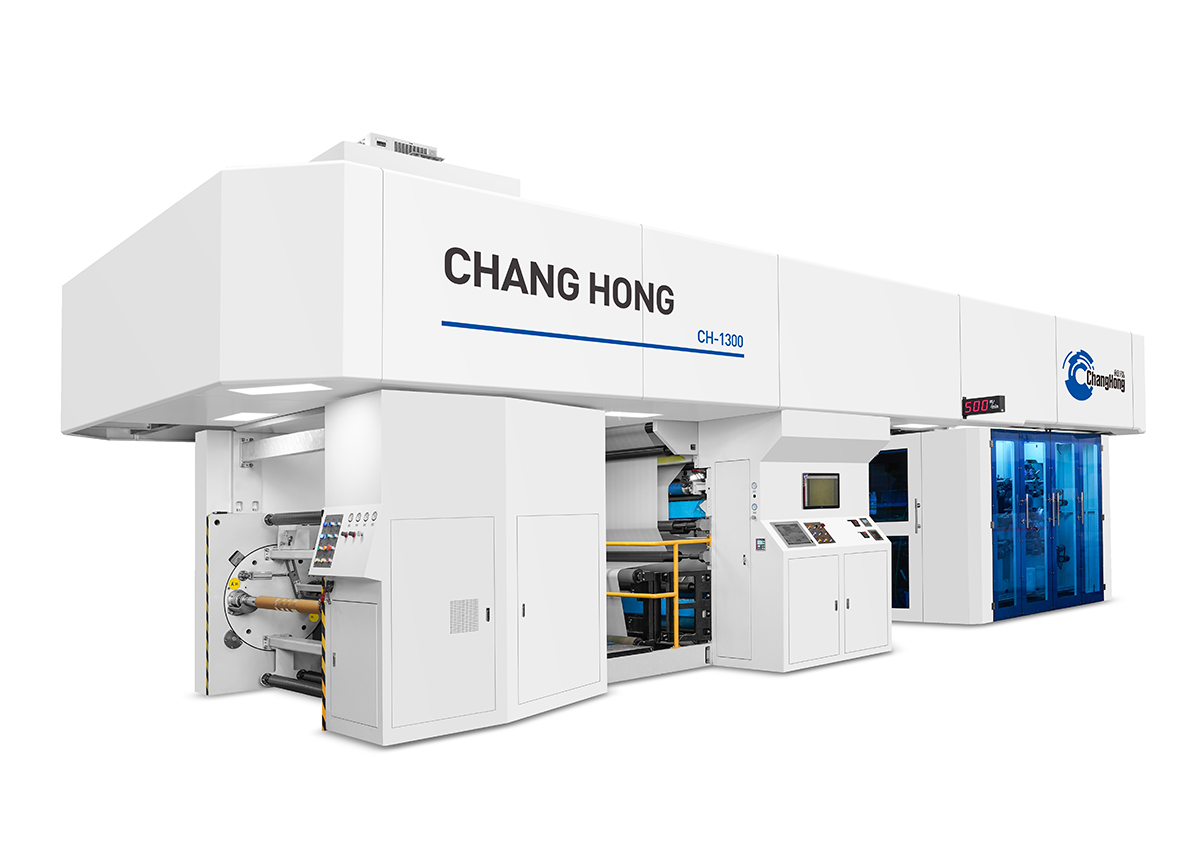

Cheapest Factory 4/6/8 Color Flexo Printing and Flexo printing Machine for Paper Cup Production

Cheapest Factory 4/6/8 Color Flexo Printing and Flexo printing Machine for Paper Cup Production

We’re also specializing in strengthening the things management and QC method to ensure that we could maintain great gain while in the fiercely-competitive business for Cheapest Factory 4/6/8 Color Flexo Printing and Flexo printing Machine for Paper Cup Production, The continual availability of substantial grade products and solutions in combination with our fantastic pre- and after-sales services ensures strong competitiveness in an increasingly globalized current market.

We’re also specializing in strengthening the things management and QC method to ensure that we could maintain great gain while in the fiercely-competitive business for Flexographic Printing Machine and Flexo Printing Machine, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We’re ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

technical specifications

| Model | CHCI4-600J-Z | CHCI4-800J-Z | CHCI4-1000J-Z | CHCI4-1200J-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High printing speeds: This machine is capable of printing at high speeds, which translates into a higher production of printed materials in a shorter time.

2. Flexibility in printing: The flexibility of flexographic printing allows the use of different types of materials that cannot be printed with other techniques. In addition, parameters and calibrations can also be adjusted to make quick changes in printing and production.

3. Superior printing quality: Flexographic printing of ci paper offers a superior printing quality than other printing techniques, because liquid ink is used instead of toners or printing cartridges.

