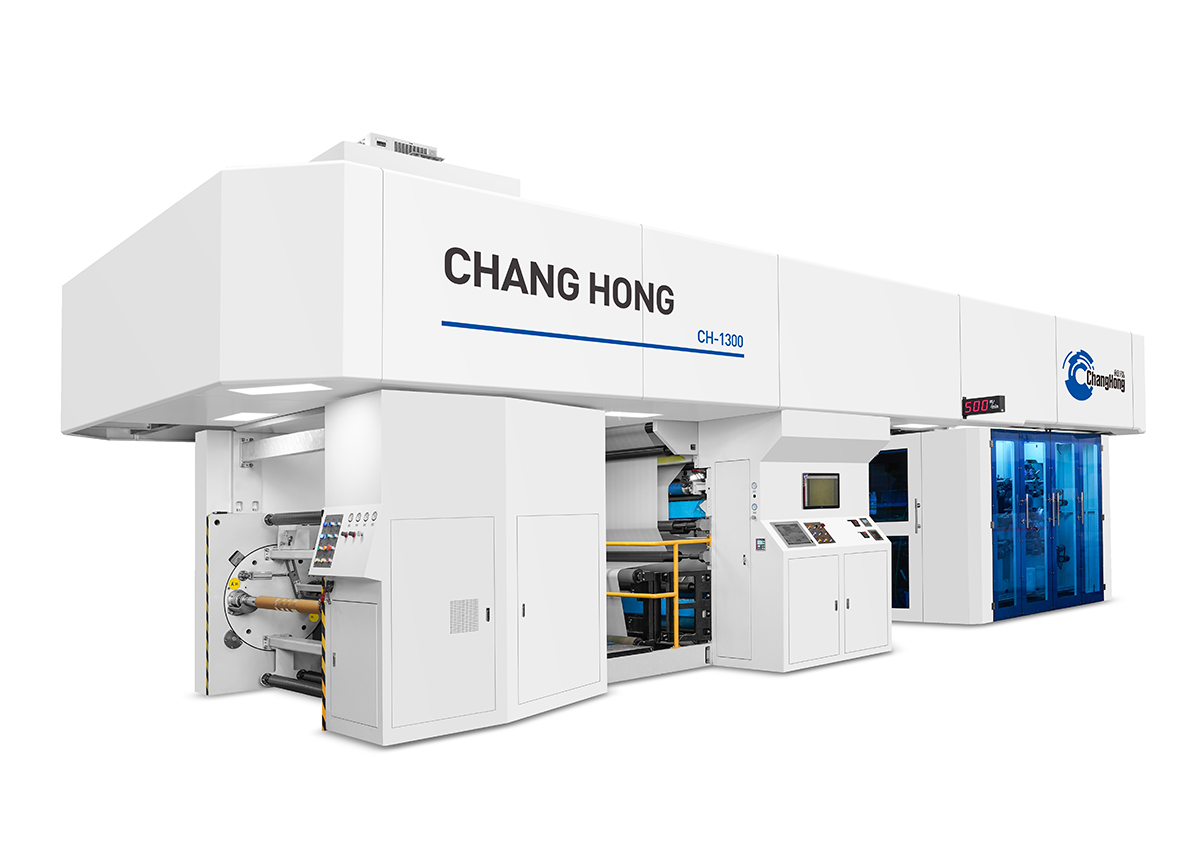

OEM Manufacturer Machine Speed 120 m/min Four Color Flexo Printing Machine for LDPE/CPP/BOPP/PE

OEM Manufacturer Machine Speed 120 m/min Four Color Flexo Printing Machine for LDPE/CPP/BOPP/PE

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for OEM Manufacturer Machine Speed 120 m/min Four Color Flexo Printing Machine for LDPE/CPP/BOPP/PE, We are keeping durable small business relationships with additional than 200 wholesalers in the USA, the UK, Germany and Canada. For anyone who is intrigued in any of our products, make sure you experience free to speak to us.

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for Stack Type Flexo Printing Machine 4 Color and Flexo Printing Presses, They’re durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it’s a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we’ll have a vibrant prospect and to be distributed all over the world in the years to come.

