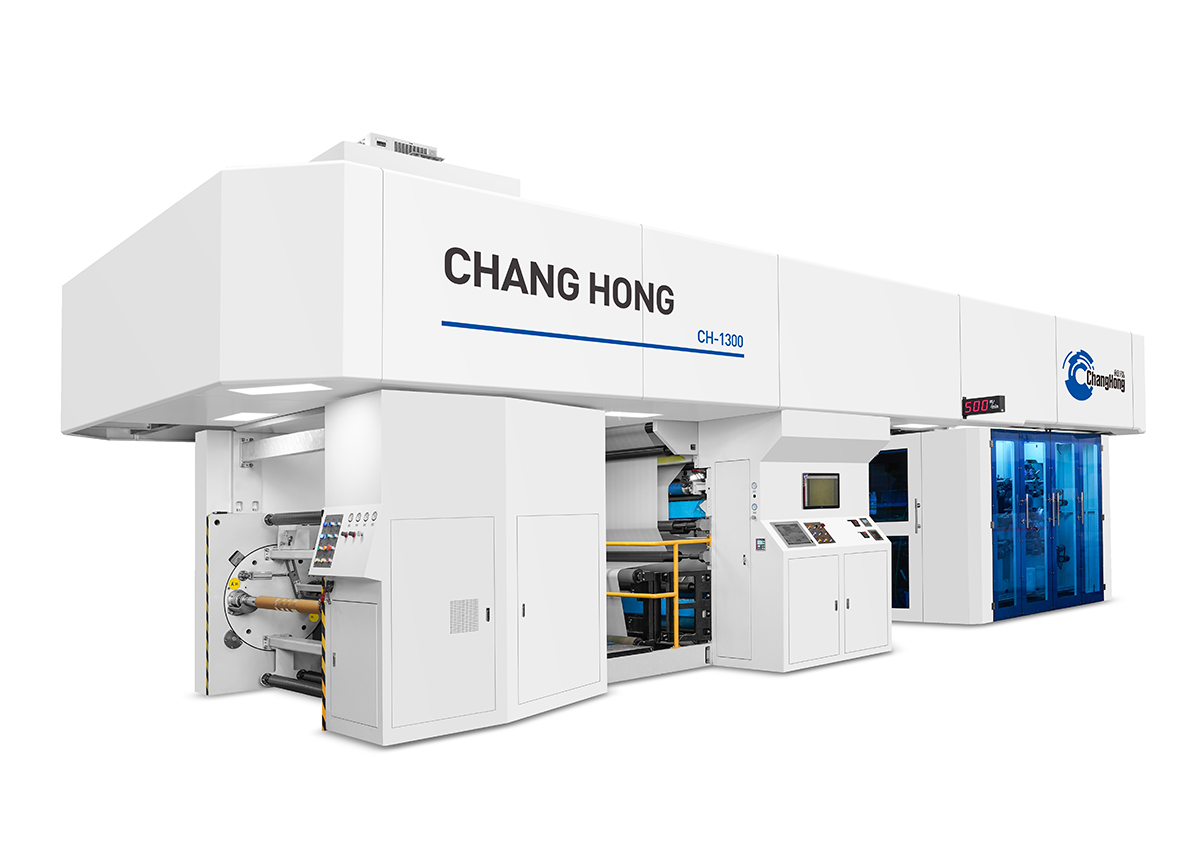

OEM Manufacturer Food Package Paper Cup Paper Bag Centrel Drum Flexo Printing Machine Ci Type Flexographic Printing Press

OEM Manufacturer Food Package Paper Cup Paper Bag Centrel Drum Flexo Printing Machine Ci Type Flexographic Printing Press

We persist with our business spirit of “Quality, Effectiveness, Innovation and Integrity”. We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for OEM Manufacturer Food Package Paper Cup Paper Bag Centrel Drum Flexo Printing Machine Ci Type Flexographic Printing Press, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

We persist with our business spirit of “Quality, Effectiveness, Innovation and Integrity”. We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for Flexo Printing Machine and Ci Flexo Printing Machine, Strong infrastructure is the have to have of any organization. We’re backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’ve been able to accomplish voluminous production without compromising on the quality.

technical specifications

| Model | CHCI4-600J-S | CHCI4-800J-S | CHCI4-1000J-S | CHCI4-1200J-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

Machine Features

● Precision CI Flexo Press Design:The ci flexo press ensures excellent register accuracy (±0.1mm) with automatic web tension control throughout the printing process. Its optimized vibration-dampening structure maintains consistent print quality at production speeds up to 200m/min for extended operation.

● Multi-Substrate Compatibility for Flexo Press:Specially designed ink stations and adjustable tension system make this flexo printing machine ideal for various materials including plastic films (10-150μm), non-woven fabrics and papers while maintaining optimal print clarity.

