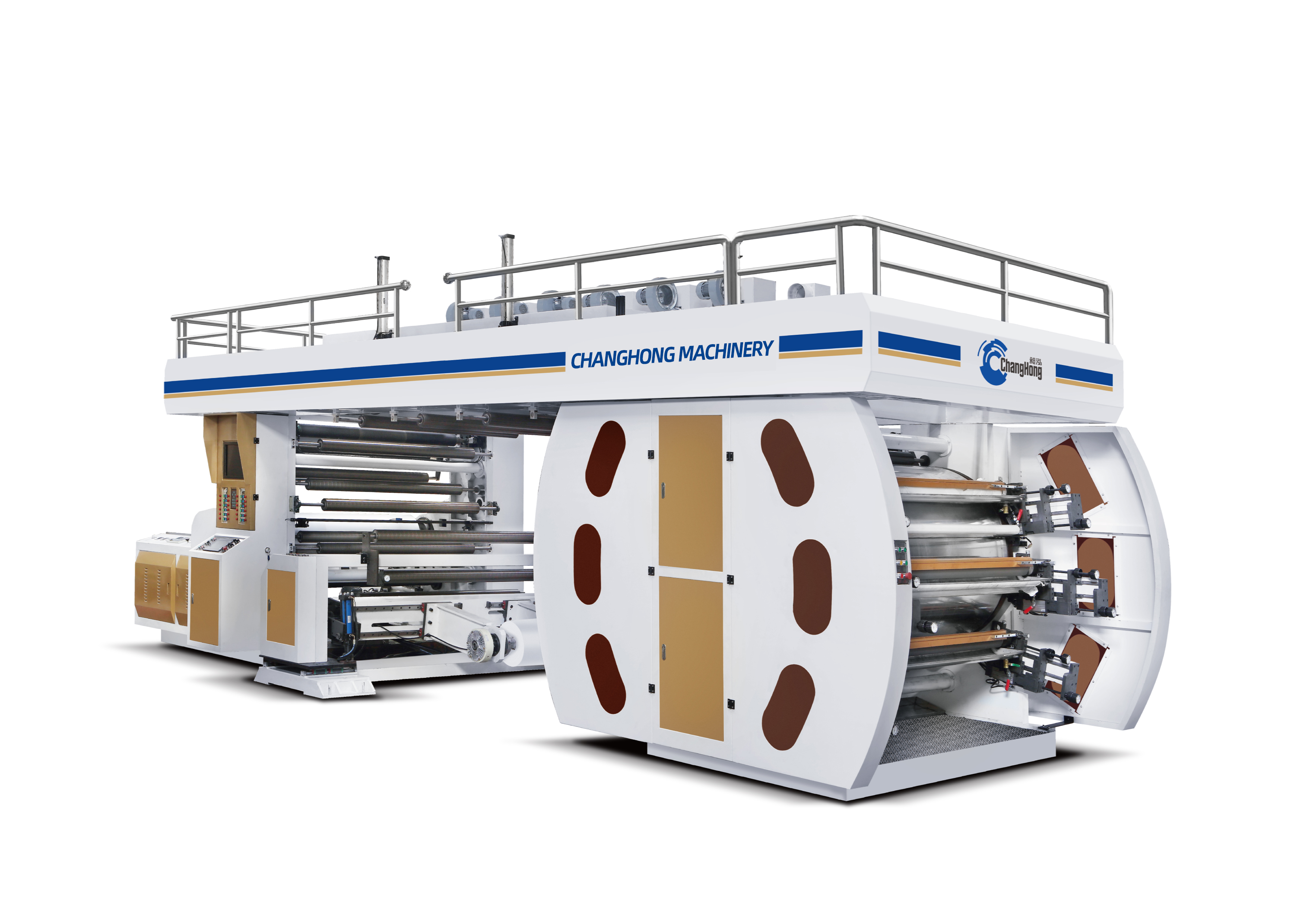

Super Purchasing for Professional 8 Color Central Impression Flexo Printing Press with Servo winder for Film

Super Purchasing for Professional 8 Color Central Impression Flexo Printing Press with Servo winder for Film

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Super Purchasing for Professional 8 Color Central Impression Flexo Printing Press with Servo winder for Film, Sincerely hope we’re increasing up along with our buyers all around the entire world.