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

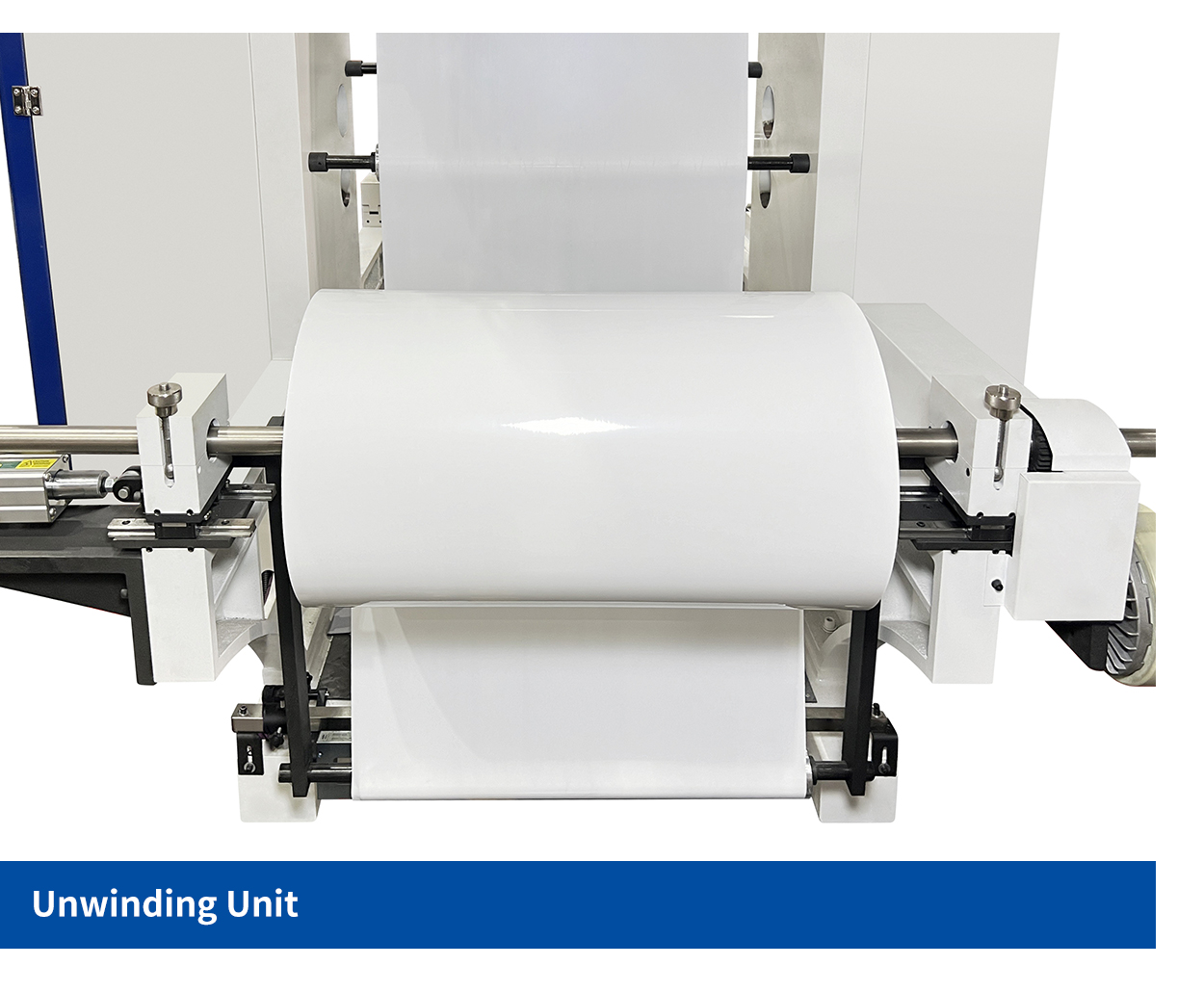

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

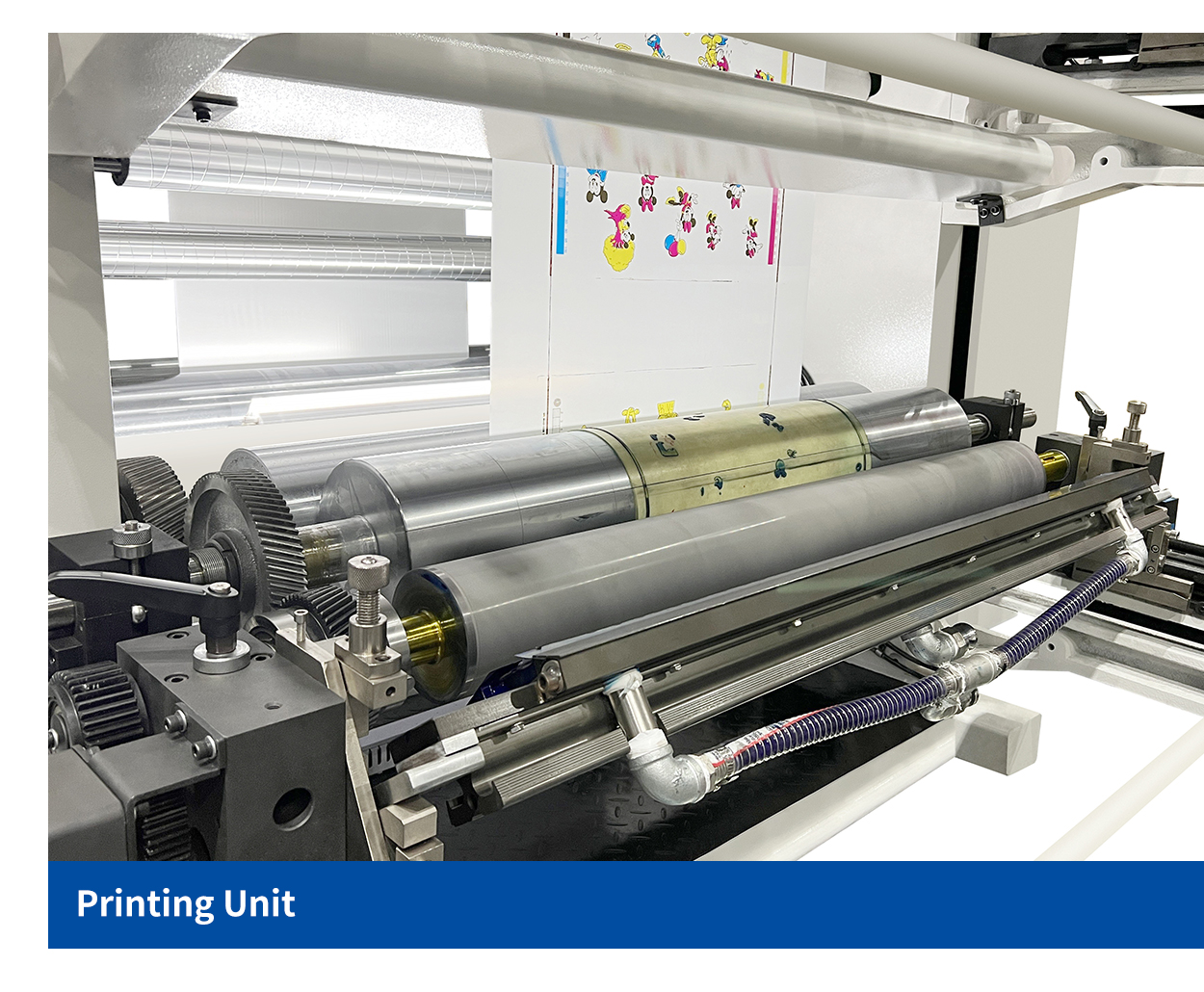

● The corona treatment stack flexographic printing machine is an advanced technology used in the printing industry to produce a wide range of high-quality products such as paper bags, labels, food packaging, medicine packaging and much more.

