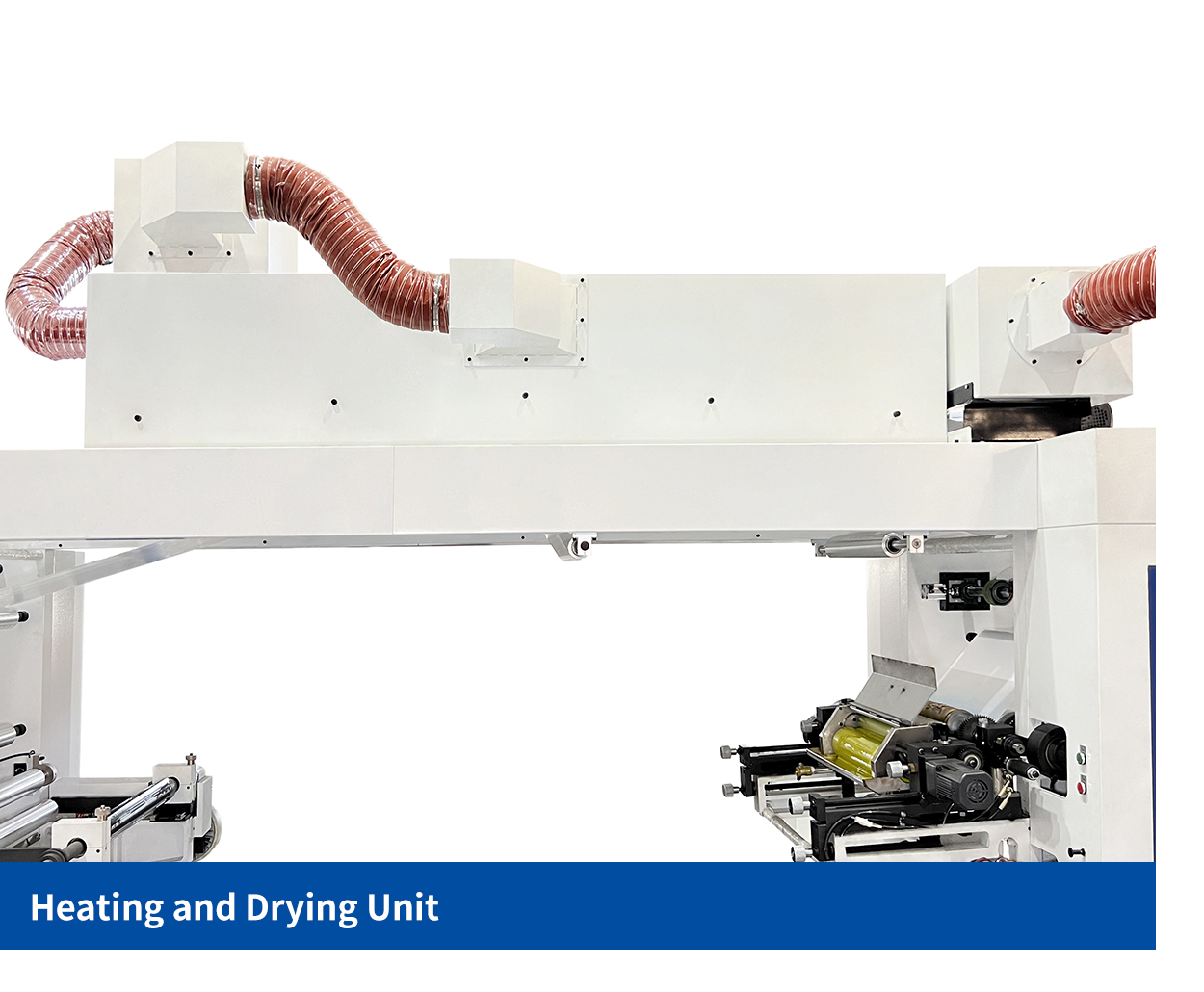

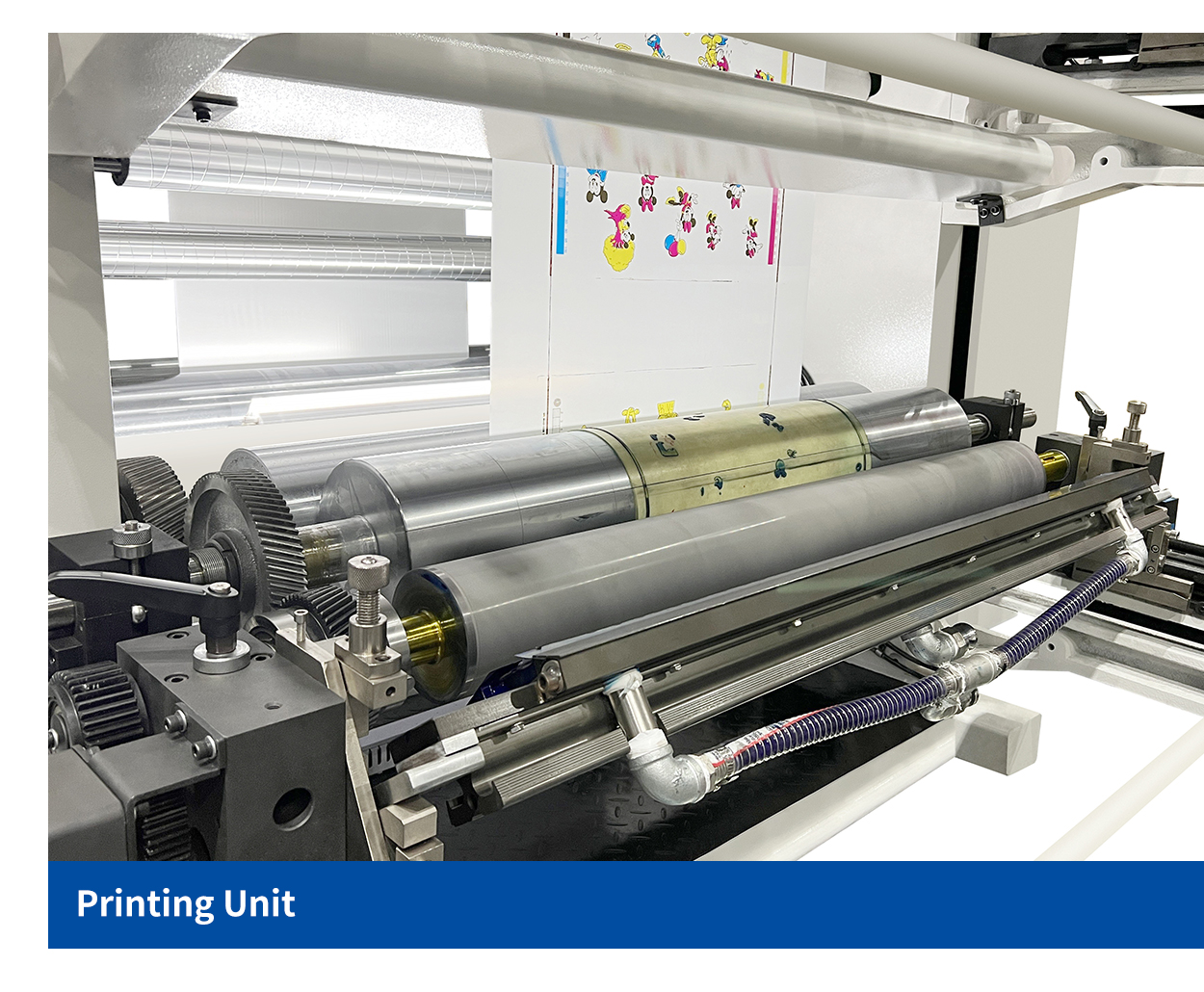

● The corona treatment stack flexographic printing machine is an advanced technology used in the printing industry to produce a wide range of high-quality products such as paper bags, labels, food packaging, medicine packaging and much more.

● The main advantage of this machine is the ability to treat the surface of the printing material with corona. This means that a significant improvement in print quality occurs. Corona is a surface treatment technology used to increase the surface energy of the surface of printing materials, allowing inks and adhesives to better adhere to the surface of the substrate.

● Another important advantage of this machine is its flexibility. It can print on a wide variety of materials, from paper to plastic, and on a wide range of products of different sizes and shapes. In addition, it can be used in a wide variety of applications, from labels to high-quality packaging.

● In addition to producing high-quality prints, the corona treatment stack flexographic printing machine can also be used to produce high-speed prints. This is because prints can be produced at high speed, meaning that large quantities of products can be produced in a short time.

Details Dispaly

sample