Short Lead Time for ci Flexo Printing Machine Printing Press Labels & Film Printing Machine Flexography Printing Machine Flexographic Printing Press

Short Lead Time for ci Flexo Printing Machine Printing Press Labels & Film Printing Machine Flexography Printing Machine Flexographic Printing Press

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for Short Lead Time for ci Flexo Printing Machine Printing Press Labels & Film Printing Machine Flexography Printing Machine Flexographic Printing Press, We’re not content together with the present achievements but we have been trying greatest to innovate to satisfy buyer’s more personalized needs. No matter where you’re from, we are here to wait for your type ask for, and welcom to visit our manufacturing unit. Choose us, you can meet your reputable supplier.

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for Flexo Printing Press and Flexographic Printing Machine, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Technical Specifications

| Model | CHCI6-600J-S | CHCI6-800J-S | CHCI6-1000J-S | CHCI6-1200J-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

The central drum flexographic printing machine with double-sided printing has several important advantages that make it an attractive option in the printing market.

1. Versatility: The central drum flexographic printing machine can print on a wide variety of packaging materials, such as plastic, paper, and more. In addition, the ability to print double-sided allows designers to have more creative options and obtain more useful information.

2. Efficiency: Double-sided printing reduces production time and costs, as there is no need to reinsert the material into the machine to print the other side. In addition, the central drum flexographic printing machine is compatible with automation to increase production efficiency.

3. Quality: Flexographic printing technology is known for producing crisp, high-quality prints. The flexibility of the process allows for precise, detailed printing on irregular or curved surfaces, which is especially important for label and packaging printing.

4. Sustainability: Flexographic printing technology uses water-based inks and environmentally friendly materials. Additionally, the ability to print double-sided helps reduce material waste and maximize resource usage.

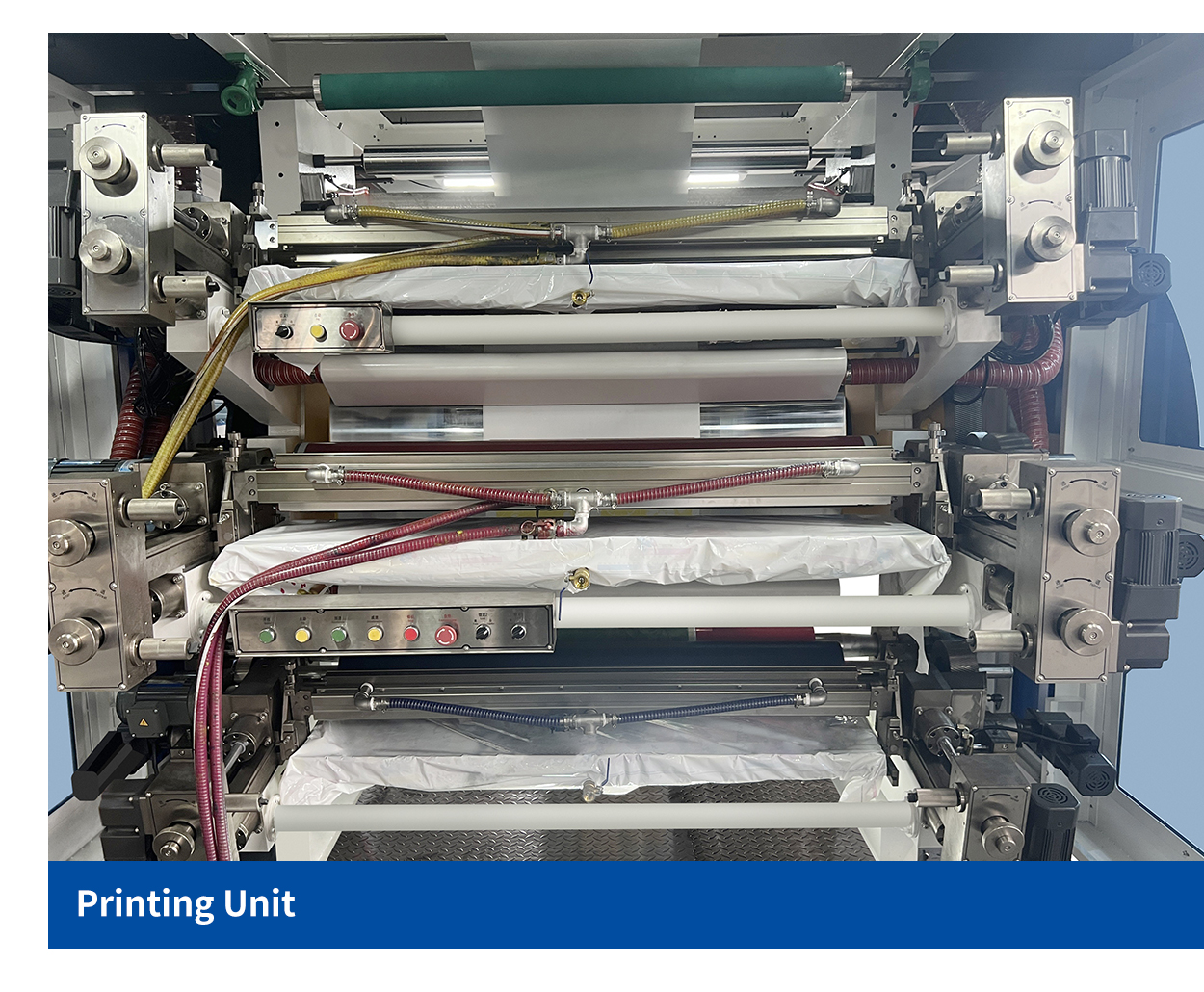

Details Dispaly

Printing samples

Packaging and Delivery

Q: Are you a factory or trading company?

A: We are a factory, the real manufacturer not trader.

Q: Where is your factory and how can I visit it?

A: Our factory is located in fuding City, fujian Province, China about 40 minutes by plane from Shanghai ( 5 hours by train)

Q: What is your after-sale service?

A: We have been in flexo printing machine business for many years, we will send our professional engineer to install and test machine.

Beside, we can also provide online support, video technical support, matching parts delivery, etc. So our after-sales services is always reliable.

Q: How to get machines price?

A: Pls provide following information:

1)The color number of printing machine;

2)Material width and effective print width;

3)What material to print;

4)The photo of printing sample.

Q: What services do you have?

A: 1 Year Guarantee !

100% Good Quality !

24 Hours online Service!

The buyer paid tickets ( go and back to FuJian), and pay 150usd/day during the install and testing period!

We’re going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for Short Lead Time for ci Flexo Printing Machine Printing Press Labels & Film Printing Machine Flexography Printing Machine Flexographic Printing Press, We’re not content together with the present achievements but we have been trying greatest to innovate to satisfy buyer’s more personalized needs. No matter where you’re from, we are here to wait for your type ask for, and welcom to visit our manufacturing unit. Choose us, you can meet your reputable supplier.

Short Lead Time for Flexo Printing Press and Flexographic Printing Machine, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.