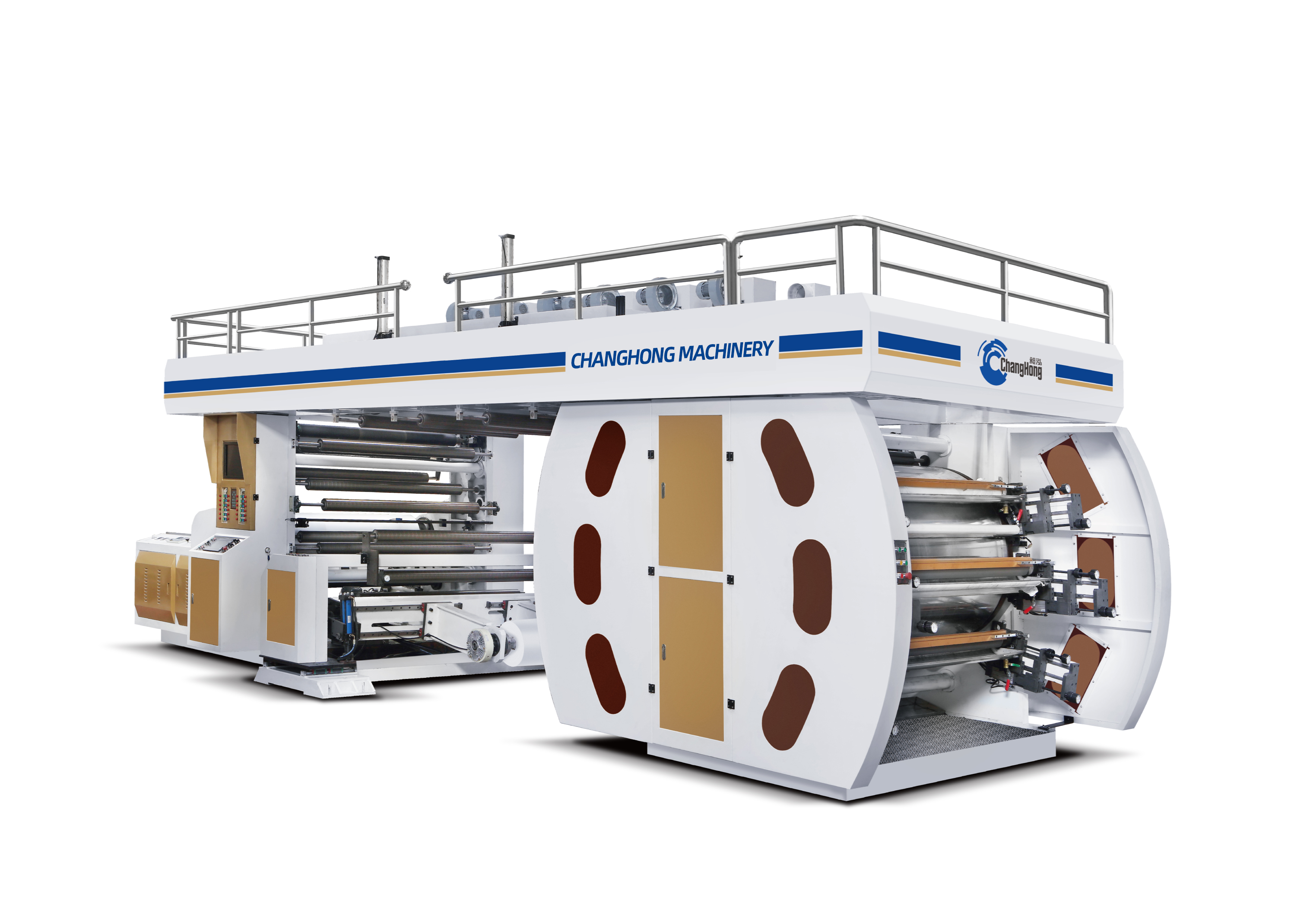

ODM Supplier CHCI-E-S Sleeve Type CI Flexo Graphic Printing Machine for LDPE/CPP/HDPE/OPP/BOPP plastic films

