OEM/ODM Supplier 4color Central Drum Type Paper Plastic Packing Flexographic Printing Machine/drum printing machine

OEM/ODM Supplier 4color Central Drum Type Paper Plastic Packing Flexographic Printing Machine/drum printing machine

Persisting in “High top quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients’ large comments for OEM/ODM Supplier 4color Central Drum Type Paper Plastic Packing Flexographic Printing Machine/drum printing machine, We can do your custom-made get to fulfill your own satisfactory! Our company sets up several departments, including output department, revenue department, excellent control department and sevice center, etc.

Persisting in “High top quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients’ large comments for Plastic Printing Machine and Paper Printing Machine, We’ll initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our items or would like to discuss a custom order, remember to feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

Technical Specifications

| Model | CHCI4-600E-S | CHCI4-800E-S | CHCI4-1000E-S | CHCI4-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

Video introduction

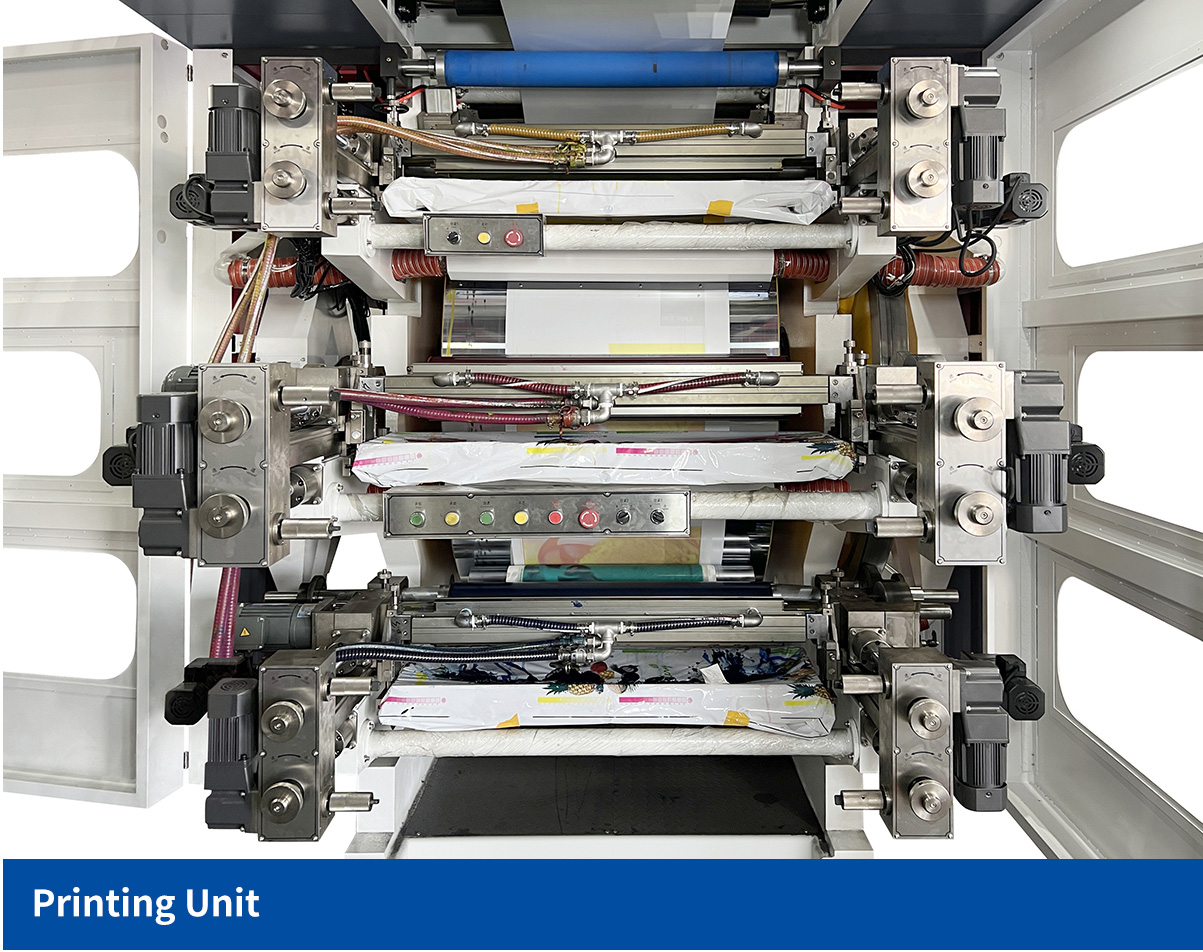

Machine Features

The Central Impression Flexo Press is a highly advanced printing machine that offers a range of features to enhance the efficiency and quality of print production. Here are some of the key features of this machine:

●Advanced Control System: The CI Flexo Printing Machine price comes equipped with an advanced control system that allows you to monitor and control various aspects of the printing process. This control system also includes a user-friendly interface that enables operators to quickly set up and run the press.

●High-Speed Printing: This machine is designed for high-speed printing, which helps reduce turnaround time and improve throughput. It can print up to 300 meters per minute, which means you can produce large quantities of prints in a short amount of time.

●Precise Registration: The Central Drum Flexo Printing Machine uses an automated registration system that ensures perfect registration of all colors. This system is designed to eliminate any misalignment or registration issues that may occur during the printing process.

●Enhanced Drying System: This machine is equipped with an advanced drying system that ensures fast and efficient drying of printed materials. This system helps to reduce downtime and improve overall productivity.

●Multiple Ink Stations: The Central Impression Flexo Press features multiple ink stations that enable you to print with a variety of colors. This feature also allows you to print with specialty inks, such as metallic or fluorescent inks, to create stunning visual effects.

Details Display

Printing Samples

FAQ

Q: What types of printing jobs are best suited for a Central Impression Flexo Press?

A: Central Impression Flexo Presses are ideal for printing jobs that require high-quality prints on a variety of substrates, including:

1. Flexible Packaging – Central Impression Flexo Presses can print on a variety of flexible packaging materials, including plastic film and paper.

2.Labels – Central Impression Flexo Presses can produce high-quality labels for a variety of products.

Q: How do I maintain my Central Impression Flexo Press?

A: Proper maintenance is essential to ensure the longevity of your Central Impression Flexo Press. Here are a few tips to help you maintain your press:

1. Clean your press regularly to remove any dirt or debris that could damage the rollers or cylinders.

2. Check the tension of your press regularly to ensure it is not too loose or too tight.

3. Lubricate your press regularly to prevent it from becoming dry and causing undue wear and tear on the moving parts.

4. Replace any worn parts or components as soon as possible to prevent further damage to the press.

Persisting in “High top quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients’ large comments for OEM/ODM Supplier 4color Central Drum Type Paper Plastic Packing Flexographic Printing Machine/drum printing machine, We can do your custom-made get to fulfill your own satisfactory! Our company sets up several departments, including output department, revenue department, excellent control department and sevice center, etc.

OEM/ODM Supplier Plastic Printing Machine and Paper Printing Machine, We’ll initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our items or would like to discuss a custom order, remember to feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.