Special Design for Advanced Gearless Flexo Printing Press Machine 6 colour for Paper non woven Bags

Special Design for Advanced Gearless Flexo Printing Press Machine 6 colour for Paper non woven Bags

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for Special Design for Advanced Gearless Flexo Printing Press Machine 6 colour for Paper non woven Bags, Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for Paper CI gearless Flexo Printing Machine and Advanced Flexographic Printing Machine 4 6 8 Color, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

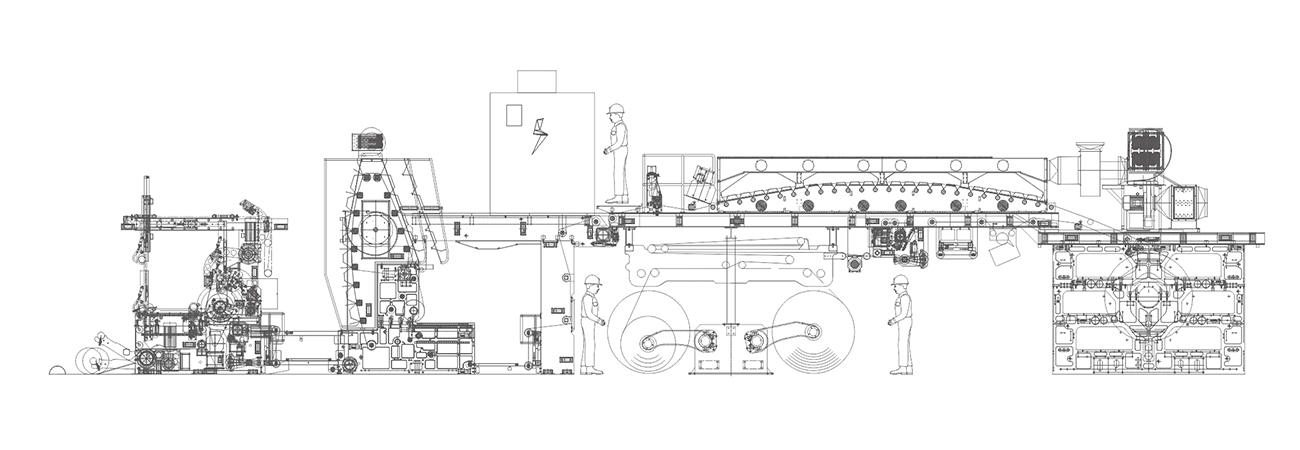

Material Feeding Diagram

technical specifications

| Model | CHCI6-600F-Z | CHCI6-800F-Z | CHCI6-1000F-Z | CHCI6-1200F-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 500m/min | |||

| Max. Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1200mm/Φ1500mm | |||

| Drive Type | Gearless full servo drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 400mm-800mm | |||

| Range Of Substrates | Non woven、Paper、Paper cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

● This ci flexo printing machine adopts gearless full-servo drive technology, achieving ultra-high registration accuracy of ±0.1mm. The groundbreaking 6+1 printing unit configuration enables double-sided synchronous printing at speeds up to 500 m/min, effortlessly supporting multi-color overprinting and fine halftone dot reproduction.

● The flexographic printer effectively prevents paper deformation and ensures uniform pressure across all printing units. The advanced ink delivery system, paired with a closed-chamber doctor blade device, delivers vibrant and saturated color reproduction. It excels in both large solid color areas and intricate line details, meeting the demands of premium-quality printing applications.

● Optimized for paper substrates, this flexo printer also accommodates non-woven fabrics, cardboard, and other materials. Its innovative drying system and tension control technology adapt seamlessly to substrates of varying weights (80gsm to 400gsm), ensuring consistent print results across delicate thin papers and heavy-duty cardstock.

● Featuring modular construction and an intelligent control system, the flexo press automates functions like one-click job changeovers and automatic registration. Compatible with eco-friendly water-based and UV inks, it integrates energy-efficient drying systems to reduce power consumption and VOC emissions significantly. This aligns with modern green printing trends while boosting productivity.

Details Dispaly

Printing Samples

Packaging And Delivery

Reliable top quality and great credit score standing are our principles, which will help us at a top-ranking position. Adhering on the tenet of “quality first, consumer supreme” for Special Design for Advanced Gearless Flexo Printing Machine for Custom Paper Bags, Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Special Design for Paper CI gearless Flexo Printing Machine and Advanced Flexographic Printing Machine 4 6 8 Color, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.