6 color central drum ci Flexo Printing Machine for PE/PP/ PET/PVC

6 color central drum ci Flexo Printing Machine for PE/PP/ PET/PVC

technical specifications

| Model | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

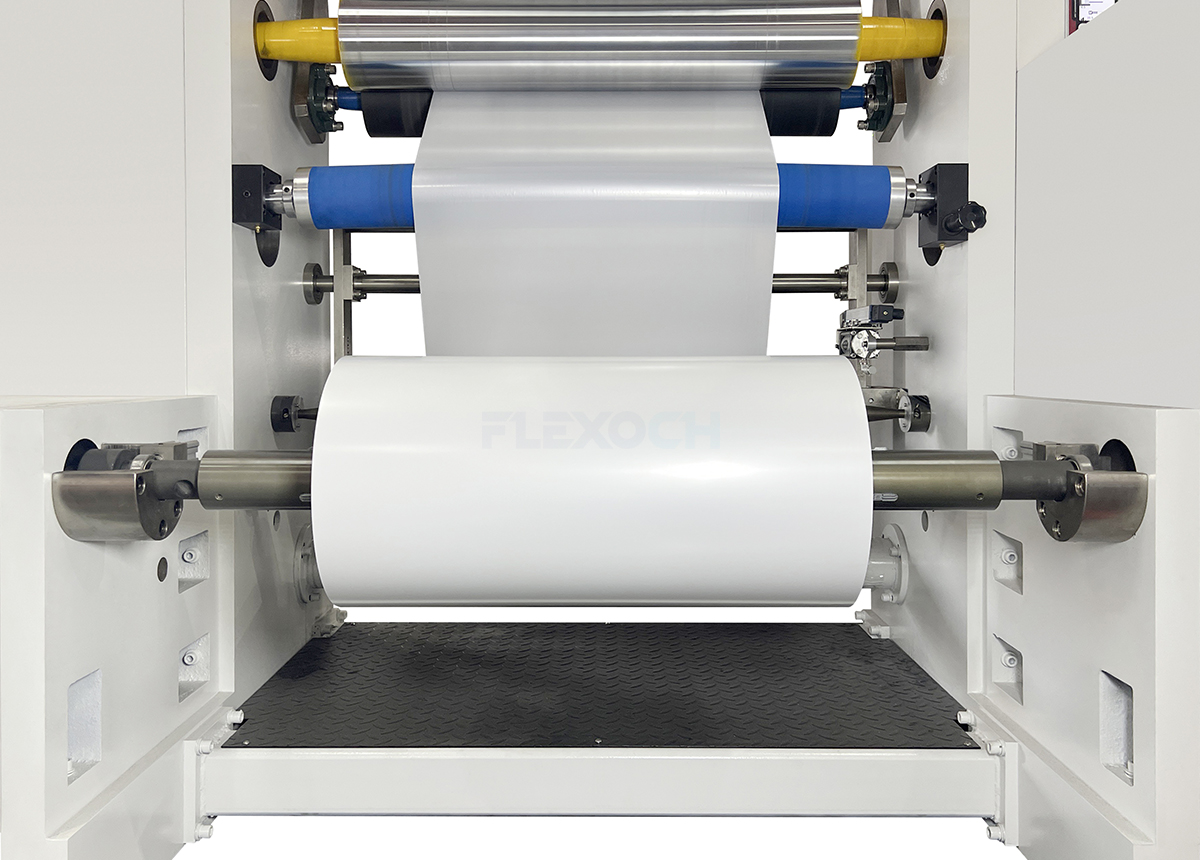

● Central Impression (CI) technology:The ci flexo printing machine adopts an integrated central impression cylinder design to ensure that the 6 color printing registration accuracy is ≤±0.1mm. Even at high speed (up to 300m/min), it can achieve flawless pattern transition, meeting the high requirements for color levels in food packaging, daily chemical labels, etc.

