Professional Design Ink Viscosity Flexographic Printing - High Speed Central Drum 6 Colour CI Flexo Printing Machine For paper products – Changhong

Professional Design Ink Viscosity Flexographic Printing - High Speed Central Drum 6 Colour CI Flexo Printing Machine For paper products – Changhong

Professional Design Ink Viscosity Flexographic Printing - High Speed Central Drum 6 Colour CI Flexo Printing Machine For paper products – Changhong Detail:

Characteristic

- The machine introduction & absorption of European technology / process manufacturing, supporting / full functional.

- After mounting the plate and registration, no longer need registration, improve yield.

- Replacing 1 set of Plate Roller (unloaded old roller, installed six new roller after tightening), only 20 Minute registration can be done by printing.

- The machine first mount plate, pre-trapping function, to be completed in advance prepress trapping in the shortest possible time.

- Maximum production machine speed up 200m/min, registration accuracy ±0.10mm.

- The overlay accuracy does not change during lifting running speed up or down.

- When machine stop, Tension can be maintained, the substrate is not deviation shift.

- The whole production line from the reel to put the finished product to achieve non-stop continuous production, maximize product yield.

- With precision structural, easy operation, easy maintenance, high degree of automation and so on, only one person can operate.

technical specifications

| Model | CHCI6-600S | CHCI6-800S | CHCI6-1000S | CHCI6-1200S |

| Max. Web value | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing value | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | 50-400g/m2 Paper. Non woven Etc. | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Drying System

It adopts electric heating, which is converted into circulating air heating through a heat exchanger. The temperature control adopts an intelligent temperature controller, a non-contact solid state relay, and a two-way control to adapt to different processes and environmental production, save energy consumption, and realize PID temperature control. Temperature control accuracy ±2℃

Electric control system

- One set of main control panel: the electric control cabinet is designed and manufactured according to IP21 safety protection level; According to setting/modification, operating parameter monitoring/recording, including online help, alarm prompt, historical data record

- The tension control system of the whole machine is controlled by the ultra-light floating roller closed-loop, and is controlled by the PLC to control the human-machine interface and the touch screen to display/set it.

- The whole machine is in jog operation, group control linkage; the main screen can simulate the working process status of the machine. Each power point has work instructions (green constant light), stop instructions (red light flashes), fault indication (red light flashes), single roll length, cumulative length, line speed, and PV value (tension value) at each tension detection point

- The temperature control part has an independent temperature control meter. There are SP and PV value display. Can monitor the working status of all fans in the oven, It has the functions of warning (non-stop) and alarm (stop), and the alarm is released after the fault is eliminated

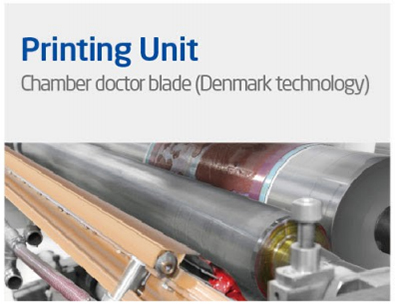

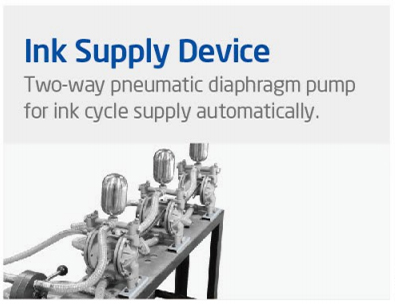

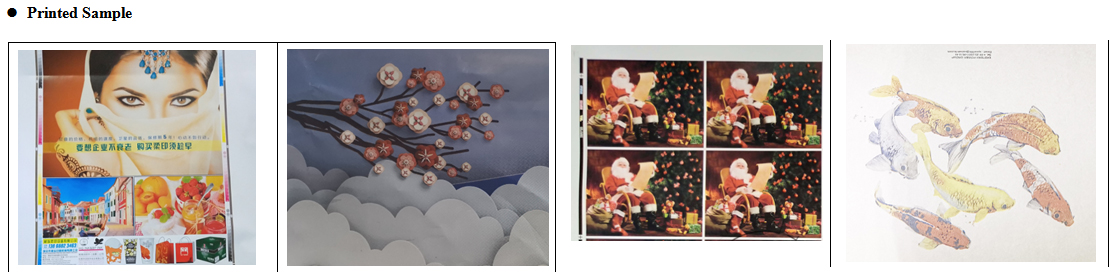

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Professional Design Ink Viscosity Flexographic Printing - High Speed Central Drum 6 Colour CI Flexo Printing Machine For paper products – Changhong , The product will supply to all over the world, such as: United Arab emirates, Mumbai, Zimbabwe, We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

Write your message here and send it to us