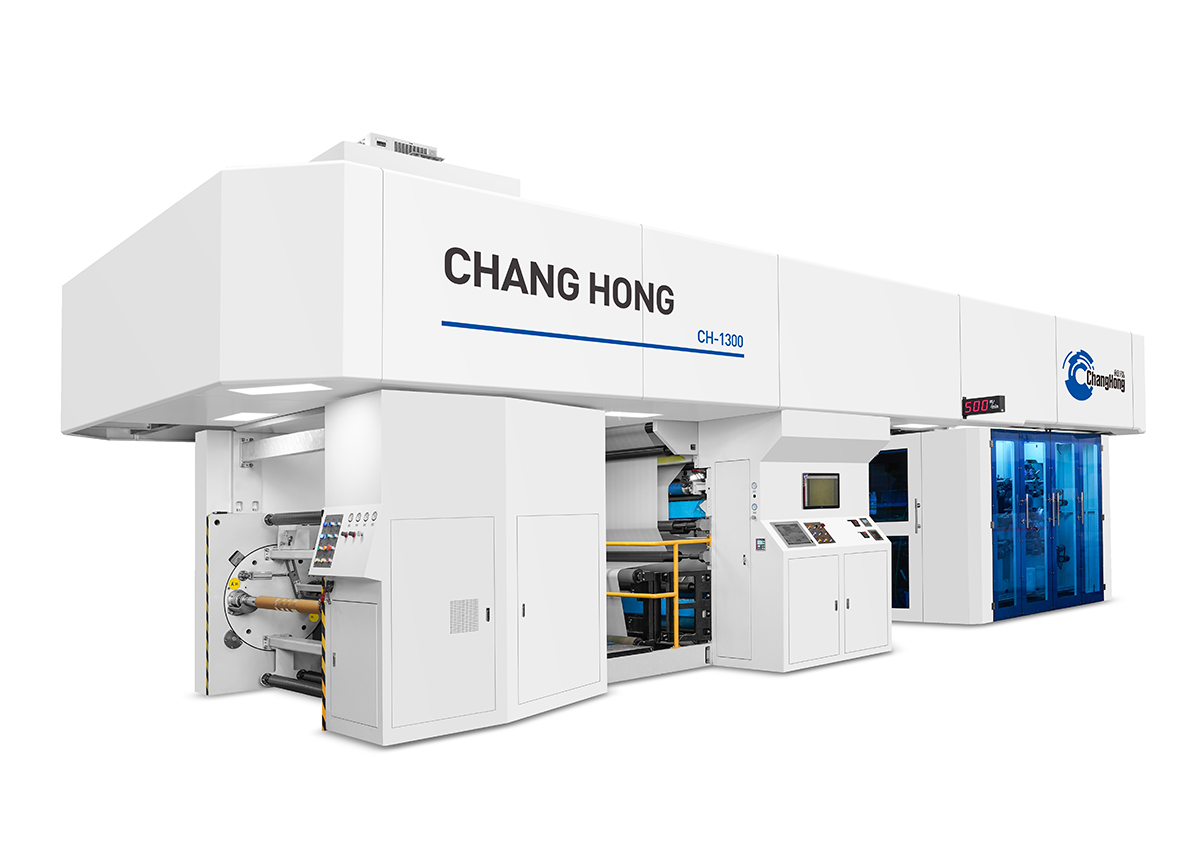

OEM Customized Automatic stack type Flexo printing Machinery for plastic films LDPE/CPP/OPP

OEM Customized Automatic stack type Flexo printing Machinery for plastic films LDPE/CPP/OPP

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for OEM Customized Automatic stack type Flexo printing Machinery for plastic films LDPE/CPP/OPP, We focus on for making great high quality products to offer services for our consumers to establish long-term win-win romance.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Flexo Printing Machine and Flexographic Printing Machine, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable goods quality , increase customers’ satisfaction and achieve win-win situation .

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max.Unwind/Rewind Dia. | Φ600mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High production capacity: The three-unwinder, three-rewinder stacked flexo press has a fast printing speed and high output, allowing large quantities of labels and packaging to be produced in a short time.

2. Registration accuracy: The registration system of this press is highly accurate, ensuring superior print quality and perfect alignment of designs.

3. Flexibility: The three-unwinder, three-rewinder stacked flexo press can handle a wide variety of substrates, such as paper, cardboard, plastic film, and other materials, making it perfect for printing different products.

4. Easy operation: The machinery features a simple and intuitive control system, making it easy to use and reducing human error.

5. Low maintenance: The stacked flexo press with three unwinders and three rewinders has a robust and high-quality design that requires little maintenance and has a long service life.

Details Dispaly

sample

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for OEM Customized Automatic stack type Flexo printing Machinery for plastic films LDPE/CPP/OPP, We focus on for making great high quality products to offer services for our consumers to establish long-term win-win romance.

OEM Customized Flexo Printing Machine and flexographic Printing Machine, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable goods quality , increase customers’ satisfaction and achieve win-win situation .