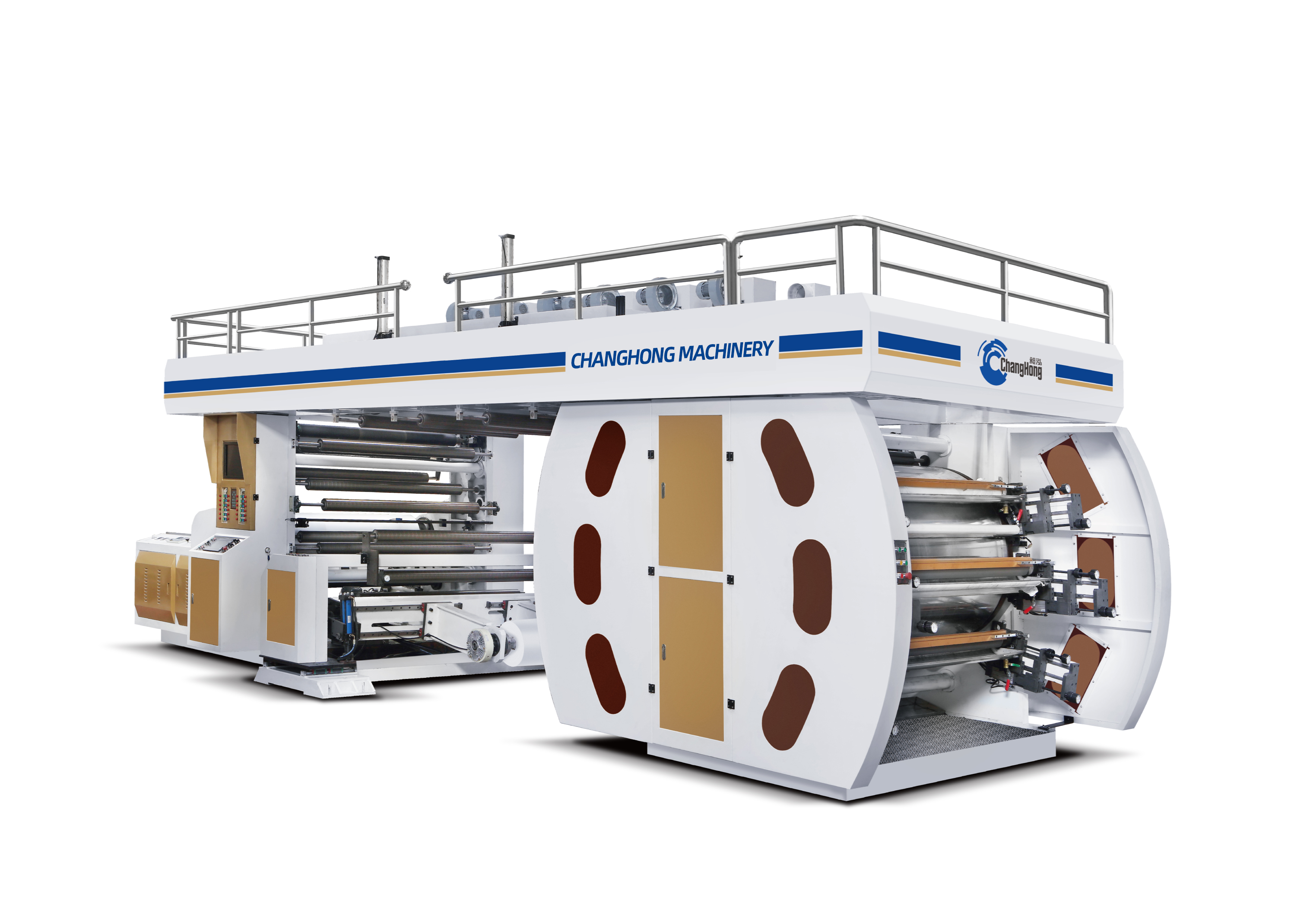

OEM Supply 4/6/8 Colors Central Drum Flexographic Printing Machine for BOPP/PE/Pet/OPP

OEM Supply 4/6/8 Colors Central Drum Flexographic Printing Machine for BOPP/PE/Pet/OPP

It truly is our accountability to meet your needs and proficiently provide you. Your pleasure is our best reward. We are on the lookout ahead to the stop by for joint development for OEM Supply 4/6/8 Colors Central Drum Flexographic Printing Machine for BOPP/PE/Pet/OPP, We will continually strive to improve our service and provide the best quality products with competitive prices. Any inquiry or comment is highly appreciated. Please contact us freely.

It truly is our accountability to meet your needs and proficiently provide you. Your pleasure is our best reward. We are on the lookout ahead to the stop by for joint development for Flexo Printing Machine and stack Flexo Printing Machine, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to give our best service to satisfy all your needs! Remember to contact us right away!

technical specifications

| Model | CH4-600B-NW | CH4-800B-NW | CH4-1000B-NW | CH4-1200B-NW |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High Precision Printing: equipped with advanced technology and high-quality components, which help in achieving accurate and vibrant printing on woven bags.

2. Variable printing speed: The printing speed of the machine can be adjusted according to the printing requirements, which offers greater flexibility during the printing process.

3. High production capacity: PP woven bag flexo printing machines have a high production capacity, enabling the printing of large quantities of woven bags in a shorter time span.

4.Low wastage: The PP woven bag Stack flexo printing machine consumes less ink and produces less wastage.

5.Environmentally friendly: PP woven bag stack flexo printing machines use water-based inks and produce minimal waste, making them eco-friendly.

Details Dispaly

sample

Packaging and Delivery

FAQ

Q:What are the features of a PP woven bag stack flexo printing machine?

A:The features of a PP woven bag stack flexo printing machine typically include an advanced PLC control system, servo motor control, automatic tension control, automatic register system, and more. These features ensure high precision and quality printing.

Q: How does a PP woven bag stack flexo printing machine print on bags?

A:A PP woven bag stack flexo printing machine uses specialized ink and a printing plate to transfer the desired image or text onto the PP woven bags. The bags are loaded onto the machine and fed through rollers to ensure the ink is evenly applied.

Q: What maintenance is required for a PP woven bag stack flexo printing machine?

A:Maintenance requirements for a PP woven bag stack flexo printing machine typically include regular cleaning and lubrication of moving parts, as well as periodic replacement of wear and tear components, such as printing plates and ink rollers.

It truly is our accountability to meet your needs and proficiently provide you. Your pleasure is our best reward. We are on the lookout ahead to the stop by for joint development for OEM Supply 4/6/8 Colors Central Drum Flexographic Printing Machine for BOPP/PE/Pet/OPP, We will continually strive to improve our service and provide the best quality products with competitive prices. Any inquiry or comment is highly appreciated. Please contact us freely.

OEM Supply Flexo Printing Machine and stack Flexo Printing Machine, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to give our best service to satisfy all your needs! Remember to contact us right away!