OEM China PP Woven Bag plastic films Ci Flexographic Printing Machine for LDPE/CPP/PE/OPP

OEM China PP Woven Bag plastic films Ci Flexographic Printing Machine for LDPE/CPP/PE/OPP

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for OEM China PP Woven Bag plastic films Ci Flexographic Printing Machine for LDPE/CPP/PE/OPP, We’ve been expecting to cooperate along with you on the basis of mutual advantages and common advancement. We’re going to never disappoint you.

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for ci Flexo Printing Machine and PP Woven plastic Flexographic Printing Machine, We always hold on the company’s principle “honest, experienced, effective and innovation”, and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We’re determined to become the integrator of our product market and one-stop service provider of our product market.

technical specifications

| Model | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

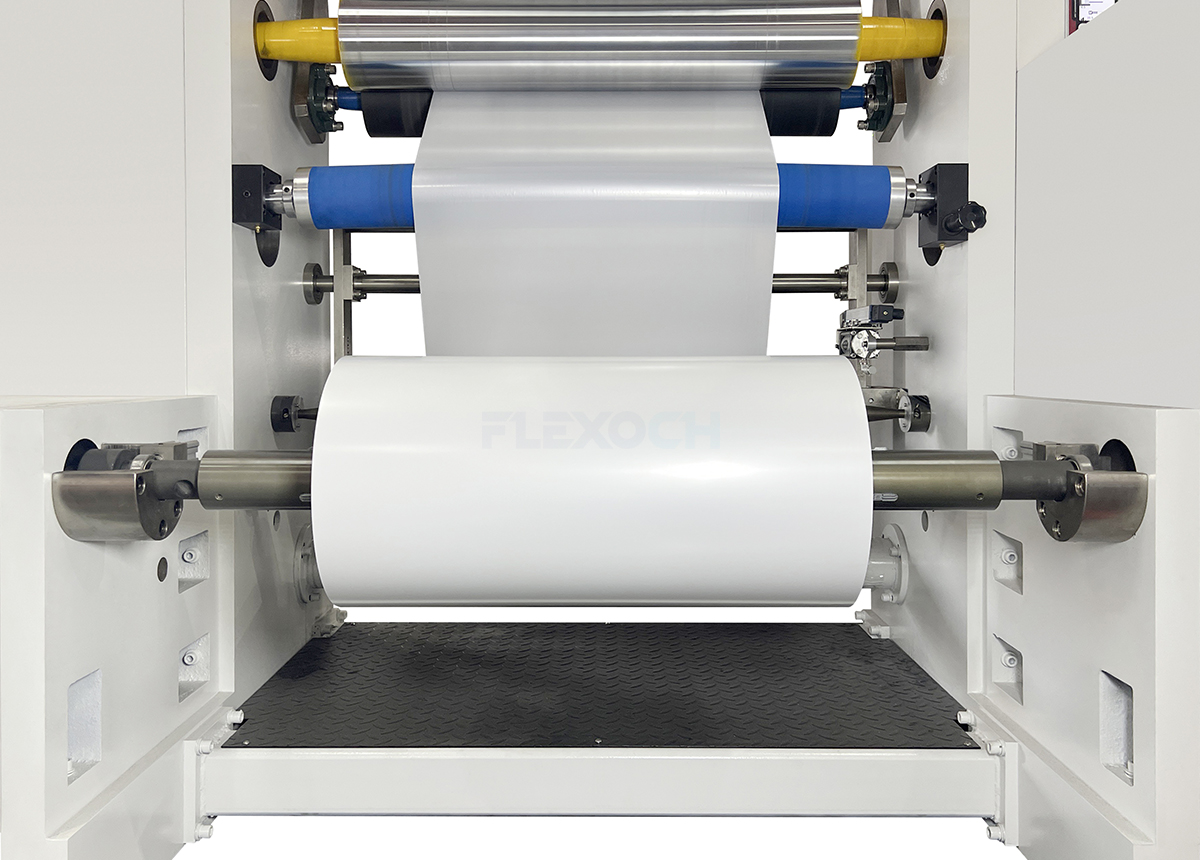

● Central Impression (CI) technology:The ci flexo printing machine adopts an integrated central impression cylinder design to ensure that the 6 color printing registration accuracy is ≤±0.1mm. Even at high speed (up to 300m/min), it can achieve flawless pattern transition, meeting the high requirements for color levels in food packaging, daily chemical labels, etc.