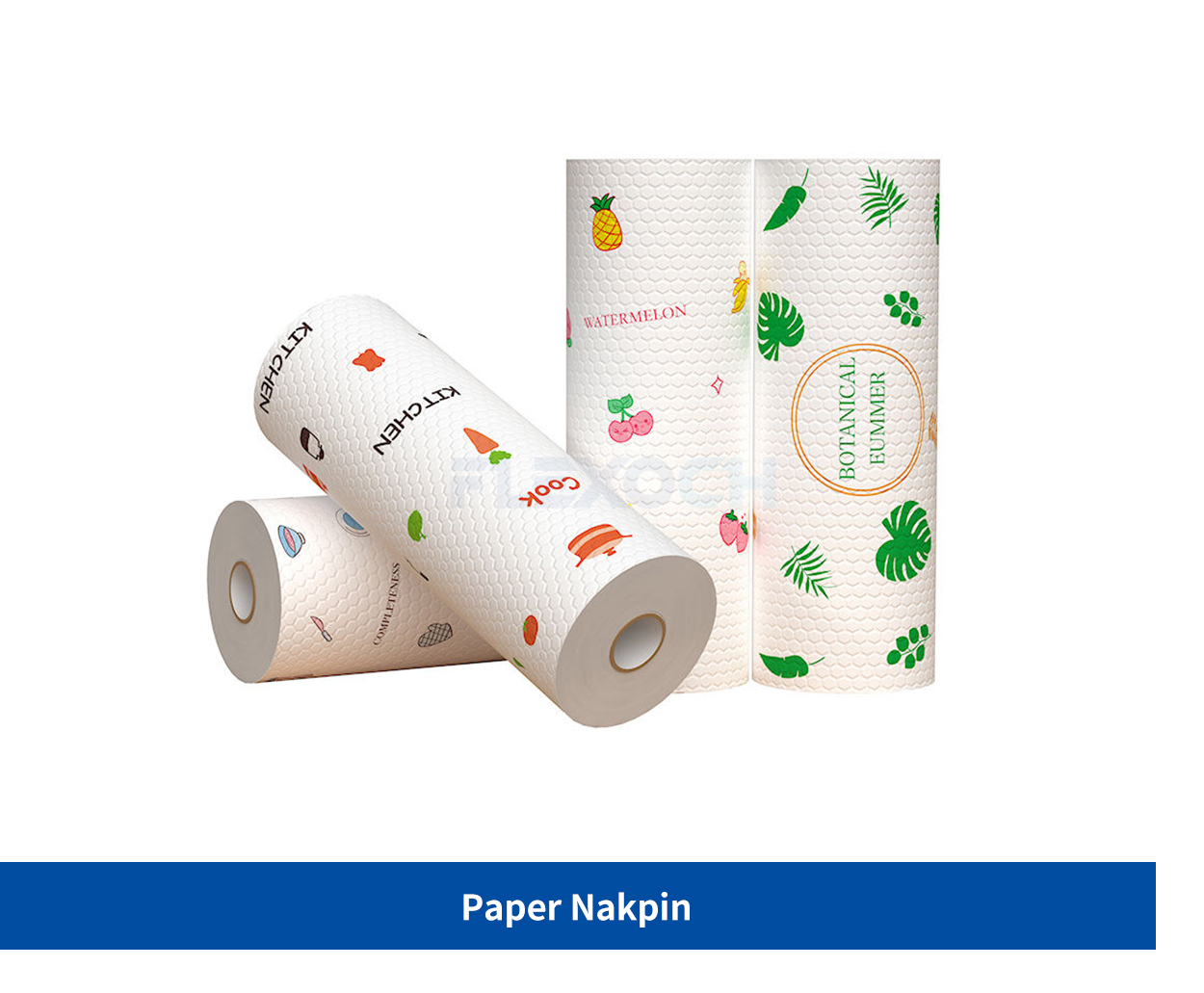

● Full material compatibility: The ci flexo printing machine is suitable for a variety of film substrates and various materials, and can easily cope with the diversified production needs of flexible packaging bags, shrink films, labels, etc.