4. Low production cost: This machine has a low production cost compared to other printing techniques. In addition, the use of water-based inks reduces costs and improves the sustainability of the process.

5. Longer durability of flexographic moulds: The flexographic moulds used in this machine are more durable than those used in other printing techniques, which translates into lower maintenance cost.

Details Dispaly

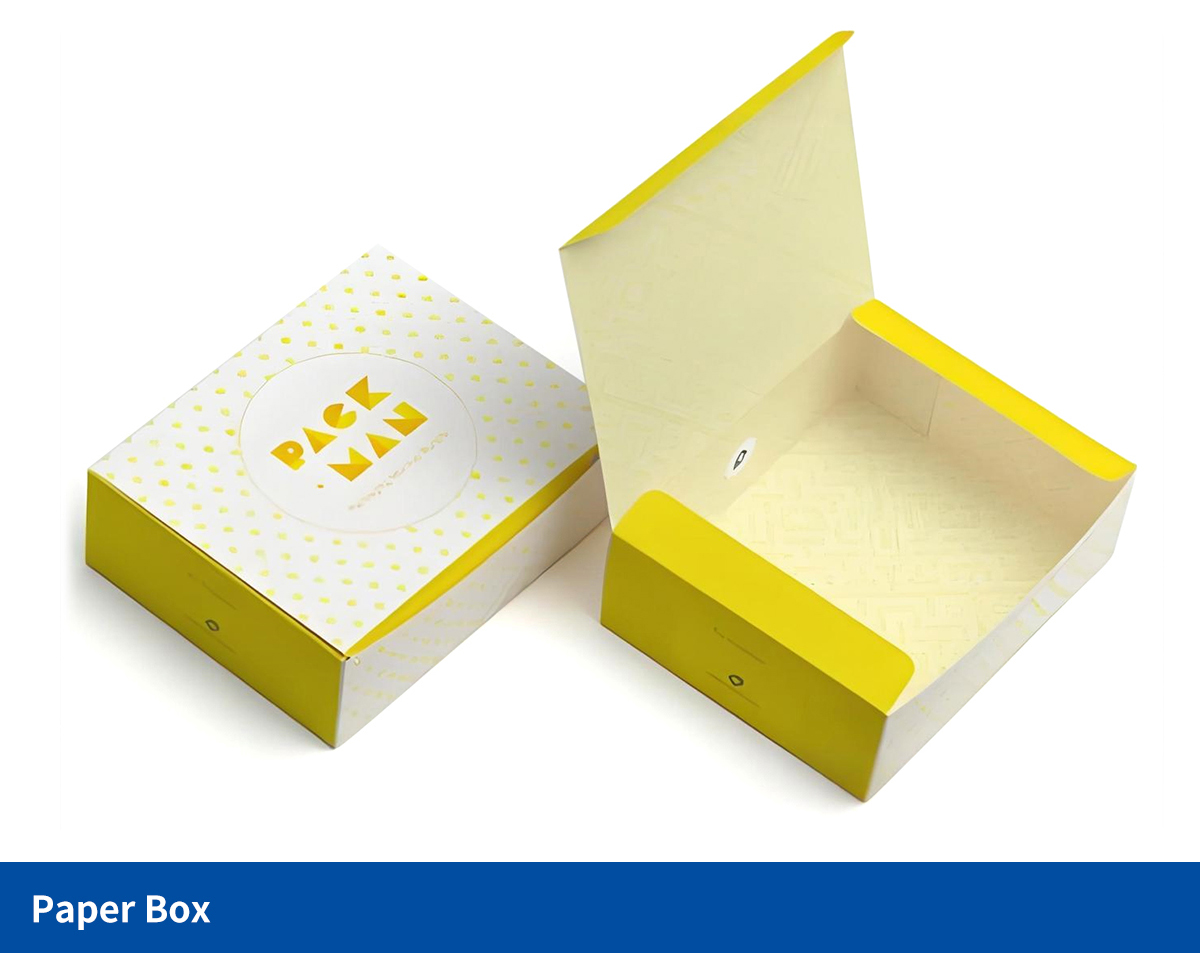

sample

Packaging and Delivery

We’re also specializing in strengthening the things management and QC method to ensure that we could maintain great gain while in the fiercely-competitive business for Cheapest Factory 4/6/8 Color Flexo Printing and Flexo printing Machine for Paper Cup Production, The continual availability of substantial grade products and solutions in combination with our fantastic pre- and after-sales services ensures strong competitiveness in an increasingly globalized current market.

Cheapest Factory flexographic Printing Machine and Flexo printing Machine, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We’re ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.