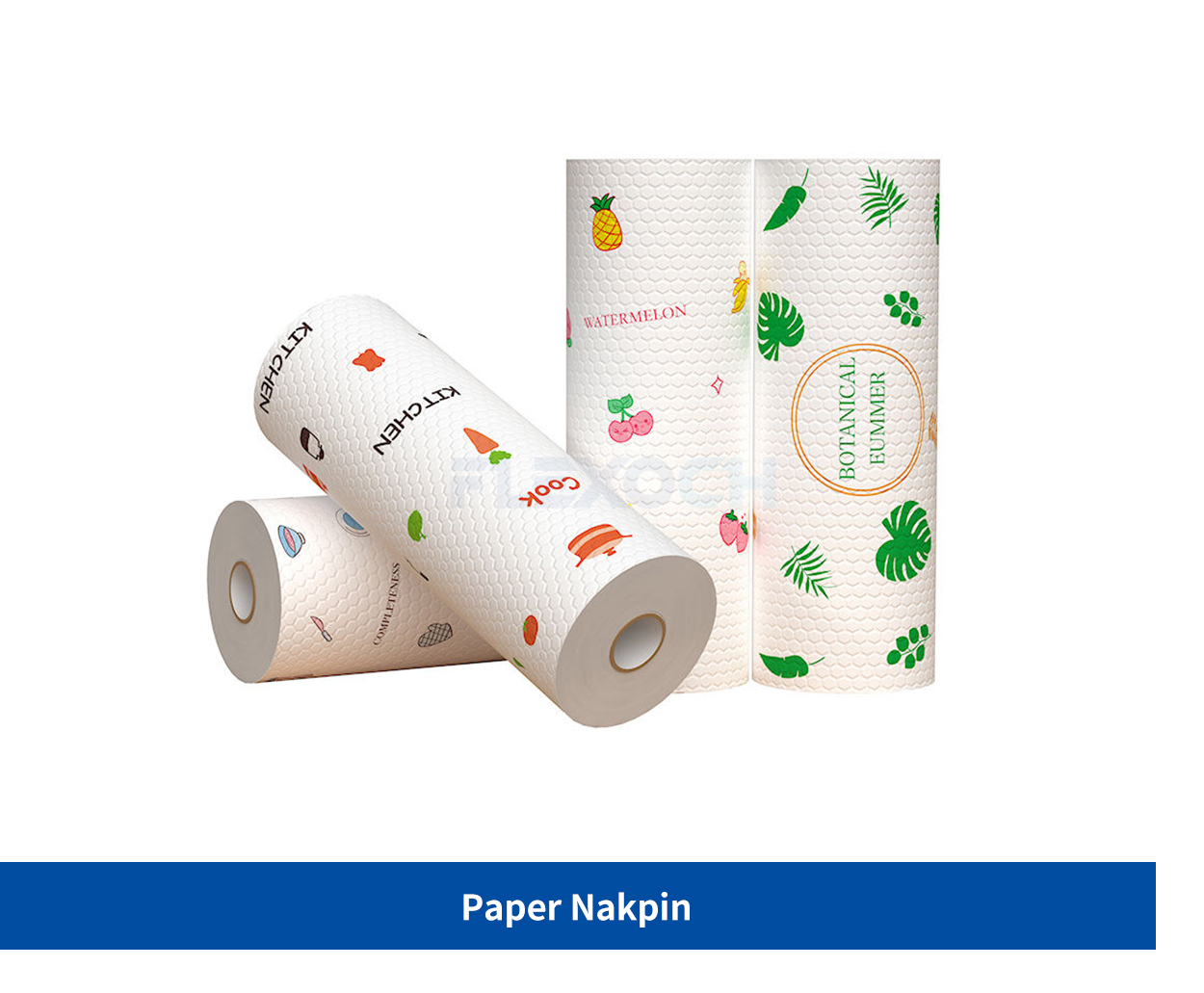

● Full material compatibility: The ci flexo printing machine is suitable for a variety of film substrates and various materials, and can easily cope with the diversified production needs of flexible packaging bags, shrink films, labels, etc.

