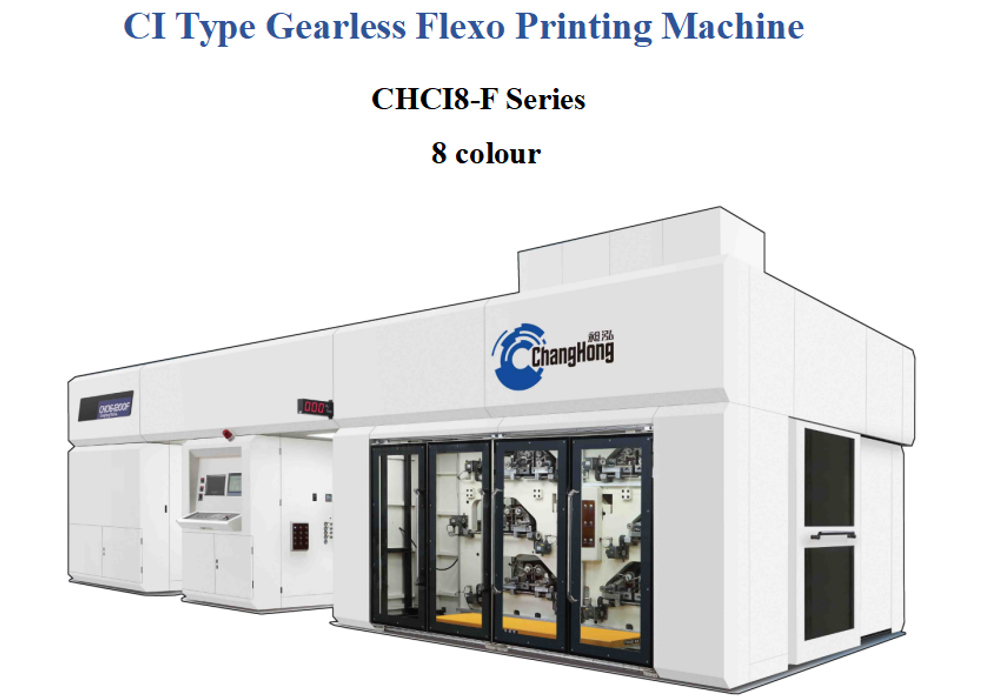

OEM/ODM China Ci Flexo Printing Machine For Pp Woven - High speed 8 colour gearless CI flexo printing machine – Changhong

OEM/ODM China Ci Flexo Printing Machine For Pp Woven - High speed 8 colour gearless CI flexo printing machine – Changhong

OEM/ODM China Ci Flexo Printing Machine For Pp Woven - High speed 8 colour gearless CI flexo printing machine – Changhong Detail:

technical specifications

| Model | CHCI8-600F | CHCI8-800F | CHCI8-1000F | CHCI8-1200F |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-800mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon,PAPER,NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Function Description

- Double station unwinding

- Full servo Printing system

- Pre registration function

- Production menu memory function

- Start up and shut down automatic clutch pressure function

- Automatic pressure adjustment function in the process of printing speed up

- Chamber doctor blade quantitative ink supply system

- temperature control and centralized drying after printing

- EPC before printing

- It has cooling function after printing

- Double station winding.

Double Station Turret Unwinding

Tension control: Using ultra-light floating roller control, automatic tension compensation, closed loop control (low friction cylinder position Detection, precise pressure regulating valve control, automatic alarm or shutdown when the roll diameter reaches the set value)

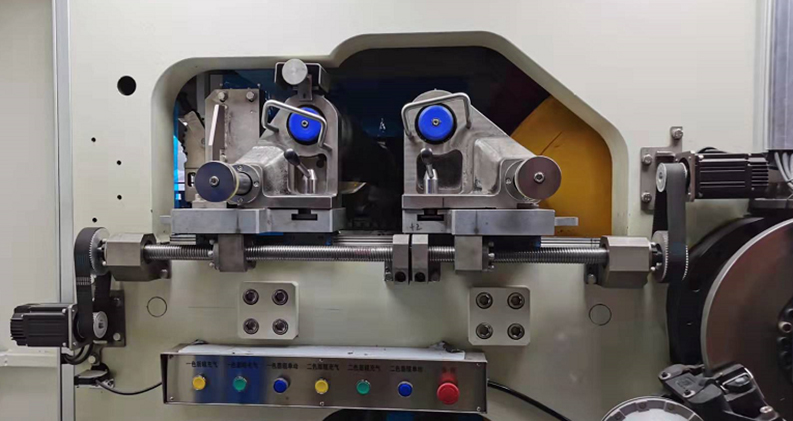

Pressure regulation

The pressure between the anilox roller and the printing plate roller is driven by 2 servo motors for each color, and the pressure is adjusted by ball screws and upper and lower double linear guides, with position memory function

Doctor blade and ink supply system

Aluminum alloy profile doctor blade cavity, seal ink, reduce solvent volatilization, keep ink viscosity and clean.

Sleeve Syetem

Printing Cylinder sleeve imported from Europe

Sleeve ceramic anilox roller

Central drying system

Intelligent continuous constant temperature control, fully enclosed structure, air box adopts heat preservation structure.

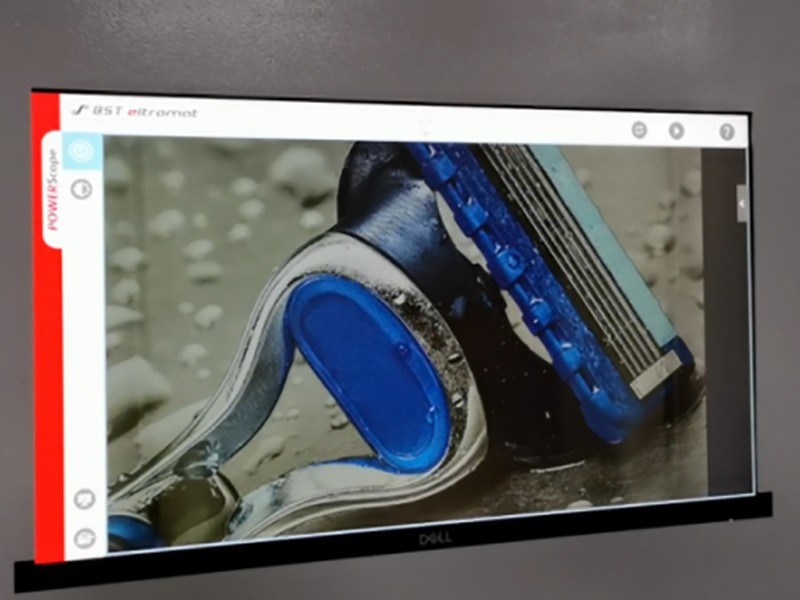

Video Inspection System

Double Station Turret Rewinding

Printing Sample

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for OEM/ODM China Ci Flexo Printing Machine For Pp Woven - High speed 8 colour gearless CI flexo printing machine – Changhong , The product will supply to all over the world, such as: Oman, Toronto, Guinea, Our technical expertise, customer-friendly service, and specialized merchandise make us/company name the first choice of customers and vendors. We've been looking for your inquiry. Let's set up the cooperation right now!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!