The 6+1 Color Gearless CI Flexo Printing Press is a high-efficiency machine engineered for non-woven paper, kraft paper, and flexible materials (20-400gsm). It combines advanced gearless full servo drive technology to deliver ultra-precise registration, high-speed production, and superior print quality—with dual-side printing and integrated slitting for seamless finishing.

● Technical Specifications

|

Model |

CHCI6-600F-Z |

CHCI6-800F-Z |

CHCI6-1000F-Z |

CHCI6-1200F-Z |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

500m/min |

|||

|

Max. Printing Speed |

450m/min |

|||

|

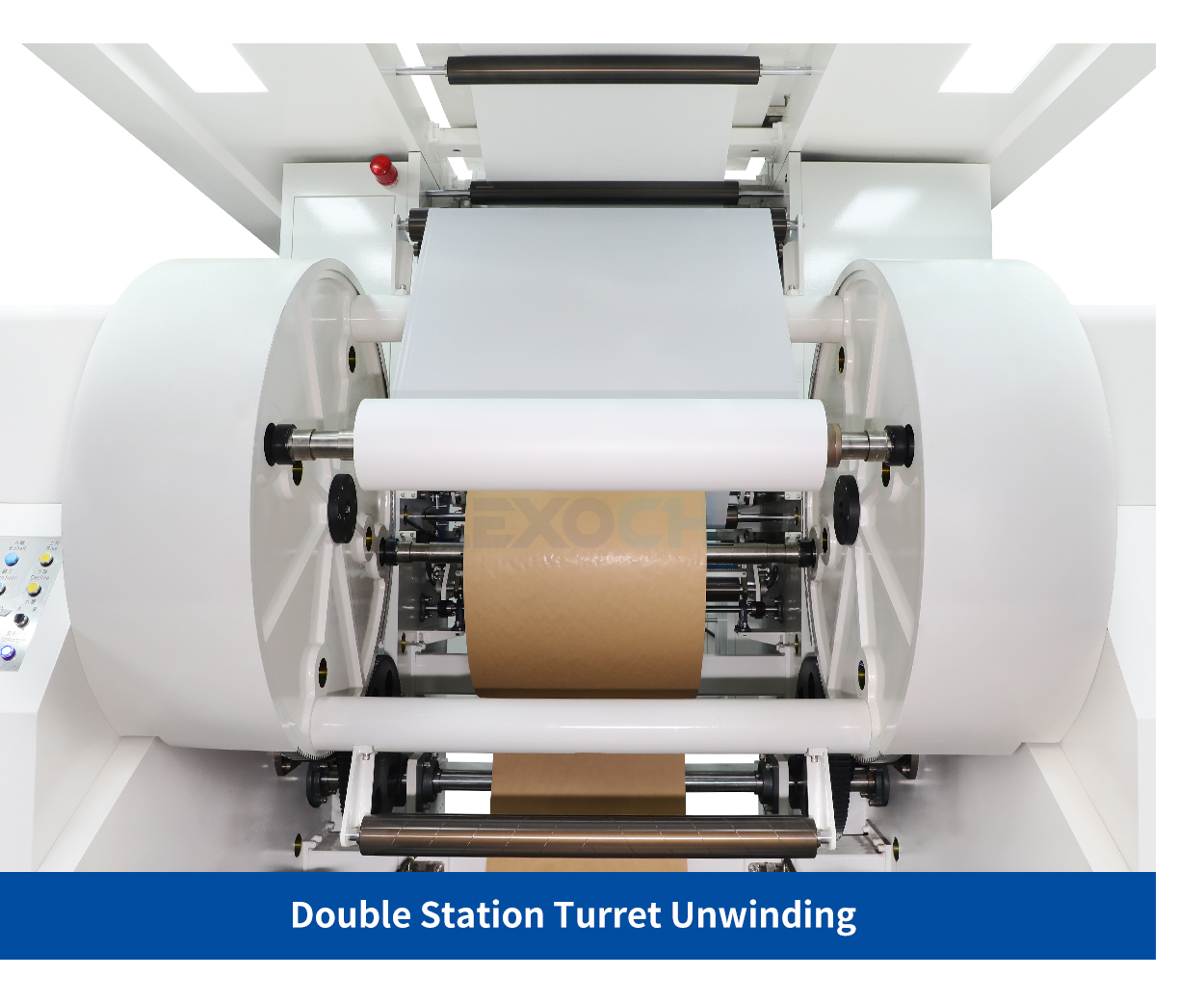

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1200mm/Φ1500mm |

|||

|

Drive Type |

Gearless full servo drive | |||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