ODM Supplier CHCI-E-S Sleeve Type CI Flexo Graphic Printing Machine for LDPE/CPP/HDPE/OPP/BOPP plastic films

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for ODM Supplier CHCI-E-S Sleeve Type CI Flexo Graphic Printing Machine for LDPE/CPP/HDPE/OPP/BOPP plastic films, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for business cooperation.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for 4 6 8 Color Flexo Printing Machine and Automatic CI Printing Machine, We always insist on the management tenet of “Quality is First, Technology is Basis, Honesty and Innovation”.We’re able to develop new solutions continuously to a higher level to satisfy different needs of customers.

technical specifications

|

Model |

CHCI6-600E-S |

CHCI6-800E-S |

CHCI6-1000E-S |

CHCI6-1200E-S |

|

Max. Web Width |

700mm |

900mm |

1100mm |

1300mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

350m/min |

|||

|

Max. Printing Speed |

300m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1000mm/Φ1200mm |

|||

|

Drive Type |

Central drum with Gear drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Video Introduction

Machine Features

1.The CI flexo press features a Sleeve Type side-sleeve structure, allowing plate installation/replacement without roller disassembly. It greatly simplifies operations, cuts plate change time, and adapts to different printing widths—suiting small-batch customization and large-batch production.

2.The CI flexo printing press uses a sturdy central impression cylinder, ensuring constant tension for PP/PE/CPP/BOPP films during printing. It minimizes material stretch/deformation, delivering excellent registration accuracy and perfect complex pattern reproduction.

3. Our central impression flexo press comes equipped with a high-precision, fully automatic BST Video inspection system. This system scans, monitors, and records printed patterns in real time, helping to avoid large-scale quality issues and improve the overall pass rate.

4. The CI flexographic printer features an advanced central control system that integrates precise monitoring and adjustment of key parameters, including tension, registration, and temperature. Its intuitive, easy-to-use Control Panel lessens the need for extensive operator experience, ensuring stable production and consistent quality control.

5. For thin-film flexible packaging—particularly food-grade applications, it has optimized ink circulation and drying systems. It supports eco-friendly inks, such as water-based options, and is equipped with a Heating and Drying Unit to speed up ink setting. At the same time, it keeps solvent residues in check to comply with strict food packaging standards.

Details Dispaly

Printing Samples

Our CI flexo printing press is specifically optimized for the surface properties of flexible packaging films like PP, PE, CPP, and BOPP. This ensures strong ink adhesion and excellent drying performance, supporting a wide range of printing needs. It’s an ideal solution for flexible packaging applications in food, daily chemicals, and pharmaceuticals.

Packaging And Delivery

The ci flexo printing machine you ordered is protected every step of the way—from our factory straight to your workshop. The entire delivery process is fully transparent and trackable, with real-time logistics updates provided throughout.

Once the equipment arrives at your facility, we’ll assist with coordinating unloading and handling, walk you through the initial inspection, and put you in direct touch with our technical team to schedule installation and commissioning. This way, you can receive your equipment with complete peace of mind and quickly get started with production.

FAQ

Q: What’s the machine’s production lead time?

A: It depends on the order situation and machine configuration. We will confirm the specific lead time with you after receiving your inquiry.

Q: Can the machine be customized?

A: Yes. We can customize key configurations according to your actual production needs. Please contact us for specific customization requirements.

Q: What payment terms do you accept?

A: We accept common international payment terms such as T/T and L/C.

Q: Do you offer operation training?

A: Yes. We provide operation and maintenance training during the on-site installation by our engineer, to help your team get familiar with the machine.

Q: What about the after-sales service?

A: – Within 1 year of purchase: Free replacement of wearing parts, and free support ( online consultation & video guidance) for machine faults.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for ODM Supplier CHCI-E-S Sleeve Type CI Flexo Graphic Printing Machine for LDPE/CPP/HDPE/OPP/BOPP plastic films, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for business cooperation.

ODM Supplier 4 6 8 Color Flexo Printing Machine and Automatic CI Printing Machine, We always insist on the management tenet of “Quality is First, Technology is Basis, Honesty and Innovation”.We’re able to develop new solutions continuously to a higher level to satisfy different needs of customers.