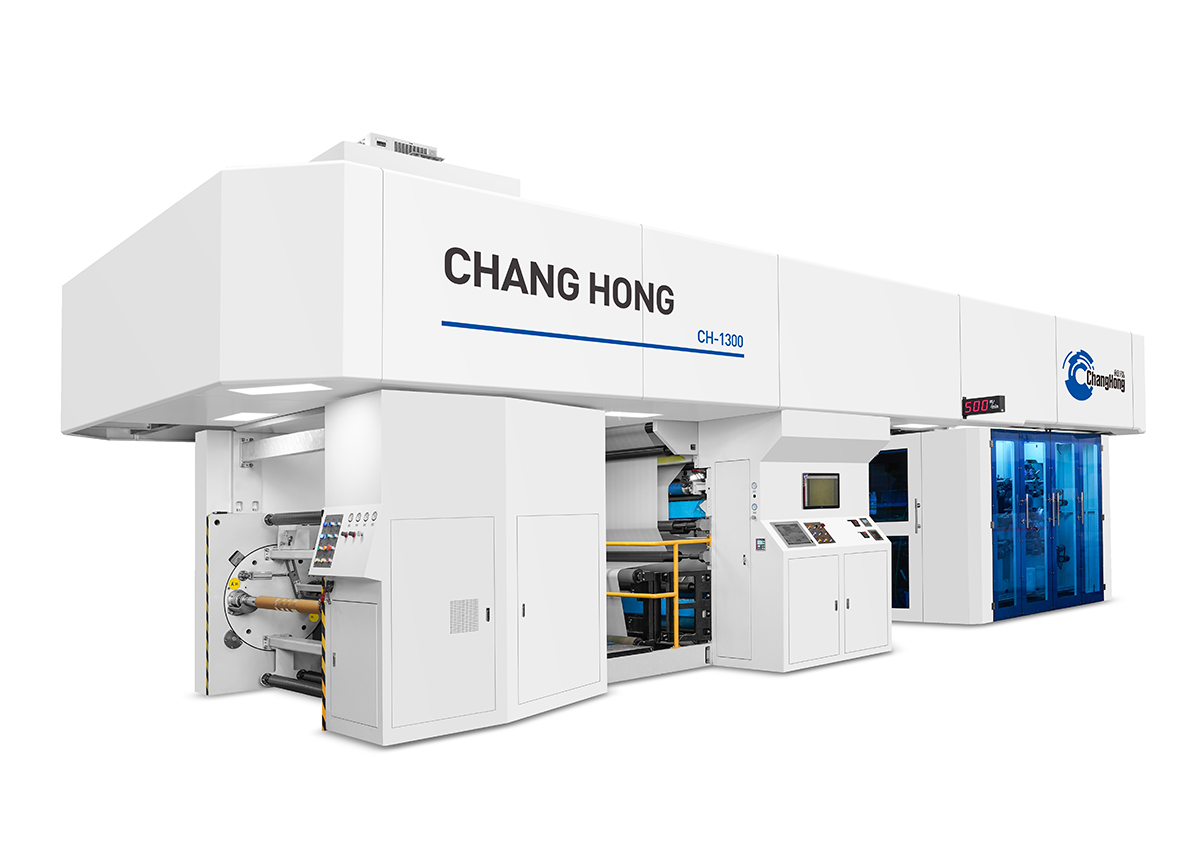

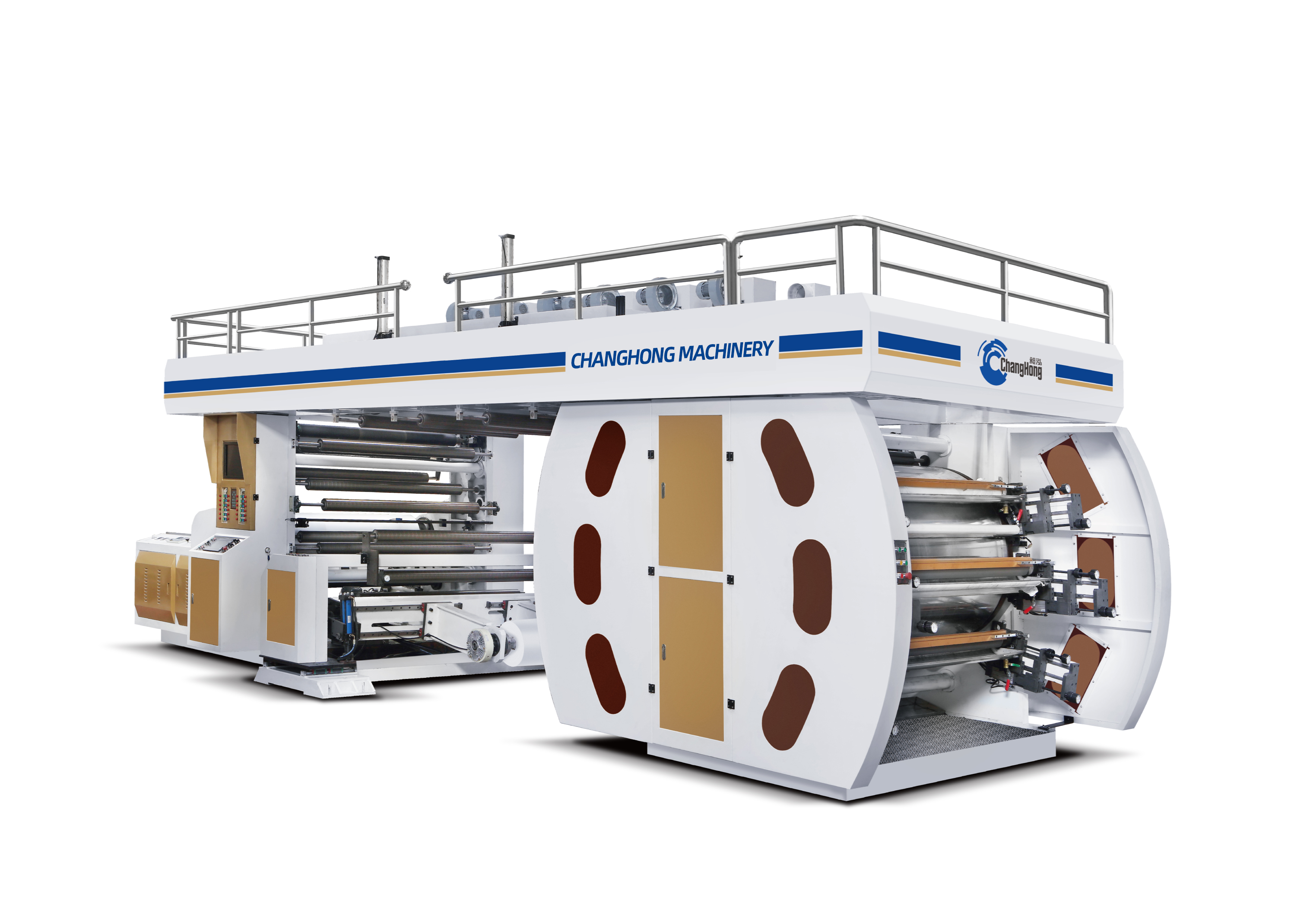

Low MOQ for Roll to Roll High Speed stack Flexo Printing Machine for BOPP PE PP LDPE

Low MOQ for Roll to Roll High Speed stack Flexo Printing Machine for BOPP PE PP LDPE

We not only will try our greatest to supply excellent solutions to just about every consumer, but also are ready to receive any suggestion offered by our consumers for Low MOQ for Roll to Roll High Speed stack Flexo Printing Machine for BOPP PE PP LDPE, Leading the trend of this field is our persistent objective. Supplying 1st class products and solutions is our intention. To make a beautiful long term, we would want to cooperate with all friends at your house and abroad. Should you’ve any interest within our products, remember to usually do not be reluctant to get in touch with us.

We not only will try our greatest to supply excellent solutions to just about every consumer, but also are ready to receive any suggestion offered by our consumers for stack Flexographic Printing Press and Flexographic Printing Machine 8 color, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Technical Specifications

| Model | CH8-600B-S | CH8-800B-S | CH8-1000B-S | CH8-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ600mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video introduction

Machine Features

1. stack flexo press can achieve the effect of double-sided printing in advance, and can also perform multi-color and single-color printing.

2. The stacked flexo printing machine is advanced and can help users automatically control the system of the printing machine itself by setting tension and registration.