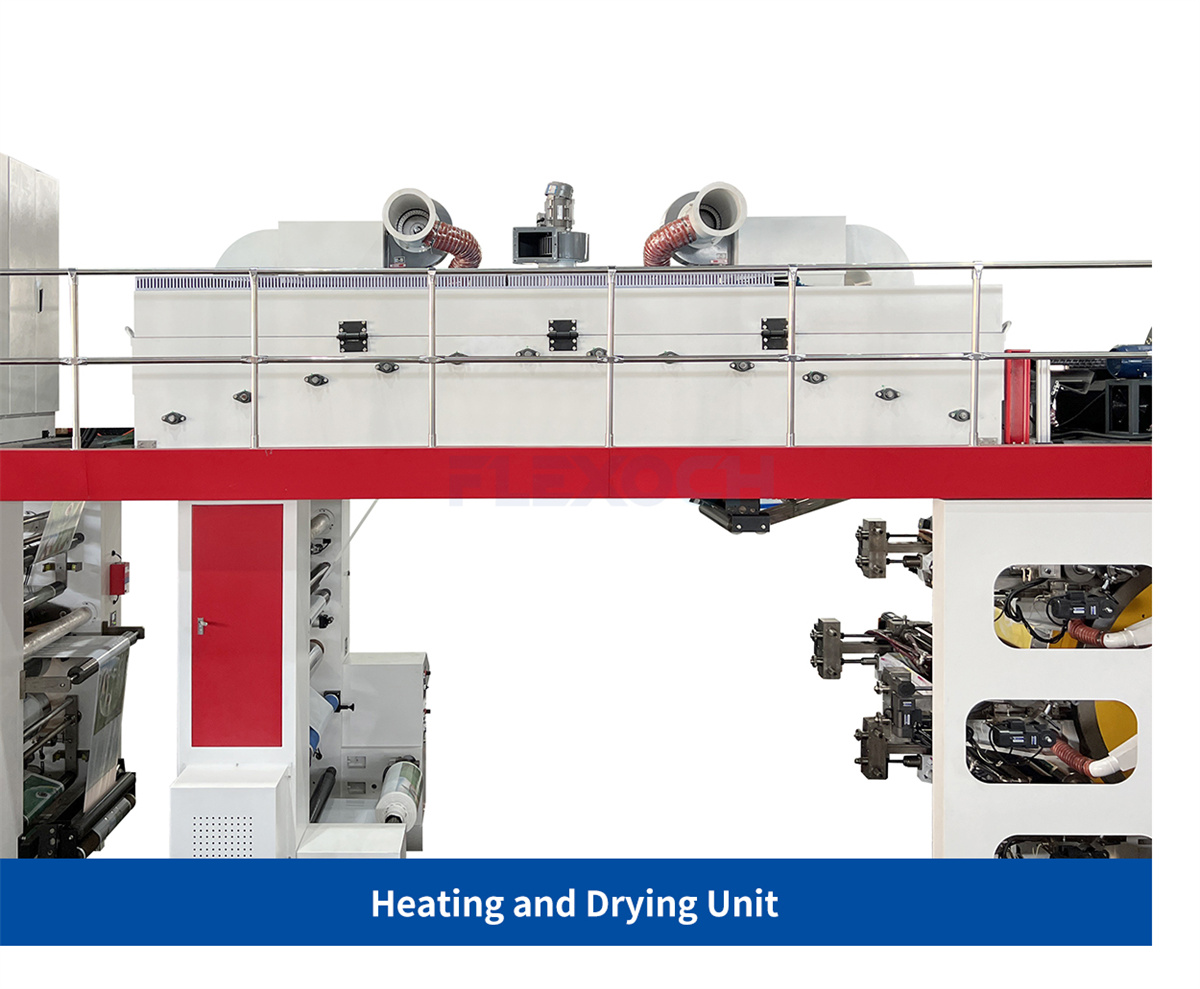

● Environmentally friendly and efficient printing: The flexo printing press supports water-based inks and UV-curing inks, and VOC emissions are far lower than industry standards. Combined with an intelligent drying system, it balances environmental responsibility and economic benefits to achieve sustainable high production.

