Changhong High-Speed 6 Color Gearless Flexo Printing Press adopts innovative Gearless full servo drive technology, paired with a dual-station non-stop roll-changing system. Designed specifically for paper and non-woven materials, it delivers efficient and stable high-precision printing, enhancing production efficiency. Its advanced modular design allows for flexible adjustments to meet diverse production needs, making it an ideal solution for those seeking high-quality printing and continuous batch production.

● Technical Specifications

|

Model |

CHCI6-600F-Z |

CHCI6-800F-Z |

CHCI6-1000F-Z |

CHCI6-1200F-Z |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

500m/min |

|||

|

Max. Printing Speed |

450m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1200mm/Φ1500mm |

|||

|

Drive Type |

Gearless full servo drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

400mm-800mm |

|||

|

Range Of Substrates |

non woven、paper、paper cup |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

● Video Introduction

● Machine Features

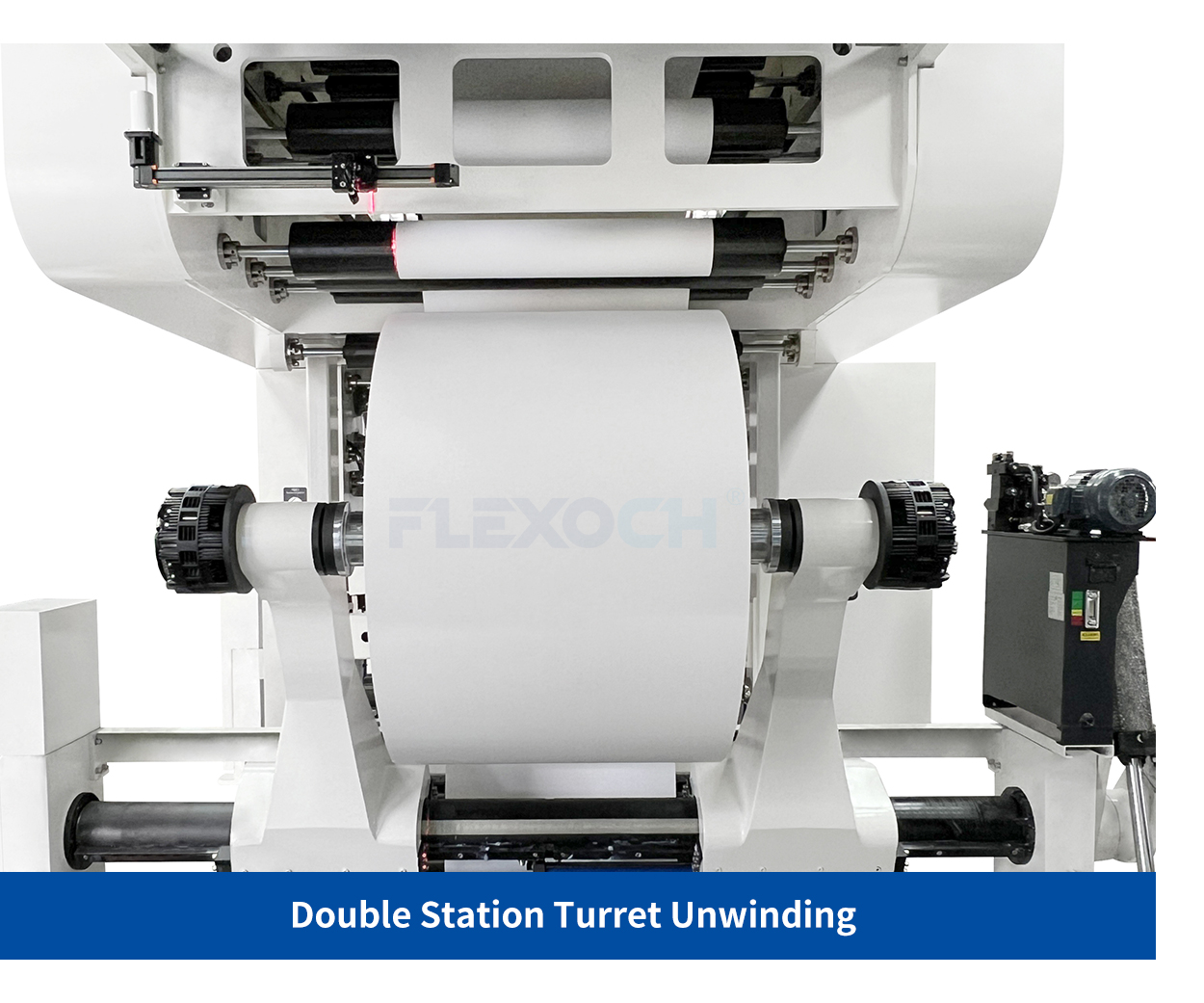

1.This Gearless Flexo Printing Press adopts advanced gearless servo drive technology, eliminating errors from traditional gear transmission to ensure printing accuracy and stability. With faster speeds and more precise registration, it significantly enhances production efficiency. The dual-position non-stop roll-changing system enables automatic material splicing during high-speed operation, boosting productivity and meeting the demands of large-volume continuous production.