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Automatic Ci Flexo Printer and Non-Stop CI Flexo Printing Machine 8 Color, Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Production Description

technical specifications

| Model | CHCI8-600E-S | CHCI8-800E-S | CHCI8-1000E-S | CHCI8-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. Central Impression Drum Structure for Exceptional Accuracy: The robust central impression design positions all eight printing stations around a single, shared cylinder. This fundamentally guarantees unparalleled register accuracy and stability during high-speed operation, making it particularly suitable for stretch-prone materials like films.It is the core feature ensuring the high-precision output characteristic of CI flexographic printing machine .

2.Servo Unwind & Rewind unit: Key unwind and rewind stations use high-performance servo drives, paired with a central closed-loop tension system. It nails consistent tension from start to finish—keeps materials flat, no flutter, even during high-speed starts, stops, and full production runs.

3.High-Speed Stable Printing for Strong Mass-Production Performance: With eight high-performance printing units, it runs stably at high speeds. Perfect for high-volume continuous printing needs—operates smoothly, ramps up print productivity.

4.Cost-Effective, Reliable & Durable: Critical parts of the CI flexographic printing press integrate advanced tech, while the overall structure and setup are optimized. Strikes a balance between top performance and cost-effectiveness. A solid mechanical base ensures long-term reliability and low maintenance costs.

5.Intelligent Operation Boosts Efficiency: User-friendly centralized control simplifies presets, registration, and monitoring—super easy to operate. The servo-driven unwind/rewind tension system adapts perfectly to roll changes, enabling fast roll swaps and setup tweaks. Cuts downtime significantly, ramps up overall production efficiency.

Details Dispaly

Printing Samples

Our CI flexo press works great for plastic film printing—fits mainstream substrates like PP, PE and PET. Samples apply to food packaging films, beverage labels, snack bags and daily sleeves, meeting both prototyping and mass-production needs for food & beverage and daily film packaging. Printed samples have sharp graphics and solid adhesion: crisp intricate logos, complex patterns and natural color gradients that fully meet high-end film packaging standards.

We use food-safe eco inks for all samples—no odors, great adhesion that resists fading or ink peeling during stretching and lamination. The press enables stable large-scale production with consistent colors, high yields and close proof matching, reliably supporting scaled-up output to boost your film packaging market competitiveness.

Our Services

We’ve got full-cycle services for your CI flexo press.Pre-sales: one-on-one consulting, detailed demos to find the right setup, plus custom tweaks for substrates, inks and functions.After-sales: on-site installation, operator training, timely maintenance and genuine parts—all to keep production running smooth.We follow up regularly, and dedicated technical support’s there anytime for post-operation questions.

Packaging and Delivery

We package this CI flexographic printing machine professionally and securely—full protection against transport damage, so it arrives intact. We can also offer custom packaging advice if you have specific route or environment needs.

For delivery, we team up with trusted logistics firms skilled in heavy machinery transport. Loading, unloading and shipping all follow strict safety rules. We keep you posted on logistics in real time every step of the way, and we’ll provide all the required paperwork too. After delivery, we provide on-site acceptance guidance to make installation and commissioning go smoothly, so the whole process is completely hassle-free.

FAQ

Q1: What are the core advantages of the servo unwinding and rewinding system for film printing?

A1: Servo unwinding/rewinding nails tension control, fits film stretch, stops deviation and wrinkling, keeps continuous mass production stable.

Q2: Why is this CI flexo printer more suitable for high-precision plastic film printing?

A2: The CI central drum spreads force evenly—no film stretching, no deformation, just steady registration accuracy.

Q3: What problem can the EPC automatic correction function solve for film printing?

A3: Catches printing deviations real-time, corrects them right on point—avoids misregistration and pattern offset, boosts qualification rates.

Q4: How do 8 printing units boost plastic film packaging printing?

A4: 8 units serve up richer, brighter colors—handles gradients and intricate patterns with ease, perfect for premium film packaging samples.

Q5: Can the CI flexo machine meet the demand for mass continuous production of plastic films?

A5: Hits stable high-speed printing up to 350 m/min, fits continuous mass production, balances efficiency and precision.

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Super Purchasing for Professional 8 Color Central Impression Flexo Printing Press with Servo winder for Film, Sincerely hope we’re increasing up along with our buyers all around the entire world.

Super Purchasing for Automatic Ci Flexo Printer and Non-Stop CI Flexo Printing Machine 8 Color, Our company upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.