Factory Selling Machinery for plastic film PE/LDPE/HDPE/CPP Printing Flexo Press Machine Paper Roll to Roll

Factory Selling Machinery for plastic film PE/LDPE/HDPE/CPP Printing Flexo Press Machine Paper Roll to Roll

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Factory Selling Machinery for plastic film PE/LDPE/HDPE/CPP Printing Flexo Press Machine Paper Roll to Roll, Our solutions are regularly supplied to a lot of Groups and lots of Factories. Meanwhile, our solutions are sold to your USA, Italy, Singapore, Malaysia, Russia, Poland, as well as the Middle East.

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Flexo Printing Machine and roll to roll printing machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products and solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

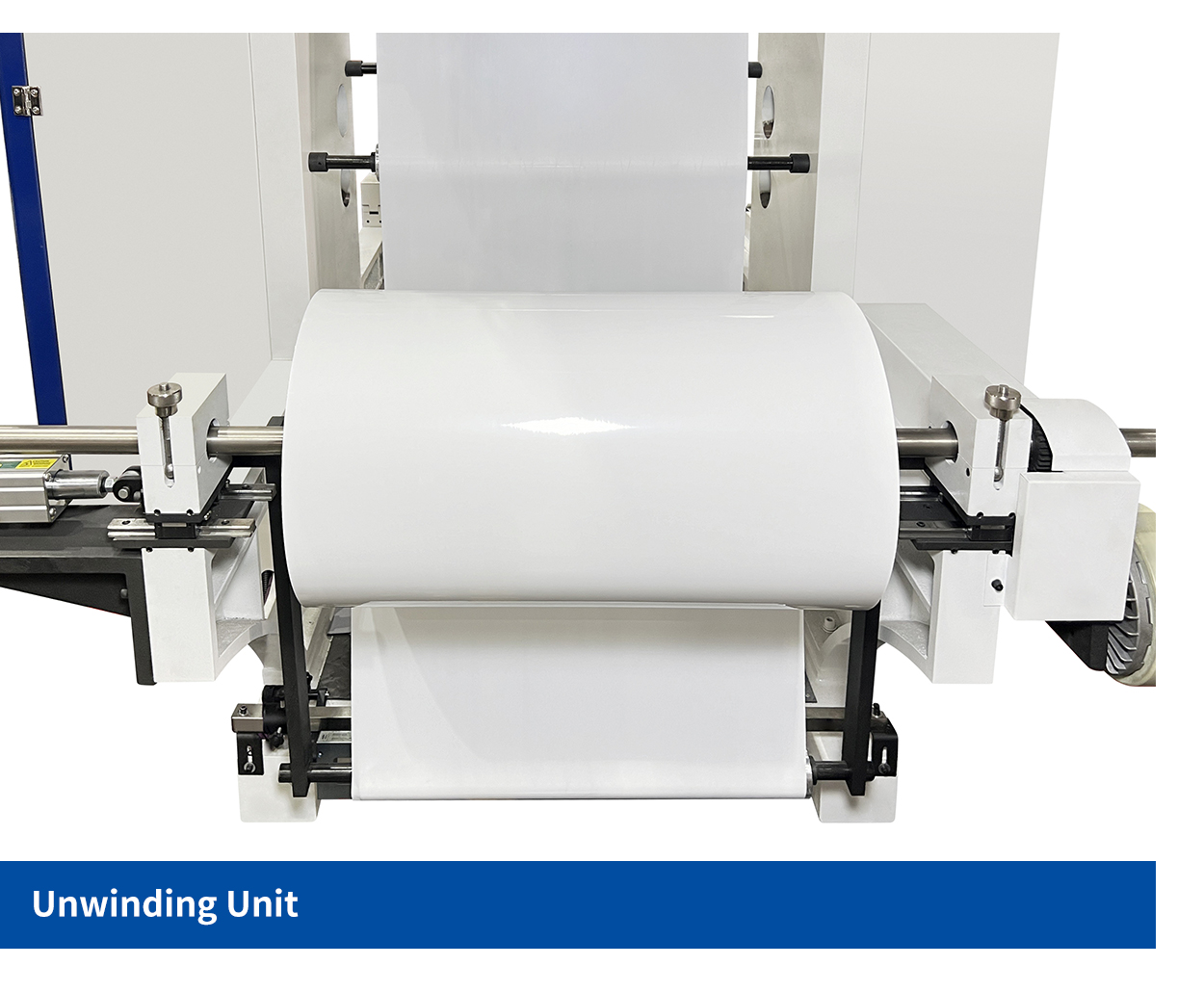

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

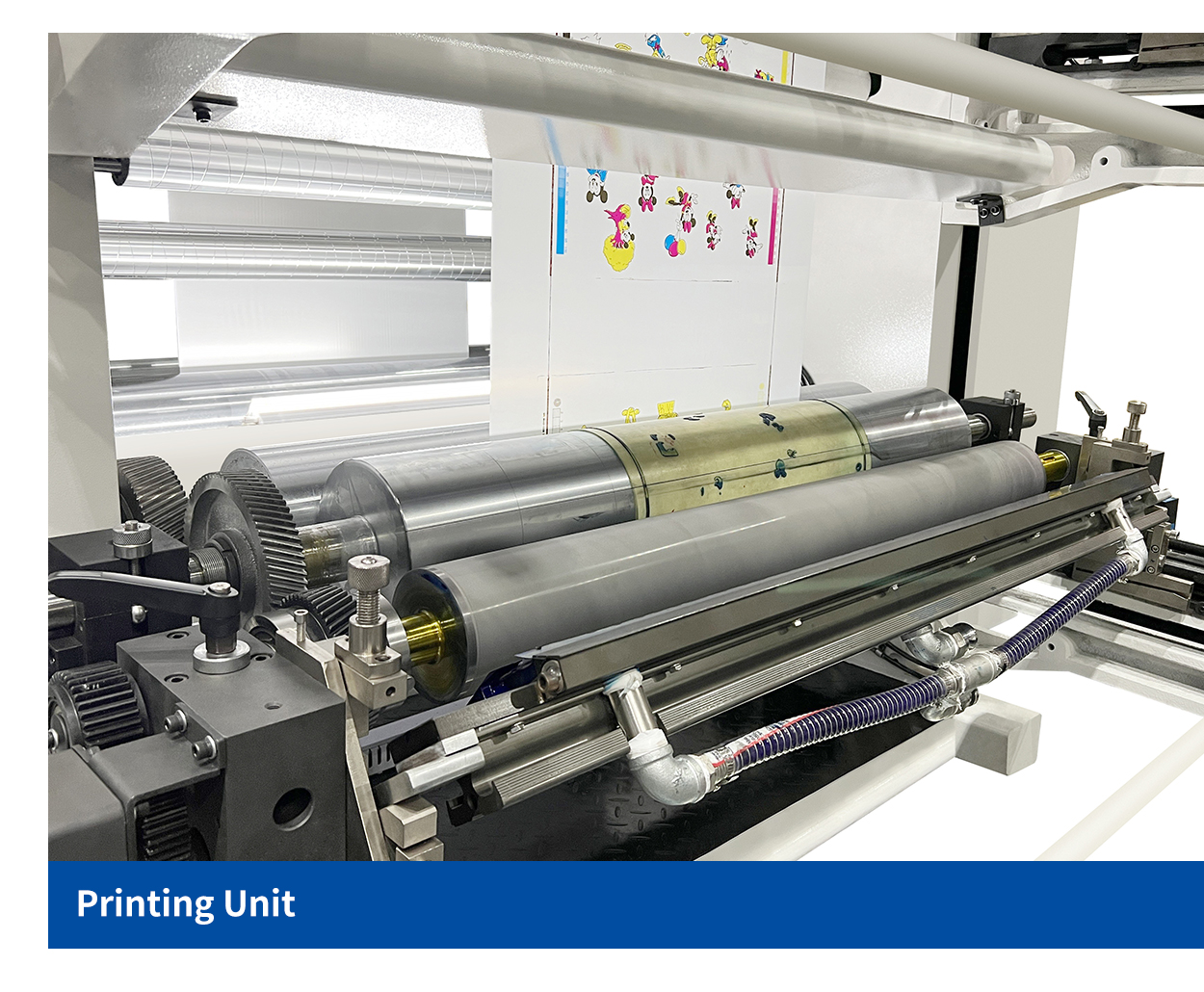

● The corona treatment stack flexographic printing machine is an advanced technology used in the printing industry to produce a wide range of high-quality products such as paper bags, labels, food packaging, medicine packaging and much more.

● The main advantage of this machine is the ability to treat the surface of the printing material with corona. This means that a significant improvement in print quality occurs. Corona is a surface treatment technology used to increase the surface energy of the surface of printing materials, allowing inks and adhesives to better adhere to the surface of the substrate.

● Another important advantage of this machine is its flexibility. It can print on a wide variety of materials, from paper to plastic, and on a wide range of products of different sizes and shapes. In addition, it can be used in a wide variety of applications, from labels to high-quality packaging.