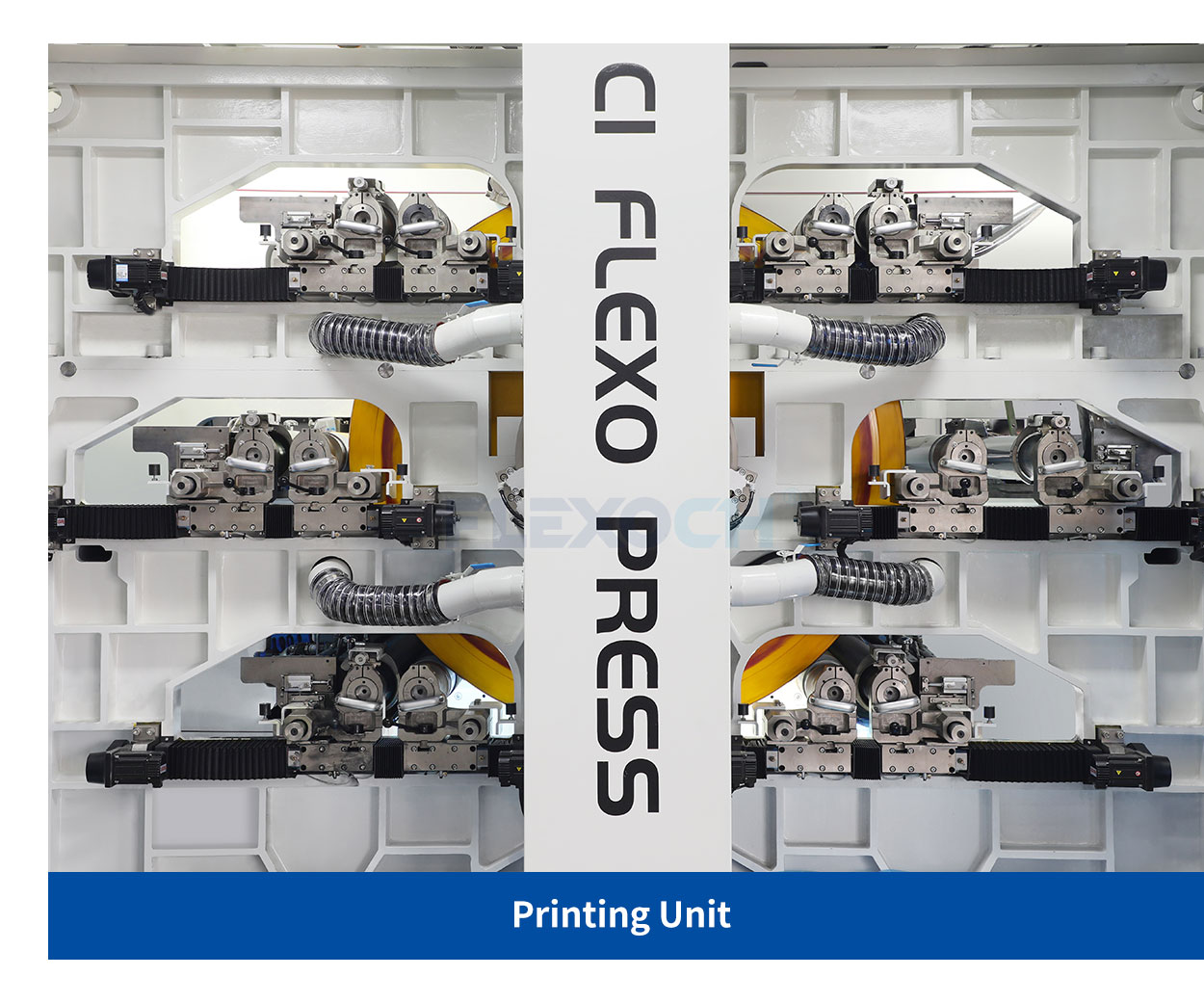

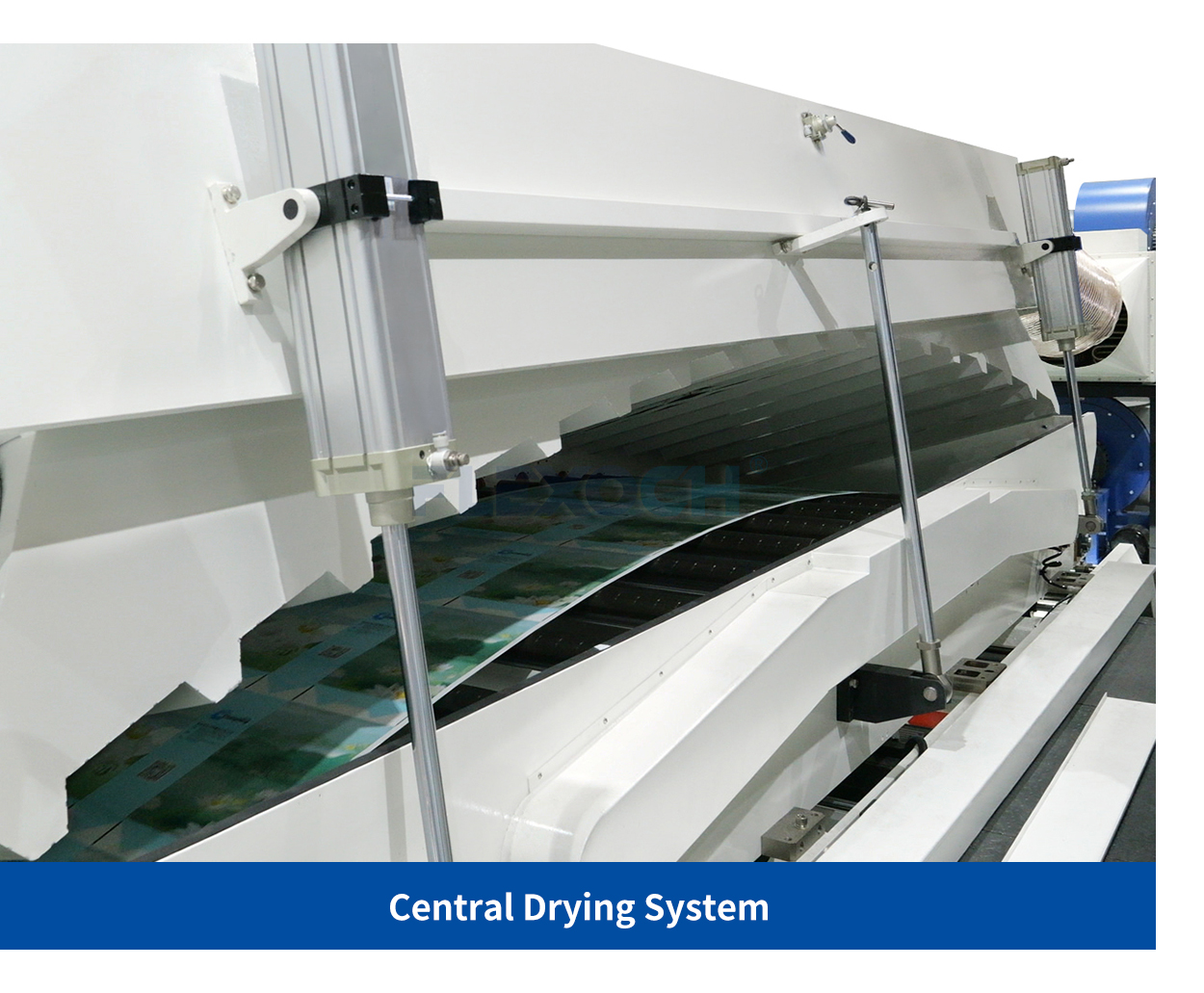

2.Optimized for paper, non-woven fabrics, and other substrates, this Gearless Cl Flexo Press is ideal for food packaging, medical supplies, eco-friendly bags, and other versatile printing applications. Its modular design allows rapid plate and color changeovers, while the intelligent registration system ensures high-precision six-color alignment, delivering sharp patterns and vibrant colors.