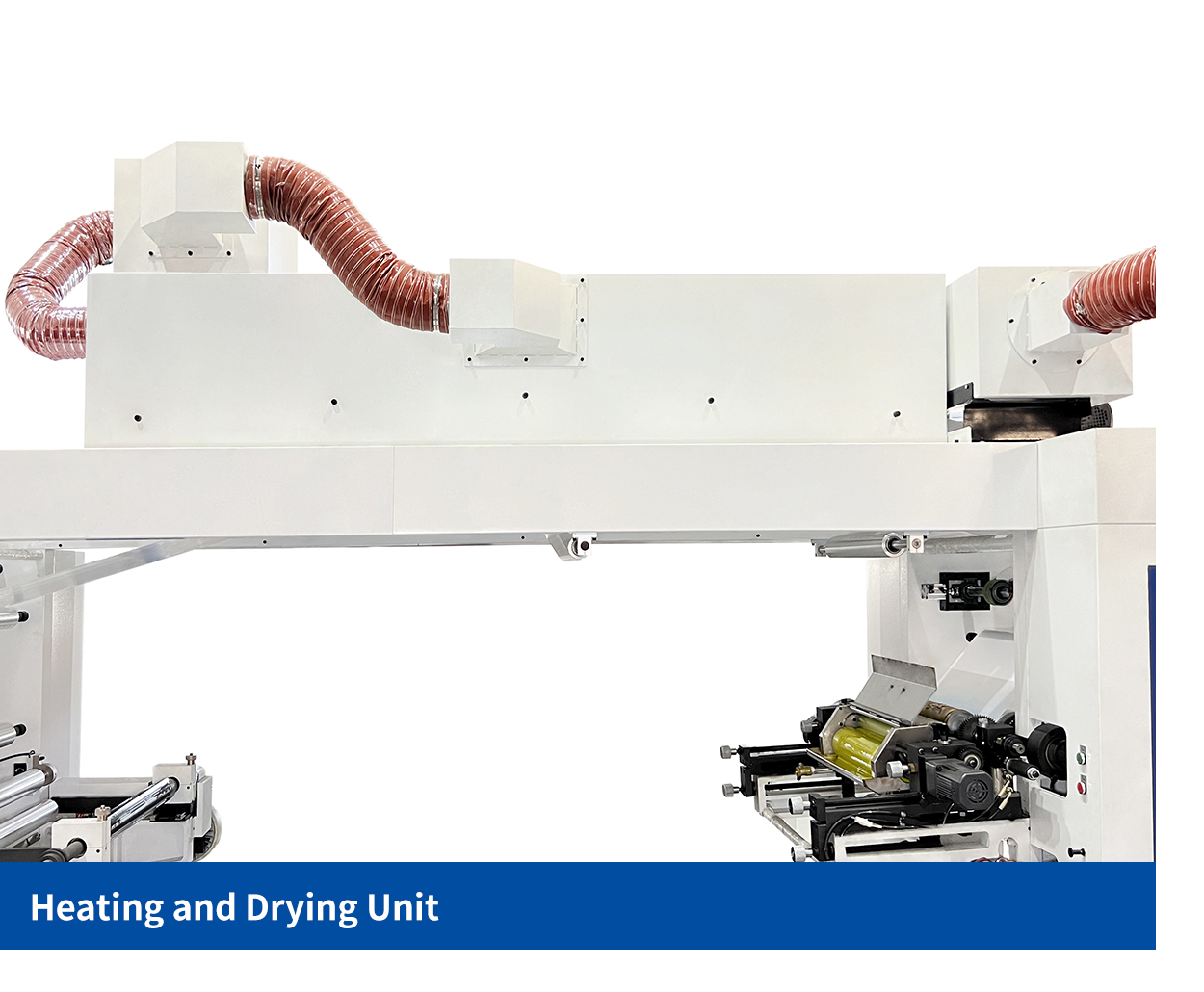

● The main advantage of this machine is the ability to treat the surface of the printing material with corona. This means that a significant improvement in print quality occurs. Corona is a surface treatment technology used to increase the surface energy of the surface of printing materials, allowing inks and adhesives to better adhere to the surface of the substrate.

● Another important advantage of this machine is its flexibility. It can print on a wide variety of materials, from paper to plastic, and on a wide range of products of different sizes and shapes. In addition, it can be used in a wide variety of applications, from labels to high-quality packaging.

● In addition to producing high-quality prints, the corona treatment stack flexographic printing machine can also be used to produce high-speed prints. This is because prints can be produced at high speed, meaning that large quantities of products can be produced in a short time.

Details Dispaly

sample

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for OEM Manufacturer Machine Speed 120 m/min Four Color Flexo Printing Machine for LDPE/CPP/BOPP/PE, We are keeping durable small business relationships with additional than 200 wholesalers in the USA, the UK, Germany and Canada. For anyone who is intrigued in any of our products, make sure you experience free to speak to us.

OEM Manufacturer Stack Type Flexo Printing Machine 4 Color and Flexo Printing Presses, They’re durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it’s a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we’ll have a vibrant prospect and to be distributed all over the world in the years to come.