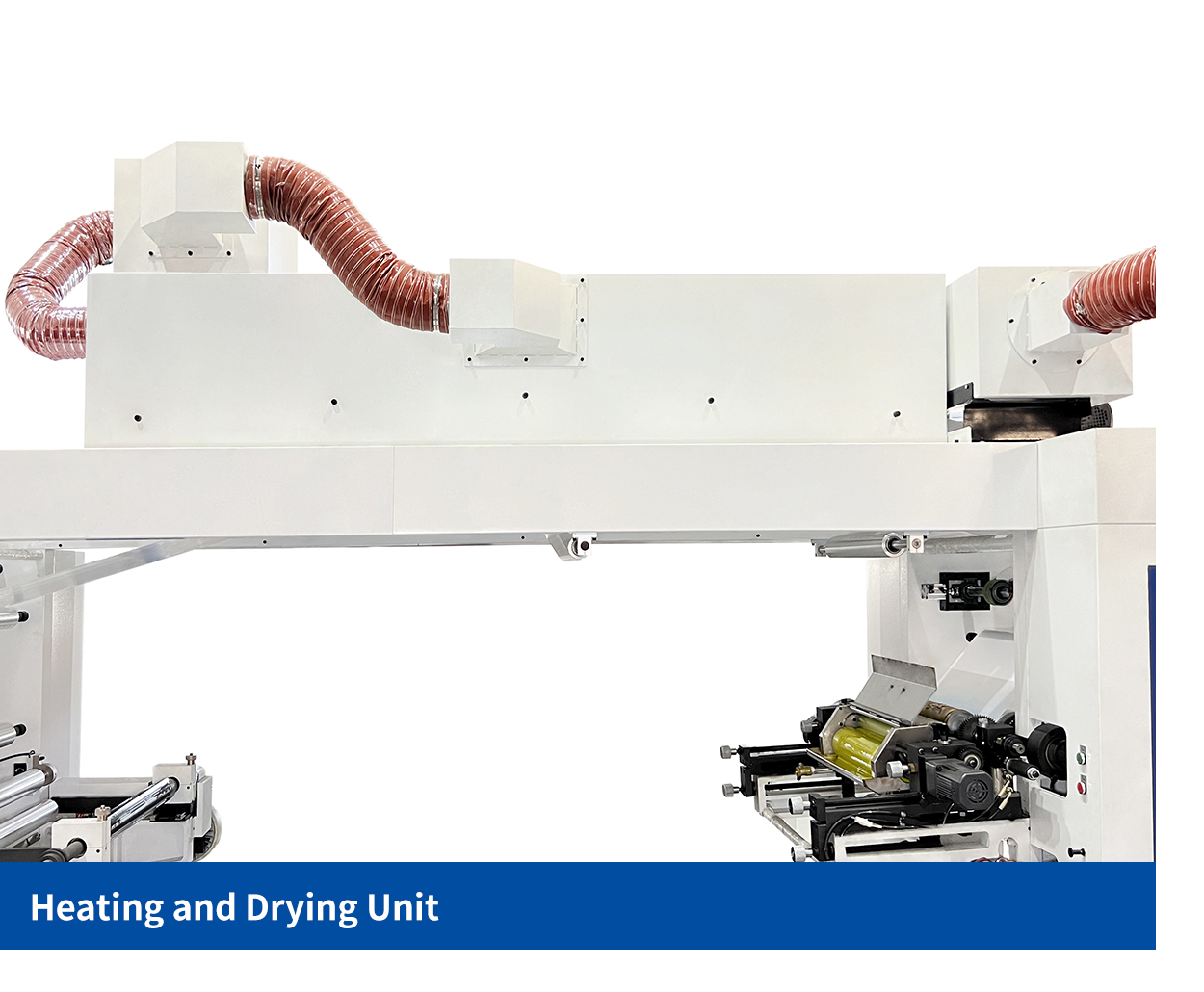

● In addition to producing high-quality prints, the corona treatment stack flexographic printing machine can also be used to produce high-speed prints. This is because prints can be produced at high speed, meaning that large quantities of products can be produced in a short time.

Details Dispaly

sample

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Factory Selling Machinery for plastic film PE/LDPE/HDPE/CPP Printing Flexo Press Machine Paper Roll to Roll, Our solutions are regularly supplied to a lot of Groups and lots of Factories. Meanwhile, our solutions are sold to your USA, Italy, Singapore, Malaysia, Russia, Poland, as well as the Middle East.

Factory Selling Flexo Printing Machine and roll to roll printing machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products and solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.