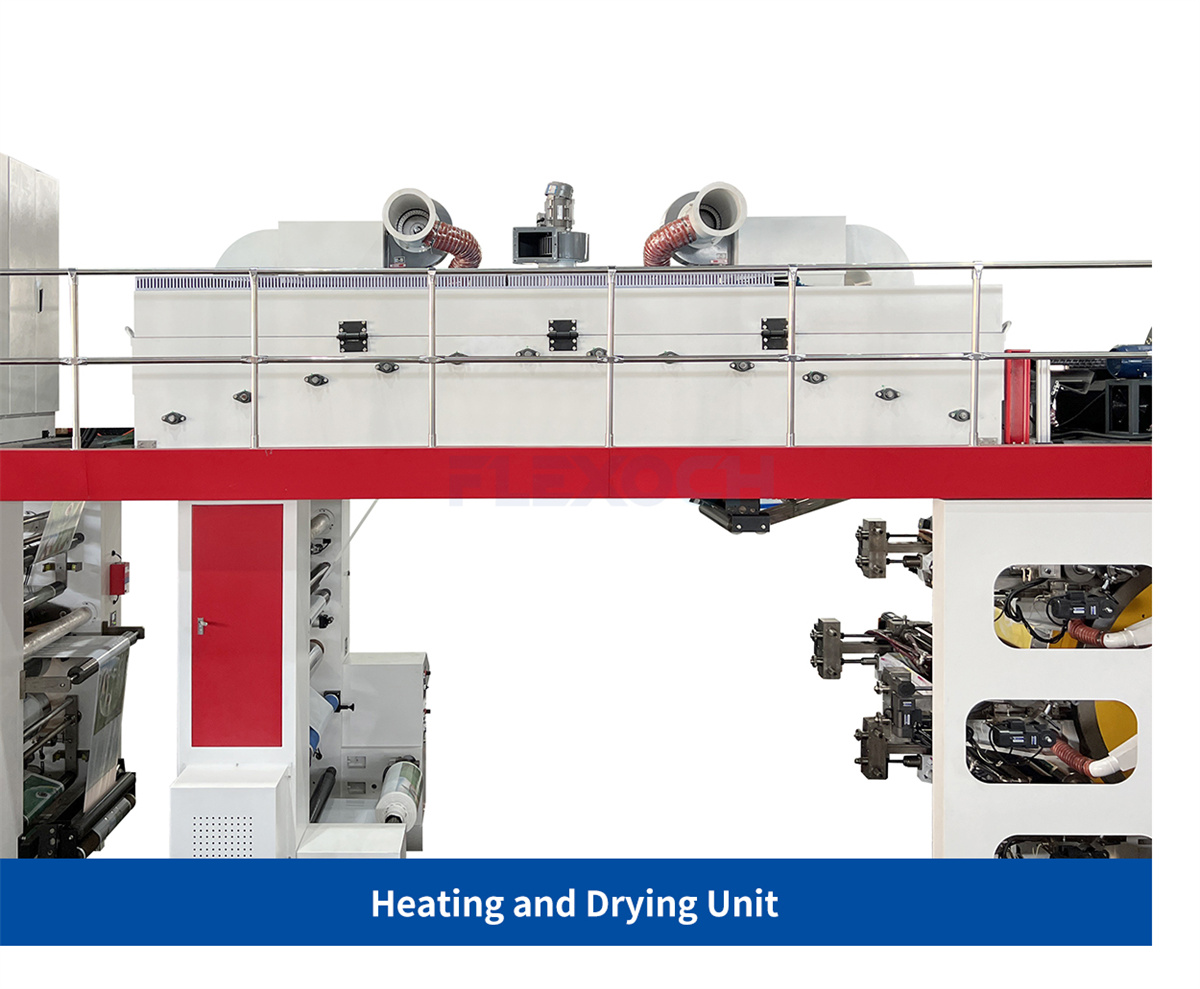

● Environmentally friendly and efficient printing: The flexo printing press supports water-based inks and UV-curing inks, and VOC emissions are far lower than industry standards. Combined with an intelligent drying system, it balances environmental responsibility and economic benefits to achieve sustainable high production.