400mm-800mm |

|||

|

Range Of Substrates |

non woven、paper、paper cup | |||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

● Video Introduction

● Machine Features

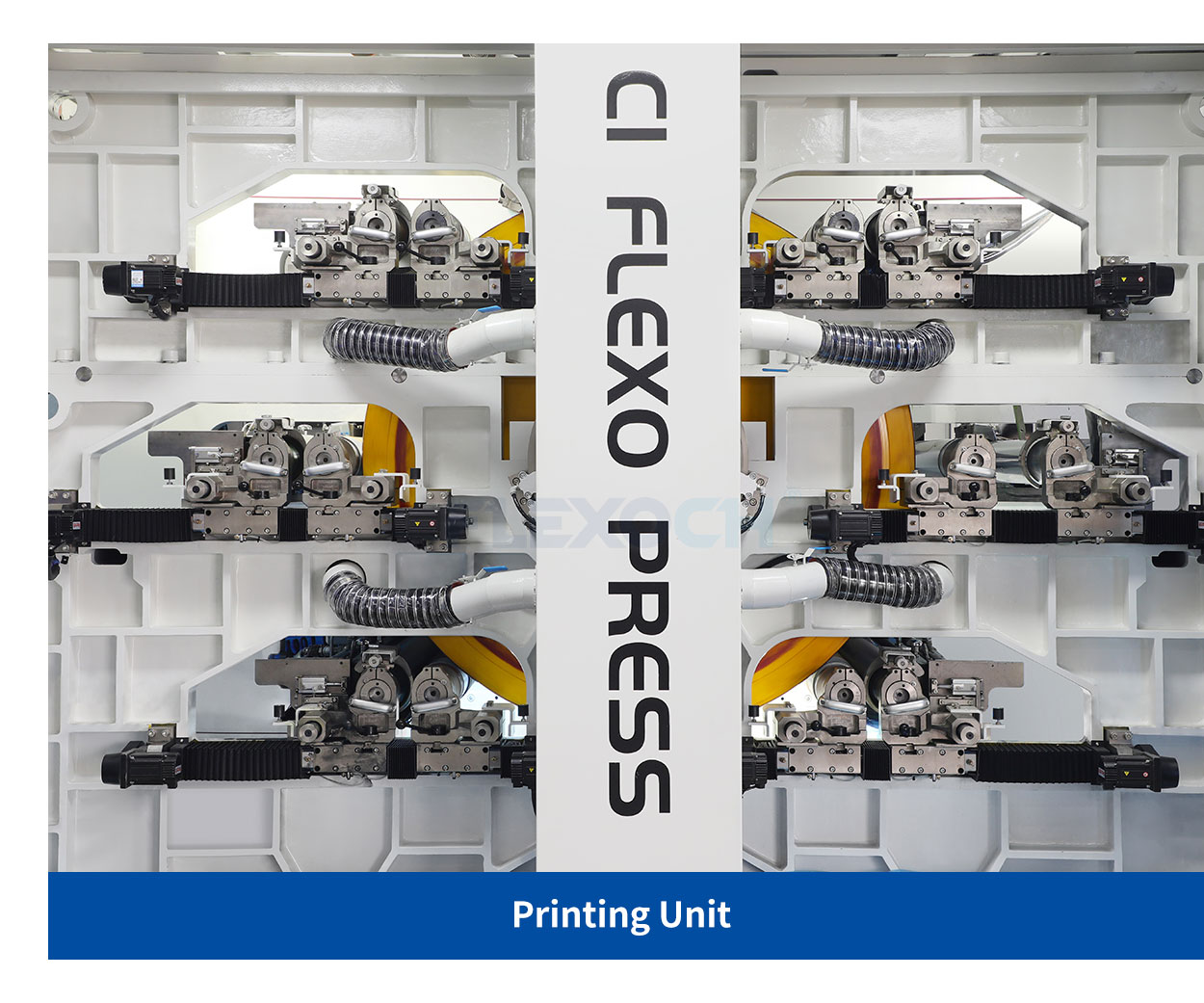

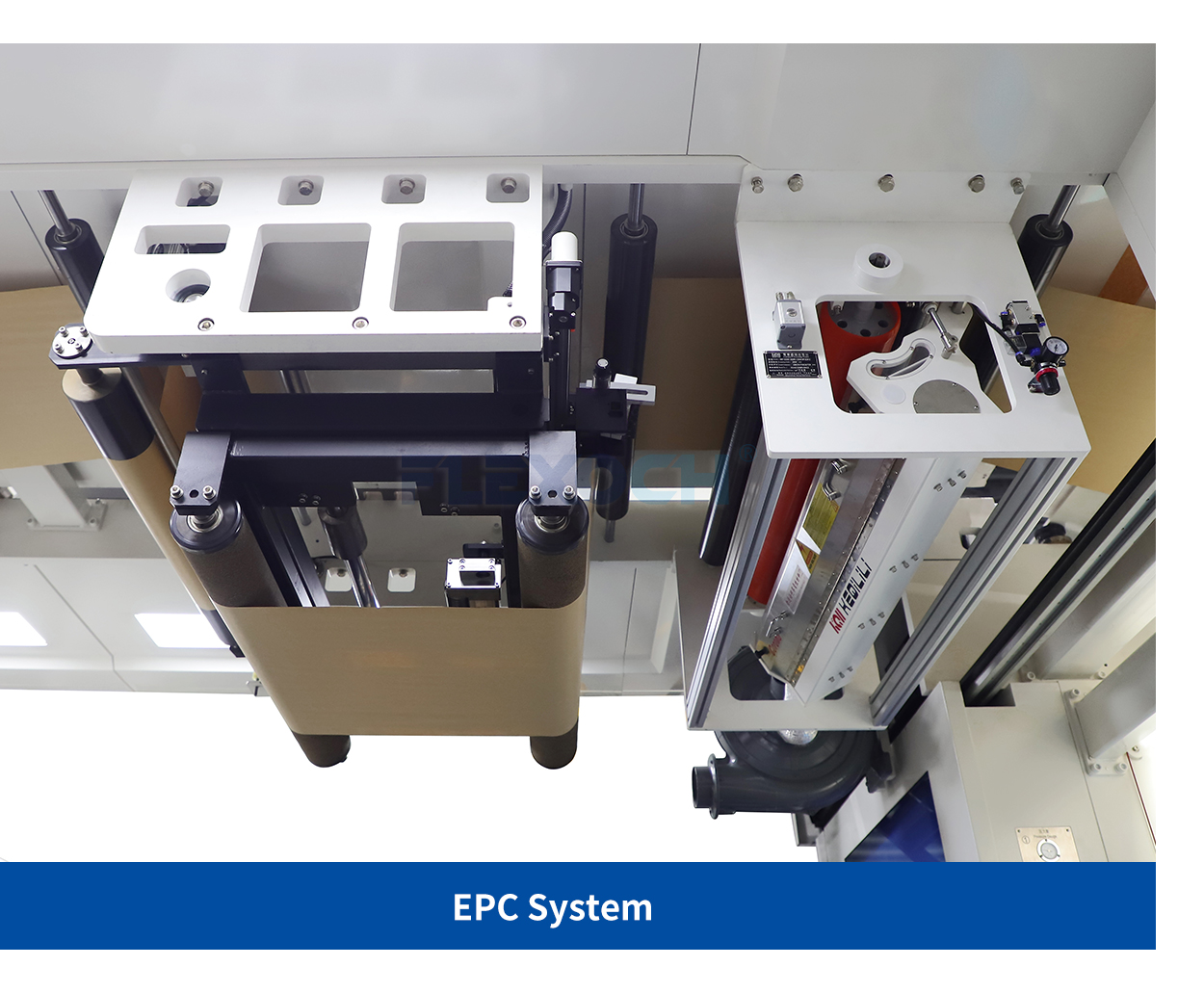

1.Unmatched Printing Precision & Quality:Unmatched Printing Precision and Quality: The flexo printer adopts gearless full servo drive technology , delivering industry-leading accuracy of ±0.1mm. This ensures perfect registration and sharp, clear printing results even at speeds up to 500 meters per minute. Its dual-sided printing capability sets this flexo press apart, maintaining consistent quality on both sides of the material.