3. Stacked flexo printing presses can print on a variety of plastic materials, even in roll form.

4. Because flexographic printing uses anilox rollers to transfer ink, ink will not fly during high-speed printing.

5. Independent drying system, using electric heating and adjustable temperature.

Details Dispaly

Options

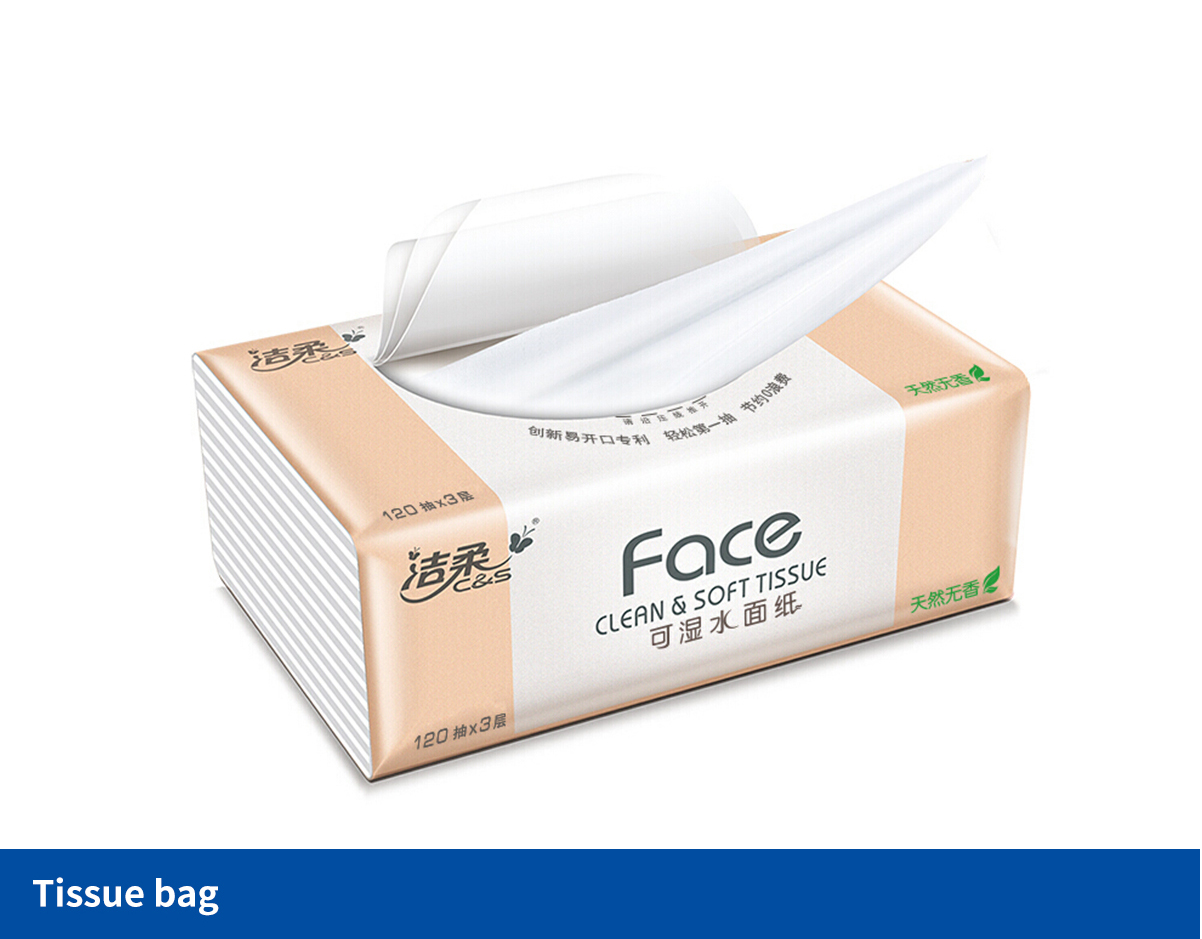

Sample

We not only will try our greatest to supply excellent solutions to just about every consumer, but also are ready to receive any suggestion offered by our consumers for Low MOQ for Roll to Roll High Speed stack Flexo Printing Machine for BOPP PE PP LDPE, Leading the trend of this field is our persistent objective. Supplying 1st class products and solutions is our intention. To make a beautiful long term, we would want to cooperate with all friends at your house and abroad. Should you’ve any interest within our products, remember to usually do not be reluctant to get in touch with us.

Low MOQ for stack Flexographic Printing Press and Flexographic Printing Machine 8 color, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.