Best Price on 8 Colour Stack Flexo Printing Machine For Film - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong

Best Price on 8 Colour Stack Flexo Printing Machine For Film - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong Detail:

technical specifications

| Model | CHCI4-600F | CHCI4-800F | CHCI4-1000F | CHCI4-1200F |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-800mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Function Description

- Double station unwinding

- Full servo Printing system

- Pre registration function

- Production menu memory function

- Start up and shut down automatic clutch pressure function

- Automatic pressure adjustment function in the process of printing speed up

- Chamber doctor blade quantitative ink supply system

- temperature control and centralized drying after printing

- EPC before printing

- It has cooling function after printing

- Double station winding.

Double Station Turret Unwinding

Automatic EPC system is configured before printing

Automatic correction of edge position: Automatic EPC system is configured before printing

Automatic correction of edge position: set up the rectification system of four roller automatic EPC ultrasonic probe with full operation before printing, which has manual / automatic / central return function, and the left and right translation can be adjusted

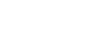

Pressure regulation

The printing pressure has the function of fast forward and backward, which can realize fast movement and precise adjustment

Doctor blade and ink supply system

It is easy to replace the doctor blade and the seal block of the cavity in chamber doctor blade type, and cleaning is convenient.

Sleeve Syetem

Printing Cylinder sleeve imported from Europe

Sleeve ceramic anilox roller

Central drying system

- The length of the horizontal drying box is 4.5m

- Maximum hot air temperature 80℃ (room temperature 20℃)

- Wind speed of drying channel 5~30m/s

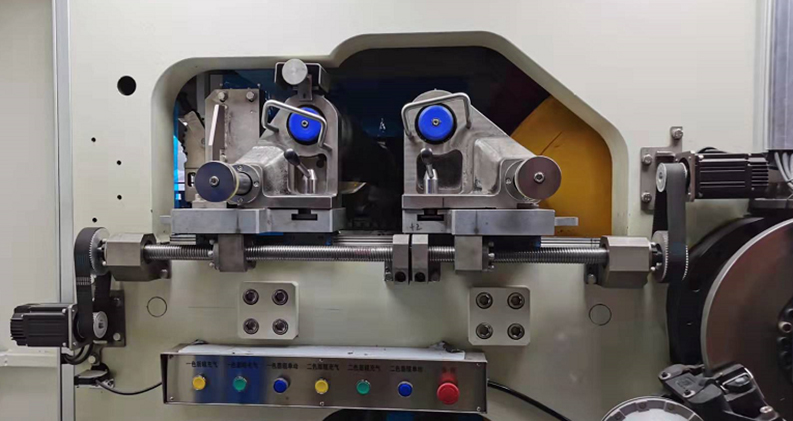

Video Inspection System

Double Station Turret Rewinding

Printing Sample

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Best Price on 8 Colour Stack Flexo Printing Machine For Film - High speed 4 colour gearless CI flexo printing machine with servo motor – Changhong , The product will supply to all over the world, such as: Buenos Aires, South Korea, Ghana, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.