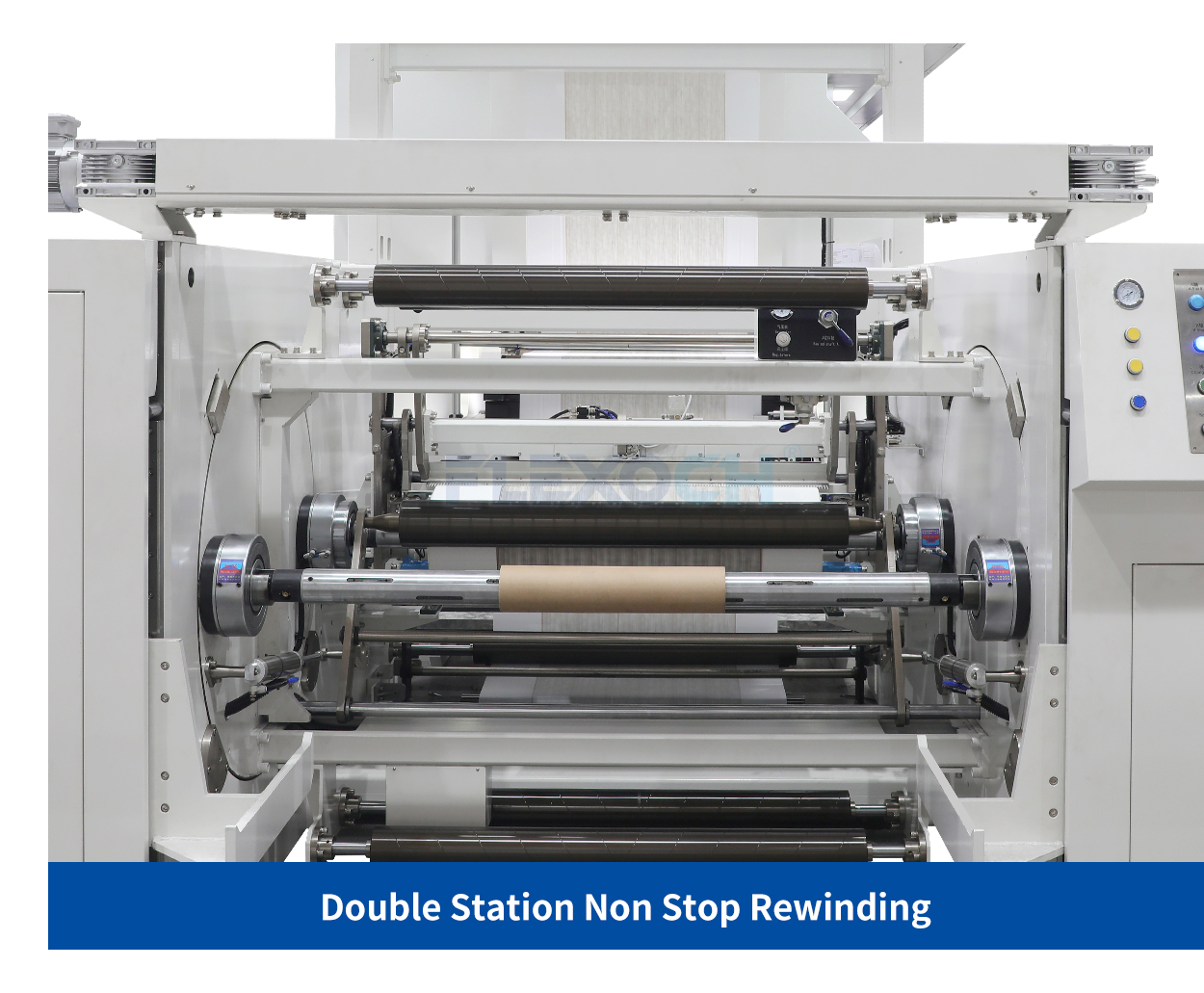

2.High Efficiency with Integrated Slitting Function:The innovative CI flexo printing machine features a unique 6+1 color setup that enables genuine dual-side multicolor printing. Combined with integrated slitting, this flexographic system provides complete single-pass processing for the most efficient production of premium packaging.

3.Versatile Material Compatibility & Eco-Friendly Operation:This CI flexographic printing press accommodates an exceptional range of materials (20-400gsm), from delicate non-wovens to sturdy kraft papers. The flexo-optimized design supports sustainable operations with eco-friendly ink systems and energy-efficient performance.

4.Intelligent Automation for Uninterrupted Production:Engineered for modern manufacturing, this CI flexographic printing press features smart automation that minimizes manual intervention. With self-diagnostic systems and quick-change components, it delivers maximum uptime and productivity in continuous operation environments.

● Details Dispaly

● Printing Samples

Post time: May-27-2025