High Quality 4 6 8 10 Colors Stack BOPP Film Flexo Printing Machine Flexographic Press for LDPE/CPP/BOPP/PE

High Quality 4 6 8 10 Colors Stack BOPP Film Flexo Printing Machine Flexographic Press for LDPE/CPP/BOPP/PE

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for High Quality 4 6 8 10 Colors Stack BOPP Film Flexo Printing Machine Flexographic Press for LDPE/CPP/BOPP/PE, We are wanting ahead to setting up cooperative associations along with you. Please call us for more information and facts.

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for Stack Type Flexo Press Machine and 4 Colors Stack Type Flexo Printing Machine, Today, We are with great passion and sincerity to further fulfill our global customers’ needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

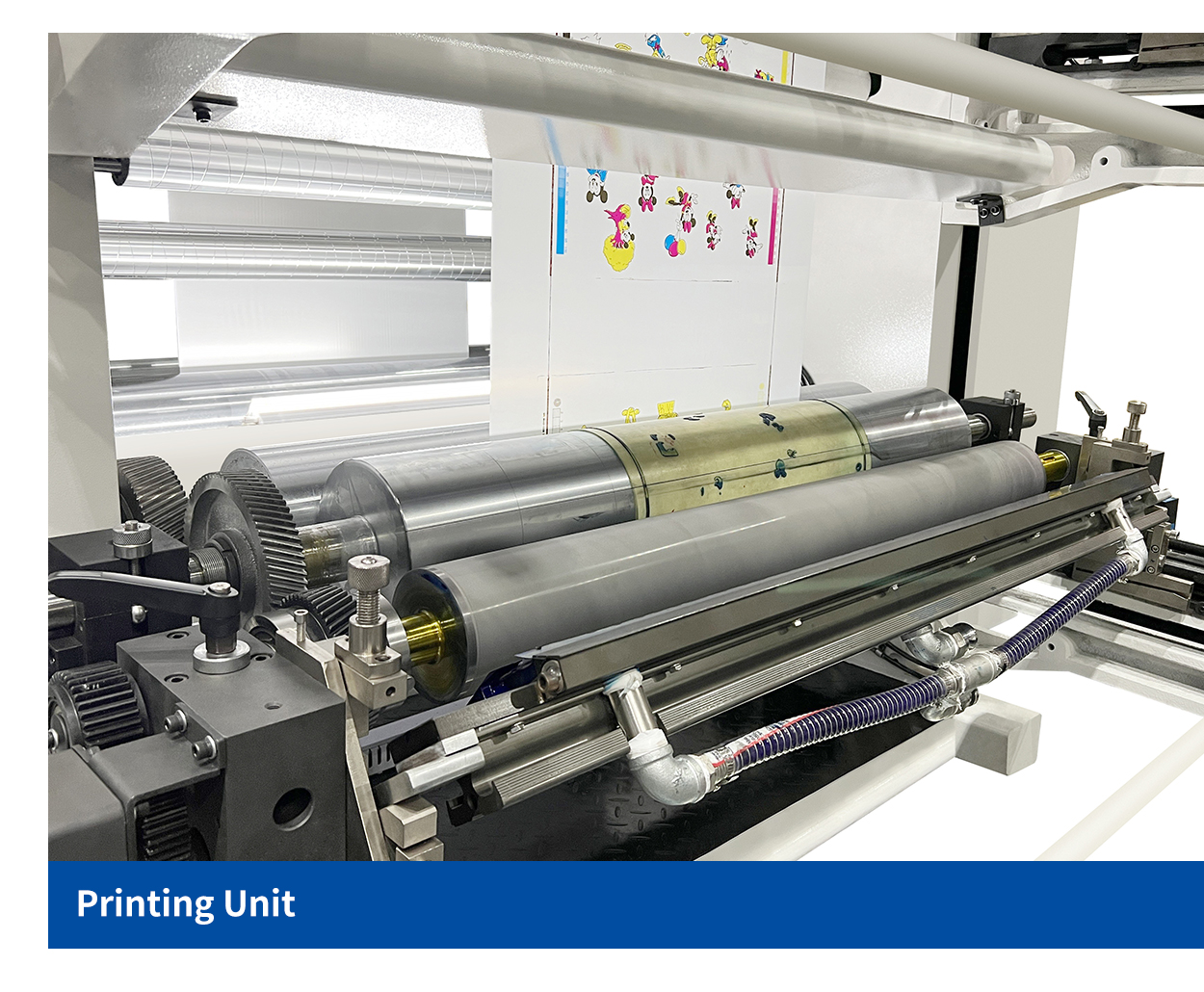

● The corona treatment stack flexographic printing machine is an advanced technology used in the printing industry to produce a wide range of high-quality products such as paper bags, labels, food packaging, medicine packaging and much more.

