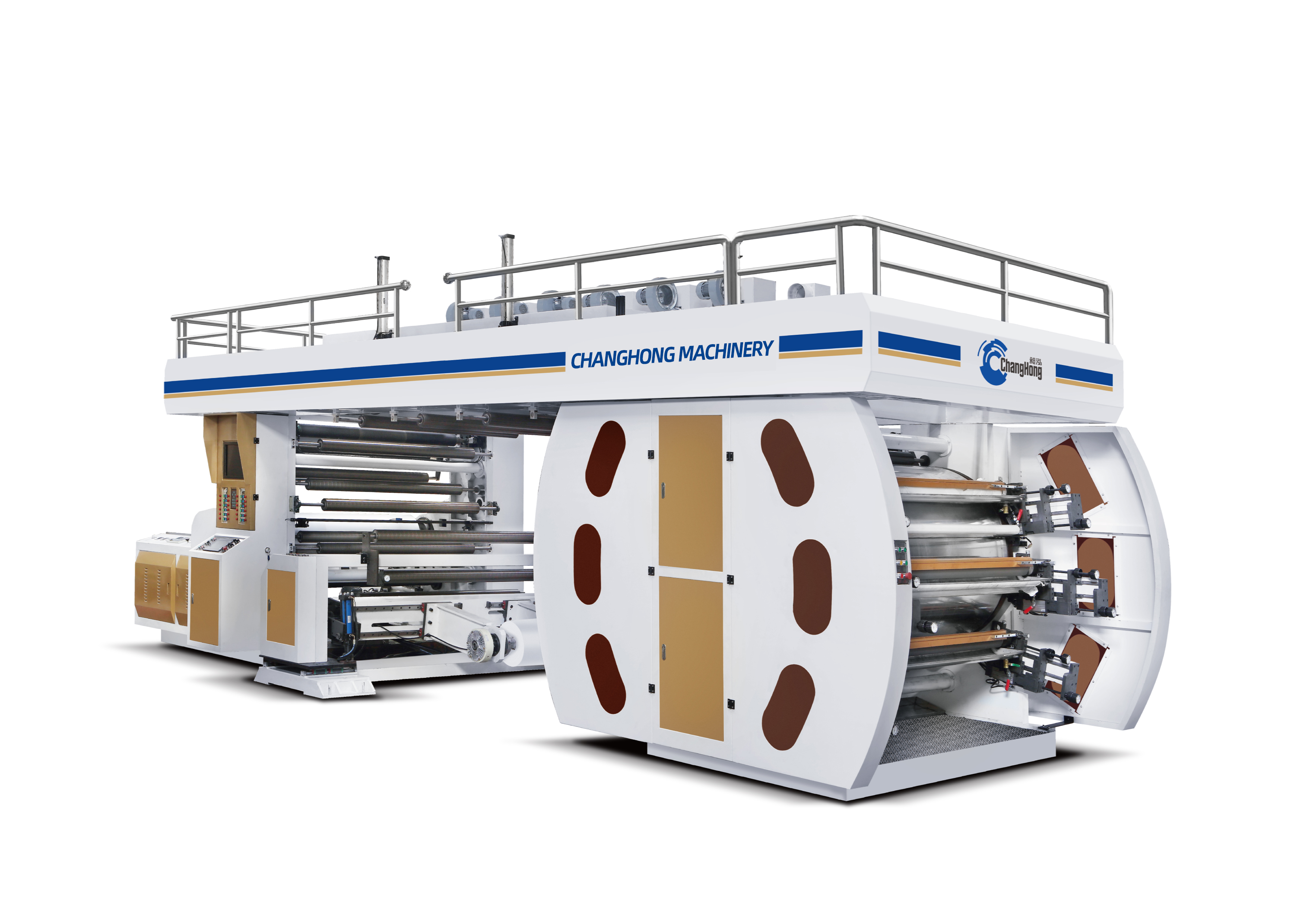

Supply OEM Hot Sale Factory Price 2 4 6 8 Colour Roll to Roll Plastic Film PP Woven Bag CI Type Flexo Flexographic Printing Press Machine Manufacturer

Supply OEM Hot Sale Factory Price 2 4 6 8 Colour Roll to Roll Plastic Film PP Woven Bag CI Type Flexo Flexographic Printing Press Machine Manufacturer

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Supply OEM Hot Sale Factory Price 2 4 6 8 Colour Roll to Roll Plastic Film PP Woven Bag CI Type Flexo Flexographic Printing Press Machine Manufacturer, Standing still today and seeking into the longer term, we sincerely welcome customers all over the environment to cooperate with us.

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for CI Flexo Printing Press and Flexo Printer Machine, With the advanced workshop, skilled design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our solutions are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

technical specifications

| Model | CHCI4-600J-Z | CHCI4-800J-Z | CHCI4-1000J-Z | CHCI4-1200J-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | PP Woven Bag、Non Woven 、Paper、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

● High-Speed, High-Efficiency, and Precise Registration:This 4 color ci flexo printing machine adopts advanced central impression drum technology, ensuring precise alignment of all printing units for stable, high-speed multicolor printing. With exceptional registration accuracy, it delivers outstanding print quality even under high-capacity production, significantly improving efficiency to meet large-volume order demands.

● Corona Pretreatment for Enhanced Print Adhesion:The ci flexographic printing press integrates an efficient corona treatment system to activate the surface of PP woven bags before printing, significantly improving ink adhesion and preventing issues like peeling or smudging. This feature is particularly suitable for non-polar materials, ensuring durable and sharp patterns even at high production speeds.

● Intuitive Operation and Wide Material Compatibility:The control system is equipped with a video inspection System, enabling intuitive parameter adjustments and reducing reliance on highly skilled operators. It accommodates PP woven bags, valve sacks, and other materials of varying thicknesses, with quick plate-changing flexibility to easily handle diverse packaging printing needs.

● Energy-Efficient and Eco-Friendly, Reducing Production Costs:The flexo press optimizes ink transfer and drying energy consumption, minimizing waste while lowering power usage. Compatible with water-based or eco-friendly inks, it meets green printing standards—reducing environmental impact and helping businesses cut long-term operational costs.

Details Dispaly

Printing Samples

Packaging And Delivery

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Supply OEM Hot Sale Factory Price 2 4 6 8 Colour Roll to Roll Plastic Film PP Woven Bag CI Type Flexo Flexographic Printing Press Machine Manufacturer, Standing still today and seeking into the longer term, we sincerely welcome customers all over the environment to cooperate with us.

Supply OEM CI Flexo Printing Press and Flexo Printer Machine, With the advanced workshop, skilled design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our solutions are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.