OEM/ODM Manufacturer Stack Type Plastic Flexo Printing Machine 4 6 8 Colors

OEM/ODM Manufacturer Stack Type Plastic Flexo Printing Machine 4 6 8 Colors

We insist to the theory of development of ‘High excellent, Performance, Sincerity and Down-to-earth working approach’ to deliver you with great provider of processing for OEM/ODM Manufacturer Stack Type Plastic Flexo Printing Machine 4 6 8 Colors, We can do your custom-made get to fulfill your own satisfactory! Our company sets up several departments, including output department, revenue department, excellent control department and sevice center, etc.

We insist to the theory of development of ‘High excellent, Performance, Sincerity and Down-to-earth working approach’ to deliver you with great provider of processing for 4 Color Flexography Printing Machine and Flexography Printing Machine, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So remember to feel free to contact us for inquiries. You’ll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely supply you with the best quotation and after-sale service. We’re ready to build stable and friendly relations with our merchants. To achieve mutual success, we’ll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we’re here to welcome your inquiries for any of our items and service.

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE,HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

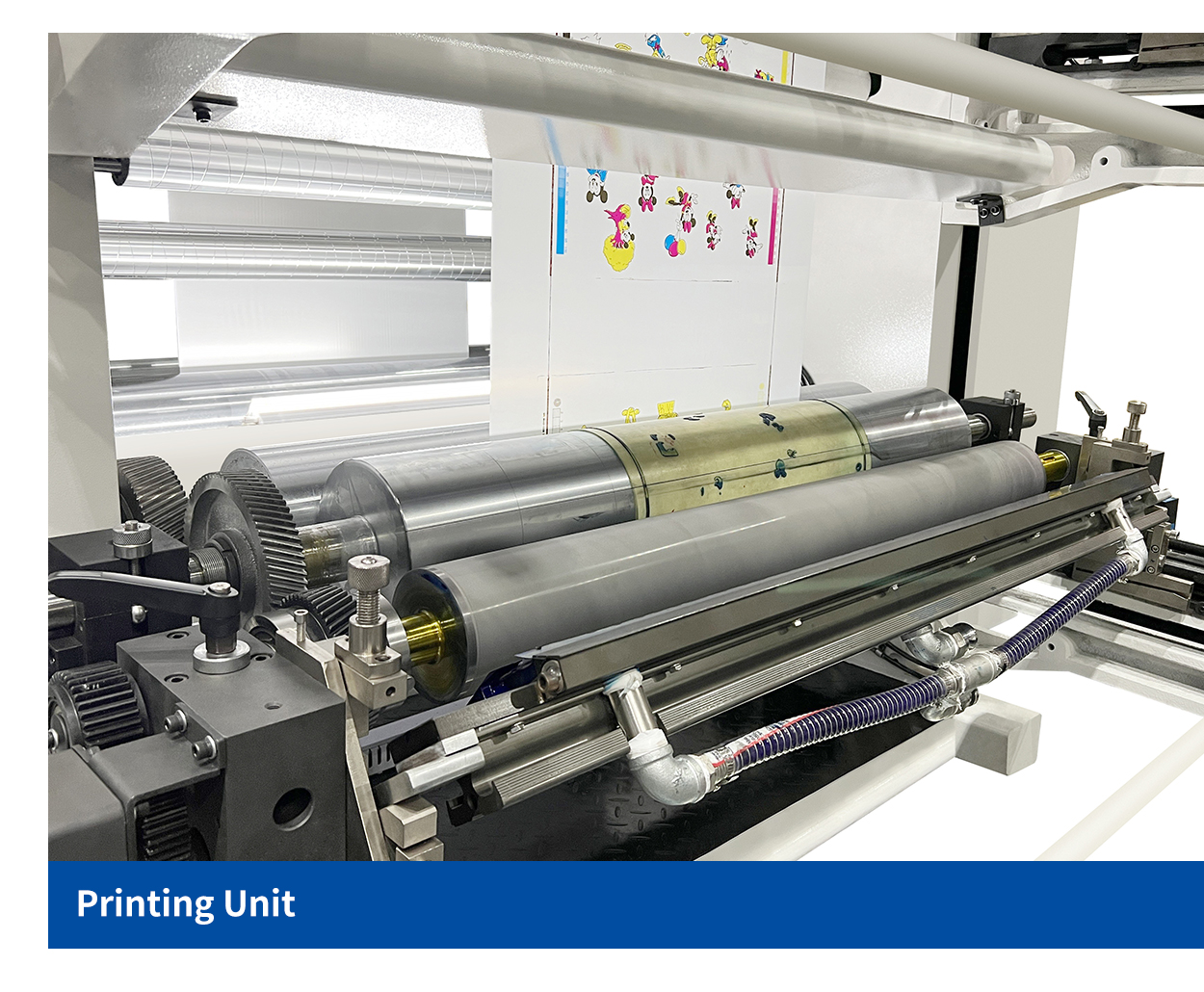

● The corona treatment stack flexographic printing machine is an advanced technology used in the printing industry to produce a wide range of high-quality products such as paper bags, labels, food packaging, medicine packaging and much more.