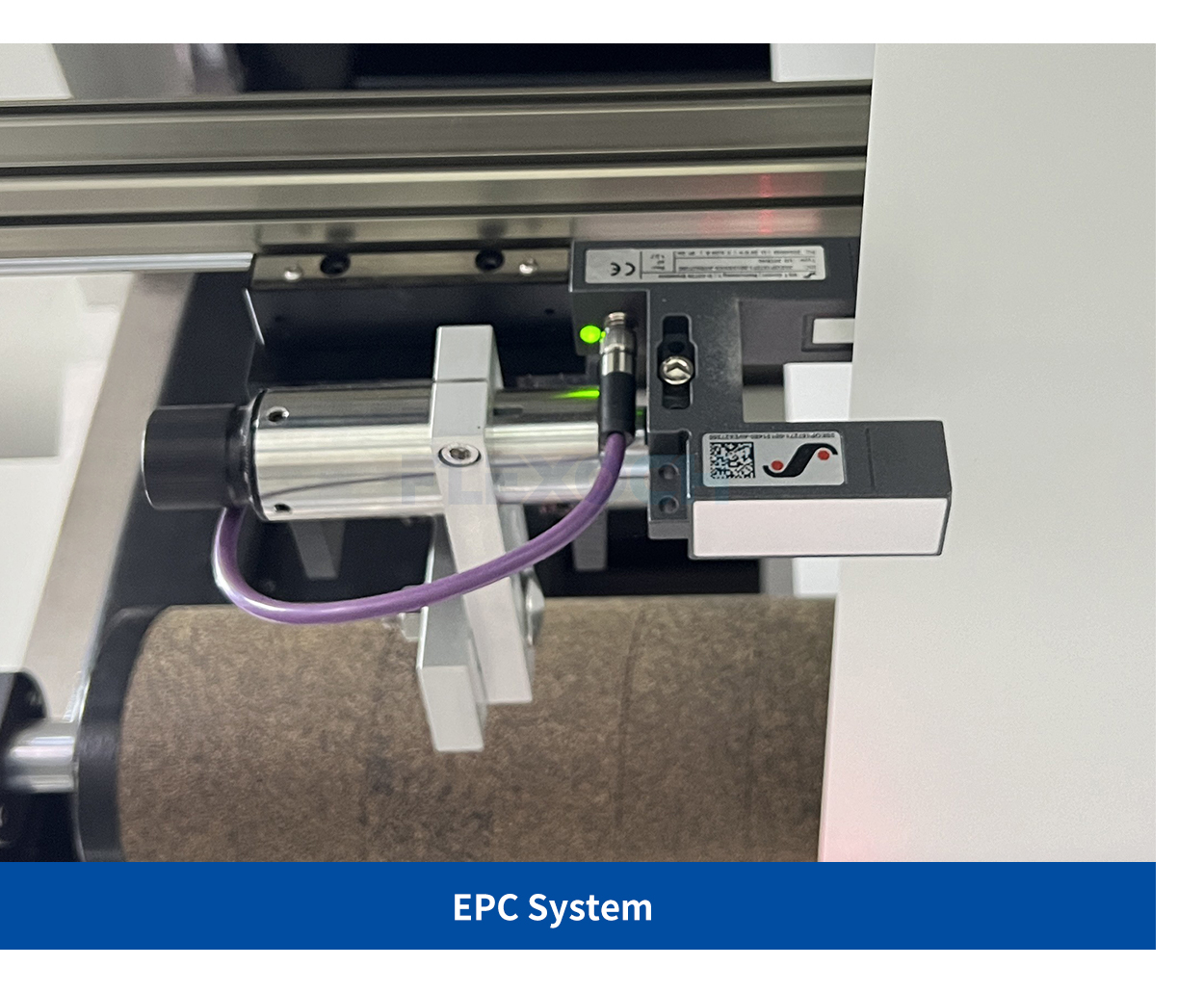

3.Equipped with an advanced human-machine interface and automated control system, this press monitors printing parameters in real time and automatically adjusts key parameters such as tension and registration, minimizing manual intervention and simplifying operation, while improving print quality consistency. It also supports environmentally friendly materials such as water-based inks, aligning with green production trends.

4. Servo-driven flexographic printing machines significantly reduce mechanical friction losses, resulting in lower energy consumption. Key components utilize a modular structure, enabling rapid troubleshooting and low maintenance costs. Flexible printing unit configurations can be upgraded and expanded based on customer needs, adapting to future process adjustments.

● Details Dispaly

● Printing Samples

Post time: Aug-13-2025