● The main advantage of this machine is the ability to treat the surface of the printing material with corona. This means that a significant improvement in print quality occurs. Corona is a surface treatment technology used to increase the surface energy of the surface of printing materials, allowing inks and adhesives to better adhere to the surface of the substrate.

● Another important advantage of this machine is its flexibility. It can print on a wide variety of materials, from paper to plastic, and on a wide range of products of different sizes and shapes. In addition, it can be used in a wide variety of applications, from labels to high-quality packaging.

● In addition to producing high-quality prints, the corona treatment stack flexographic printing machine can also be used to produce high-speed prints. This is because prints can be produced at high speed, meaning that large quantities of products can be produced in a short time.

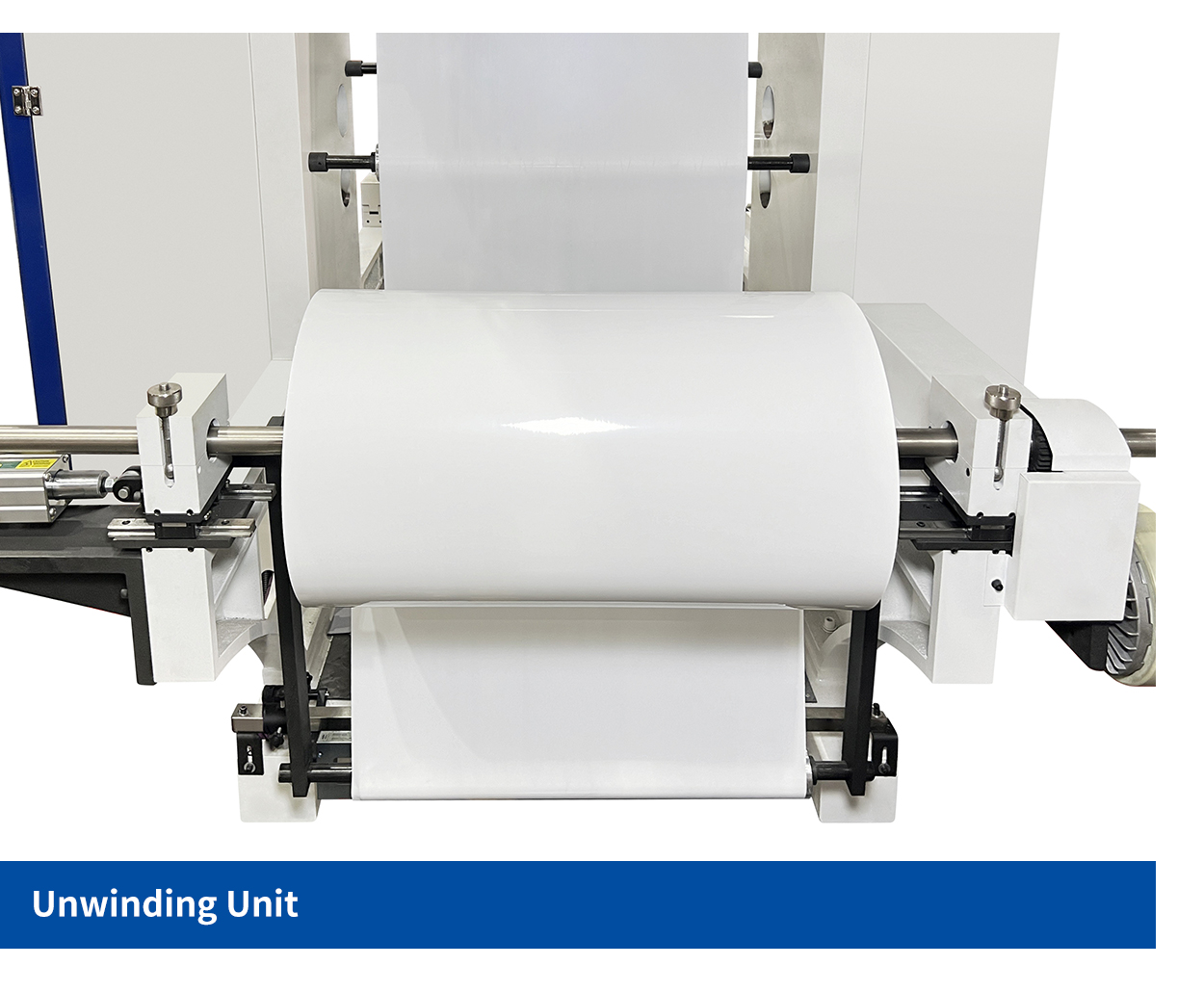

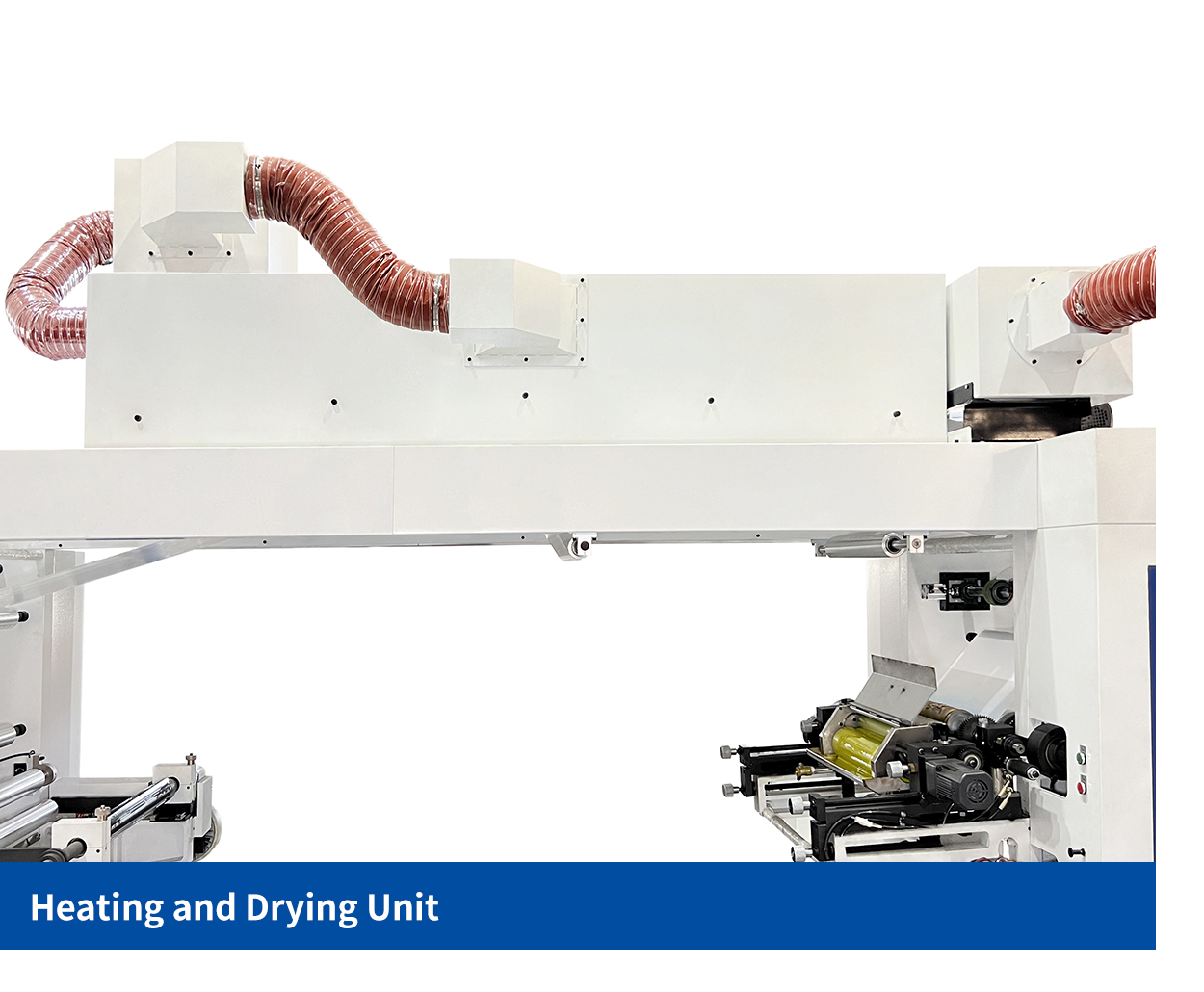

Details Dispaly

sample

Assume full duty to satisfy all requires of our shoppers; obtain continual advancements by promoting the advancement of our clients; grow to be the final permanent cooperative partner of clients and maximize the interests of purchasers for High Quality 4 6 8 10 Colors Stack BOPP Film Flexo Printing Machine Flexographic Press for LDPE/CPP/BOPP/PE, We are wanting ahead to setting up cooperative associations along with you. Please call us for more information and facts.

High Quality Stack Type Flexo Press Machine and 4 Colors Stack Type Flexo Printing Machine, Today, We are with great passion and sincerity to further fulfill our global customers’ needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.