● The main advantage of this machine is the ability to treat the surface of the printing material with corona. This means that a significant improvement in print quality occurs. Corona is a surface treatment technology used to increase the surface energy of the surface of printing materials, allowing inks and adhesives to better adhere to the surface of the substrate.

● Another important advantage of this machine is its flexibility. It can print on a wide variety of materials, from paper to plastic, and on a wide range of products of different sizes and shapes. In addition, it can be used in a wide variety of applications, from labels to high-quality packaging.

● In addition to producing high-quality prints, the corona treatment stack flexographic printing machine can also be used to produce high-speed prints. This is because prints can be produced at high speed, meaning that large quantities of products can be produced in a short time.

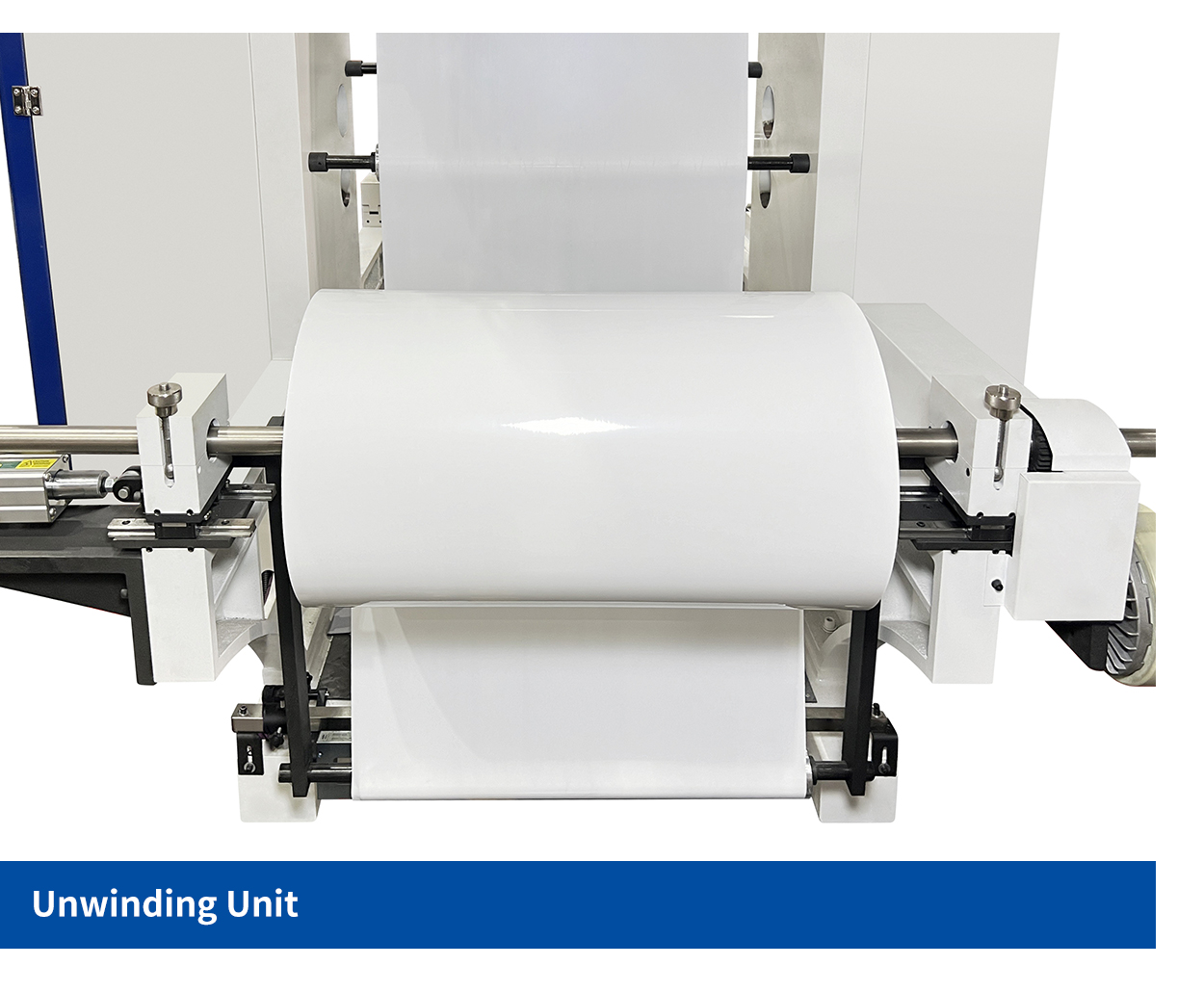

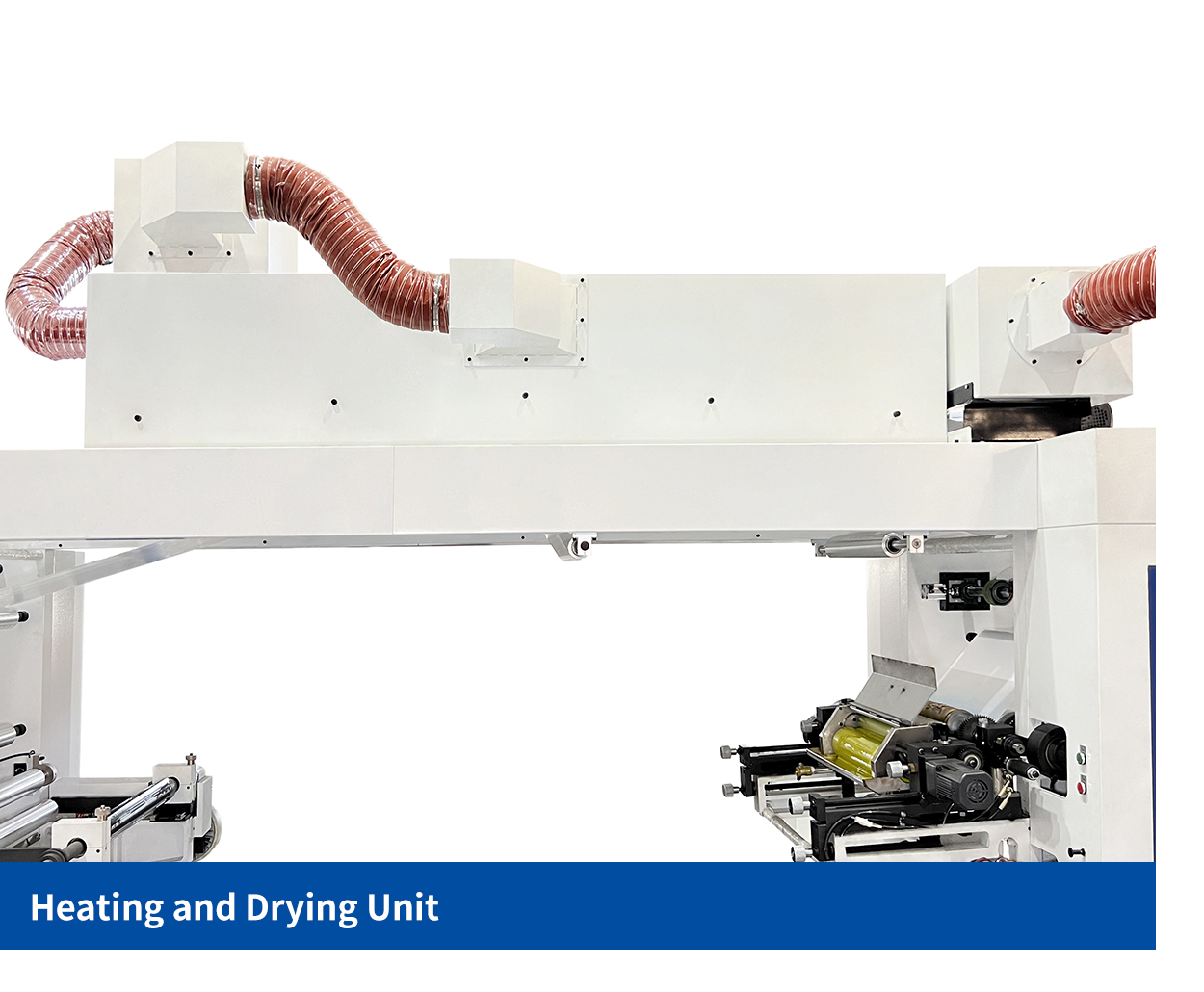

Details Dispaly

sample

We insist to the theory of development of ‘High excellent, Performance, Sincerity and Down-to-earth working approach’ to deliver you with great provider of processing for OEM/ODM Manufacturer Stack Type Plastic Flexo Printing Machine 4 6 8 Colors, We can do your custom-made get to fulfill your own satisfactory! Our company sets up several departments, including output department, revenue department, excellent control department and sevice center, etc.

OEM/ODM Manufacturer 4 Color Flexography Printing Machine and Flexography Printing Machine, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So remember to feel free to contact us for inquiries. You’ll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely supply you with the best quotation and after-sale service. We’re ready to build stable and friendly relations with our merchants. To achieve mutual success, we’ll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we’re here to welcome your inquiries for any of our items and service.