● Efficient Drying System in Flexographic Press:The integrated heating and drying unit in this CI flexo press provides adjustable temperature control to ensure proper ink setting, enabling immediate downstream processing without smudging across the web width.

● Intelligent Operation of Flexographic Printing Press:The intuitive control panel of this flexographic printing machine features preset job memory and real-time monitoring functions, significantly reducing setup time and improving production efficiency.

Details Dispaly

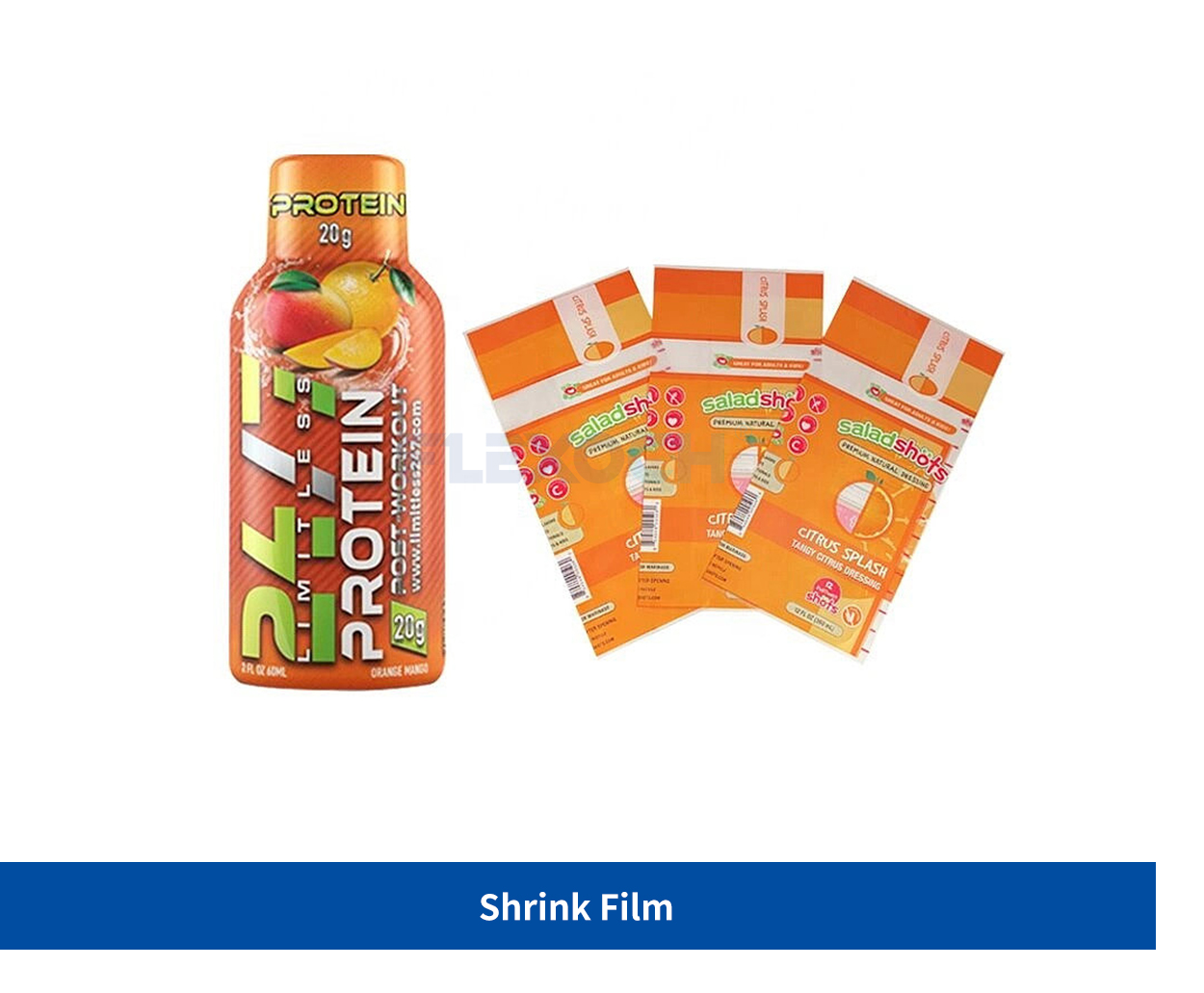

sample

Packaging and Delivery

We persist with our business spirit of “Quality, Effectiveness, Innovation and Integrity”. We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for OEM Manufacturer Food Package Paper Cup Paper Bag Centrel Drum Flexo Printing Machine Ci Type Flexographic Printing Press, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

OEM Manufacturer Flexo Printing Machine and Ci Flexo Printing Machine, Strong infrastructure is the have to have of any organization. We’re backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’ve been able to accomplish voluminous production without compromising on the quality.