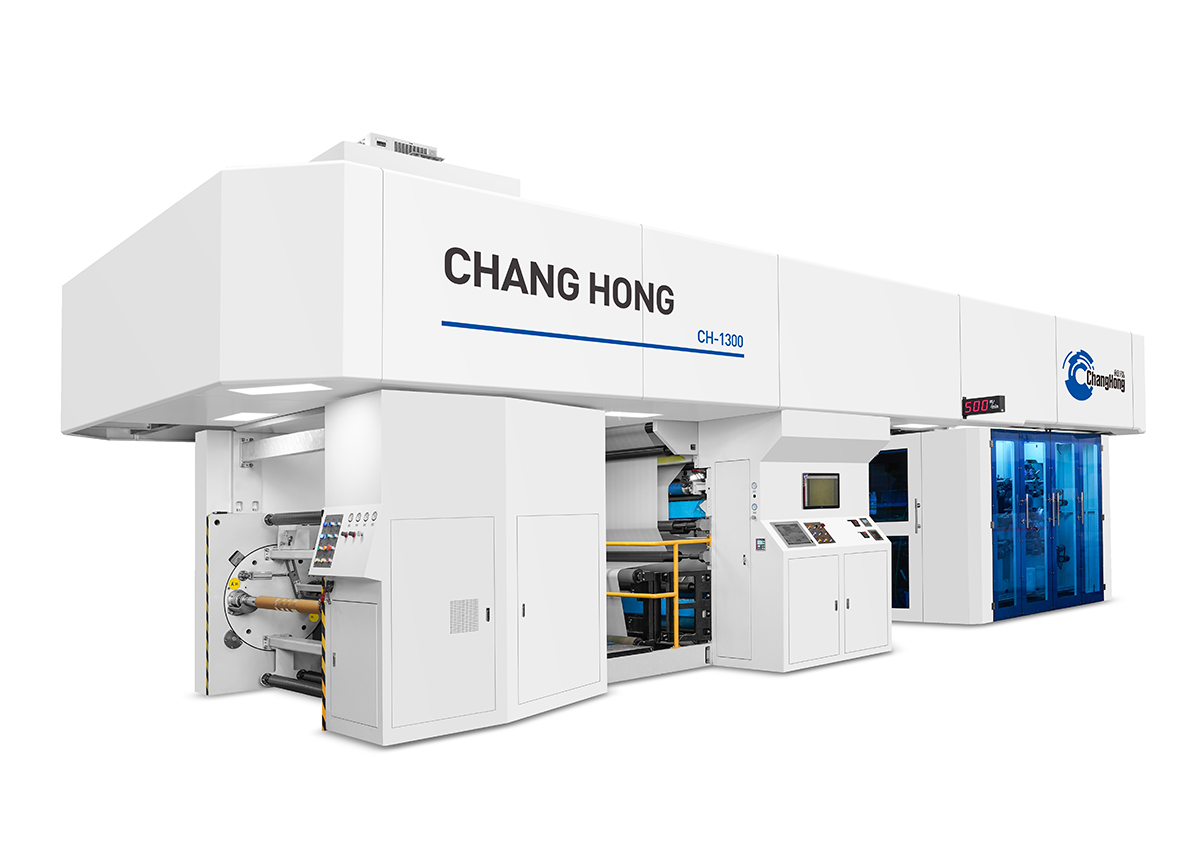

8 COLOR DOUBLE STATION NON-STOP UNWINDER/REWINDER CI FLEXOGRAPHIC PRINTER/FLEXO PRINTING MACHINE

8 COLOR DOUBLE STATION NON-STOP UNWINDER/REWINDER CI FLEXOGRAPHIC PRINTER/FLEXO PRINTING MACHINE

Technical Specifications

|

Model |

CHCI8-600E-S |

CHCI8-800E-S |

CHCI8-1000E-S |

CHCI8-1200E-S |

|

Max. Web Width |

700mm |

900mm |

1100mm |

1300mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

350m/min |

|||

|

Max. Printing Speed |

300m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1000mm/Φ1200mm |

|||

|

Drive Type |

Central drum with Gear drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

Video Introduction

Machine Features

1. Double-Station Non-Stop Unwinding/Rewinding for Seamless Operation:The CI flexographic printer features a dual-station non-stop unwind/rewind system, eliminating downtime during material changes. Whether handling large-volume orders or urgent tasks, it maintains continuous high-speed production,ensuring optimal resource utilization while delivering consistent, high-quality output—empowering your production line with uninterrupted performance.

2. Central Impression Drum Ensures Precise Registration:With its CI (Central Impression) drum design and a rigid frame structure, this ci flexo printing machine delivers exceptional registration accuracy even at top speeds. From fine halftones to complex multicolor overprints, every detail remains sharp and consistent, meeting the strictest demands of high-end packaging.

3. Multi-Material Mastery for Expanded Packaging Possibilities:The ci flexo printing machine effortlessly handles a wide range of flexible substrates, including films, plastics, and nylon. Its advanced tension control and adjustable print pressure ensure stable, high-quality results across different materials, making it a reliable solution for various packaging demands.

4.Unmatched Speed and Precision to Meet Stringent Production Demands:

This CI flexo press redefines efficiency and accuracy by combining ultra-high printing speeds with unwavering color consistency. Its intelligent control system monitors production parameters in real time, ensuring reliable operation while maximizing output—driving superior results for your production needs.

Details Display

Details Display