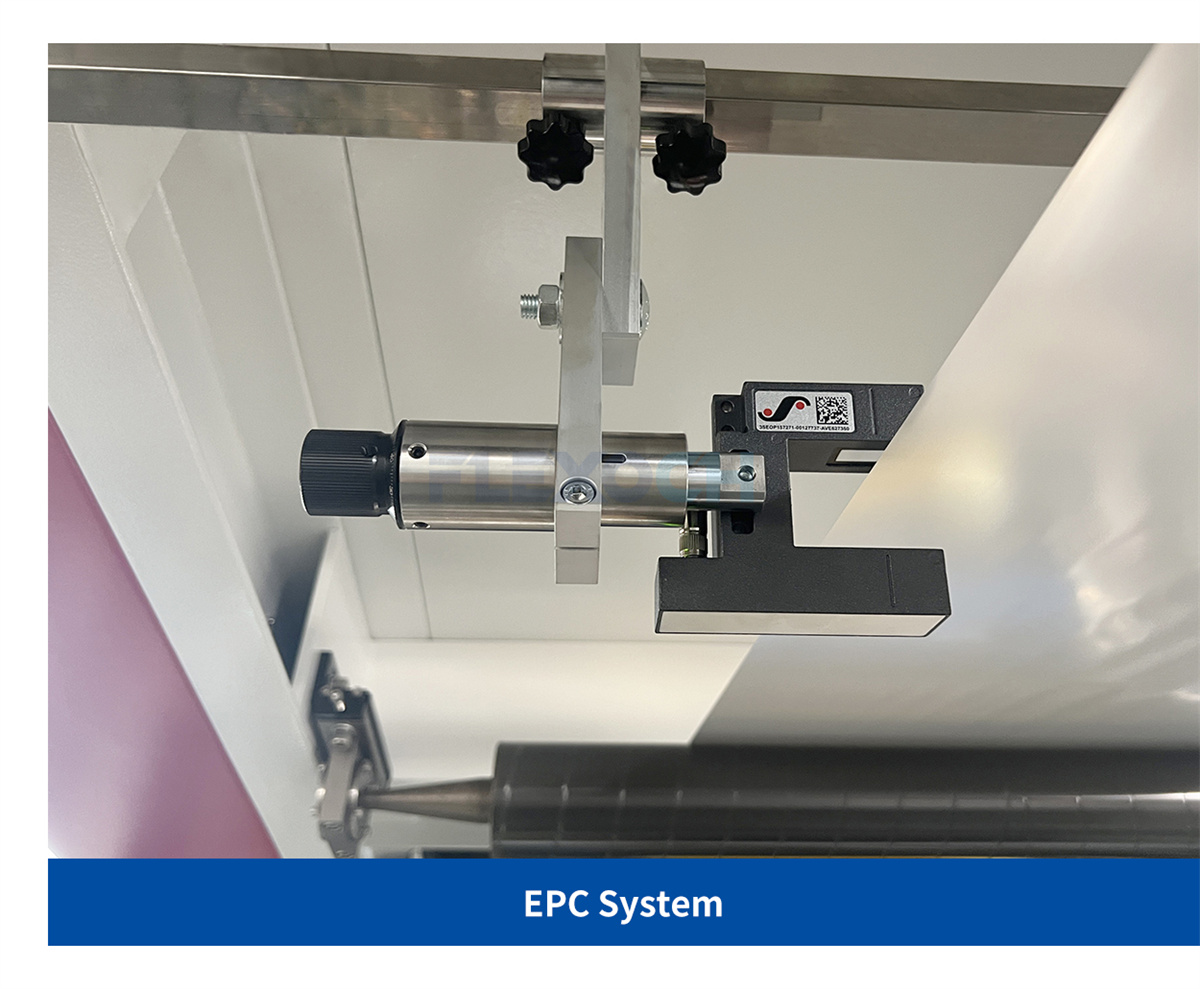

● Intelligent operation experience: The central drum flexo printing machine adopts a full touch screen PLC control system, one-button preset parameters, and fast plate change (≤15 minutes); closed-loop tension control to prevent film wrinkling and stretching deformation.

Details Dispaly

sample

Packaging and Delivery