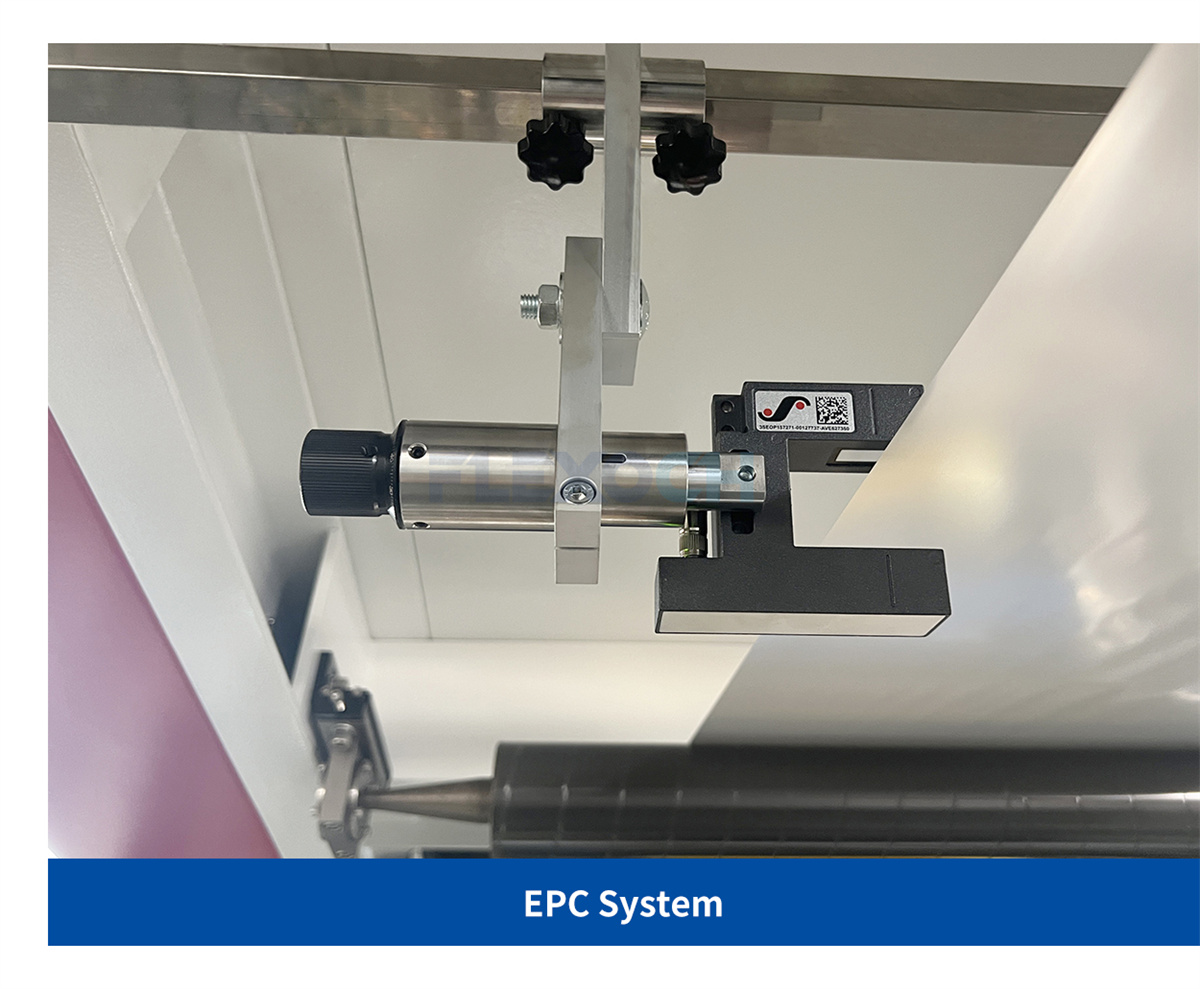

● Intelligent operation experience: The central drum flexo printing machine adopts a full touch screen PLC control system, one-button preset parameters, and fast plate change (≤15 minutes); closed-loop tension control to prevent film wrinkling and stretching deformation.

Details Dispaly

sample

Packaging and Delivery

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for OEM China PP Woven Bag plastic films Ci Flexographic Printing Machine for LDPE/CPP/PE/OPP, We’ve been expecting to cooperate along with you on the basis of mutual advantages and common advancement. We’re going to never disappoint you.

OEM China ci Flexo Printing Machine and PP Woven plastic Flexographic Printing Machine, We always hold on the company’s principle “honest, experienced, effective and innovation”, and missions of: let all drivers enjoy their driving at night, let our employees can realize their value of life, and to be stronger and service more people. We’re determined to become the integrator of our product market and one-stop service provider of our product market.