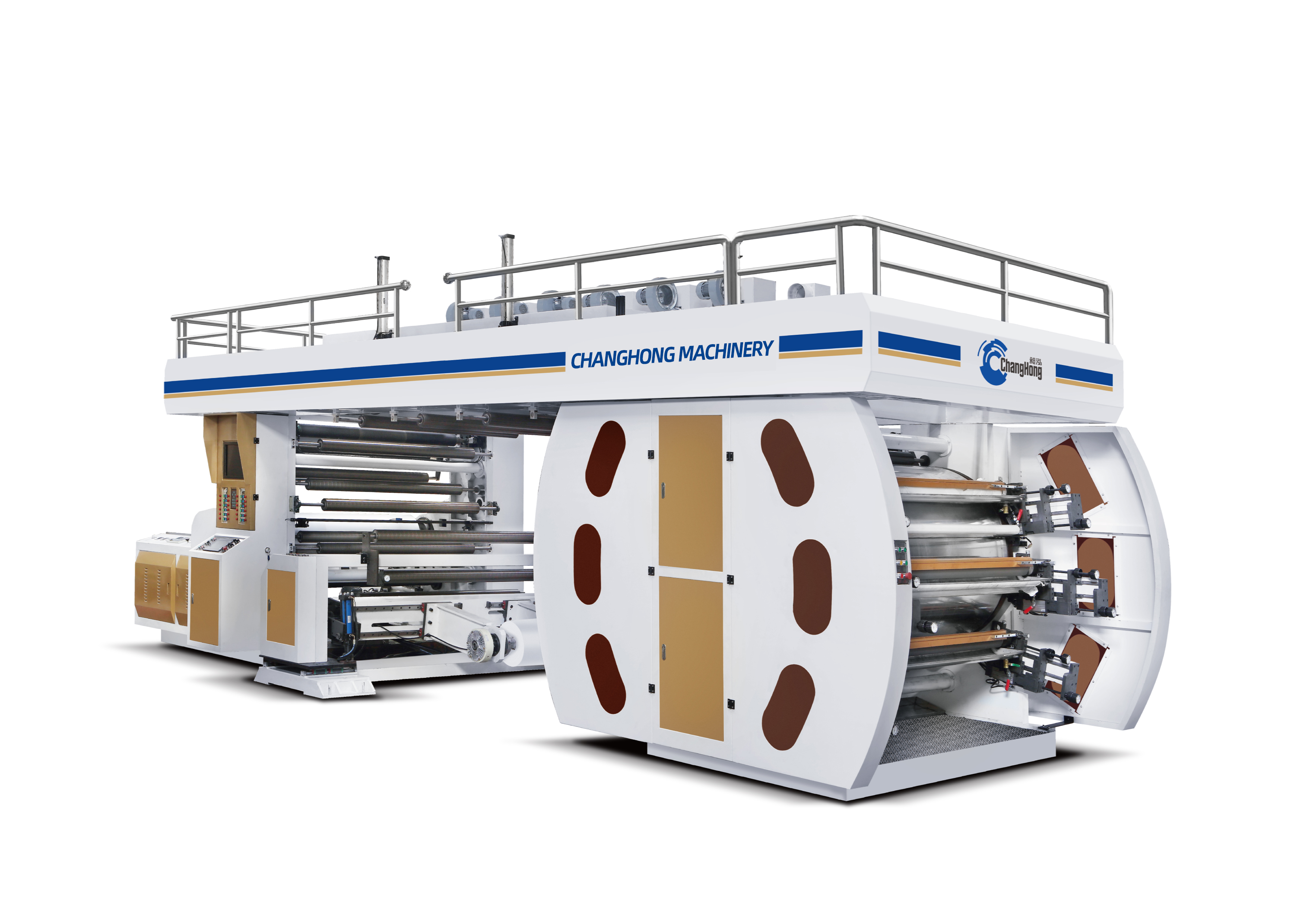

Three Unwinder & Three Rewinder Stack Flexo press

Three Unwinder & Three Rewinder Stack Flexo press

technical specifications

| Model | CH4-600B-S | CH4-800B-S | CH4-1000B-S | CH4-1200B-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 560mm | 760mm | 960mm | 1160mm |

| Max. Machine Speed | 120m/min | |||

| Max. Printing Speed | 100m/min | |||

| Max.Unwind/Rewind Dia. | Φ600mm | |||

| Drive Type | Synchronous belt drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 300mm-1300mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

1. High production capacity: The three-unwinder, three-rewinder stacked flexo press has a fast printing speed and high output, allowing large quantities of labels and packaging to be produced in a short time.

2. Registration accuracy: The registration system of this press is highly accurate, ensuring superior print quality and perfect alignment of designs.

3. Flexibility: The three-unwinder, three-rewinder stacked flexo press can handle a wide variety of substrates, such as paper, cardboard, plastic film, and other materials, making it perfect for printing different products.

4. Easy operation: The machinery features a simple and intuitive control system, making it easy to use and reducing human error.

5. Low maintenance: The stacked flexo press with three unwinders and three rewinders has a robust and high-quality design that requires little maintenance and has a long service life.

Details Dispaly

sample