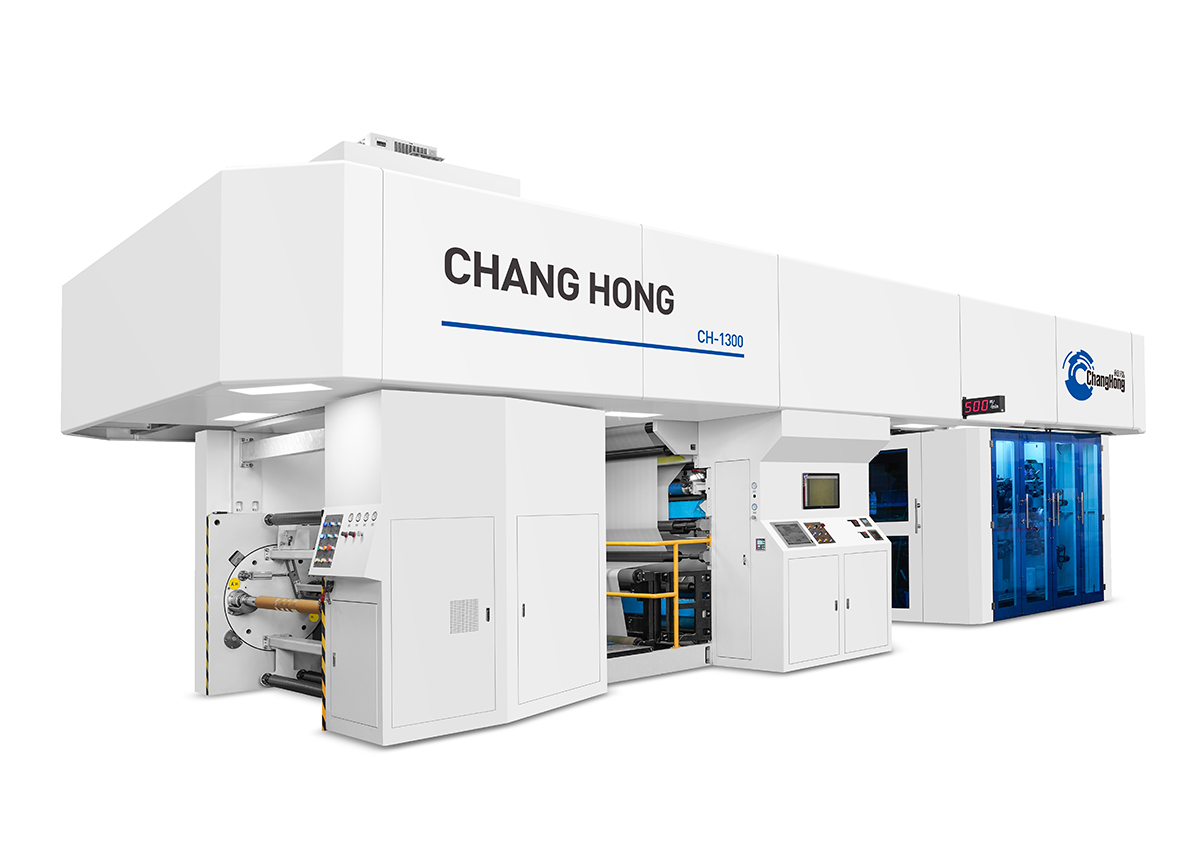

High reputation Flexographic 4 6 8 10 Color Machinery Paper Plastic Roll to Roll stack type Flexography Flexo Press Printing Machine

High reputation Flexographic 4 6 8 10 Color Machinery Paper Plastic Roll to Roll stack type Flexography Flexo Press Printing Machine

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for High reputation Flexographic 4 6 8 10 Color Machinery Paper Plastic Roll to Roll stack type Flexography Flexo Press Printing Machine, We are willing to give you the best suggestions on the designs of your orders in a professional way if you need. In the meantime, we keep on developing new technologies and creating new designs so as to make you ahead in the line of this business.

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for stack type Flexo Printing Machine and Roll to Roll Flexo printing Machine, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we have been looking forward to building up a great business relationship with you.

Technical Specifications

| Model | CH6-600S-S | CH6-800S-S | CH6-1000S-S | CH6-1200S-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 200m/min | |||

| Max. Printing Speed | 150m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Servo drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-1000mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1.Precision and Stability, Outstanding Core Performance

This stack type flexographic printing press utilizes a servo drive system. Each color group is driven by an independent servo motor. Synchronously controlled via digital commands, this eliminates the backlash error and inertial interference associated with traditional mechanical gear drives, ensuring consistent print quality, precise overprinting, and sharp dots.

2.Intelligent Efficiency and Superior Automation

The servo stack type flexographic printing press is equipped with an intelligent automatic feeding system that enables a fully automated process from material loading, threading, to splicing. It supports seamless handling of large rolls and achieves automatic roll change and splicing without stopping operation, ensuring continuous production for long-running and large-volume orders.

3.Efficient Drying, Dramatically Improving Productivity

The innovative drying system is key to boosting productivity. This 6-color stack type flexographic printing machine utilizes a multi-stage, highly efficient drying design, enabling thorough drying of wide-format, thick-ink-covered prints in a very short time.

4.Wide Application and Significant Economies of Scale

The wide-format design directly brings about a significant increase in production capacity. The larger printing width means more products can be produced in a single pass. Furthermore, the wide format provides the equipment with greater printing flexibility, easily meeting the printing needs of a variety of wide-format products and expanding the company’s business capabilities.

Details Dispaly

Printing Sample

![]()

Packaging And Delivery

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for High reputation Flexographic 4 6 8 10 Color Machinery Paper Plastic Roll to Roll stack type Flexography Flexo Press Printing Machine, We are willing to give you the best suggestions on the designs of your orders in a professional way if you need. In the meantime, we keep on developing new technologies and creating new designs so as to make you ahead in the line of this business.

High reputation stack type Flexo Printing Machine and Roll to Roll Flexo printing Machine, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we have been looking forward to building up a great business relationship with you.