The newly launched 6 color CI central impression flexo printing machine is designed for flexible packaging materials (such as plastic films). It adopts advanced central impression (CI) technology to ensure high-precision registration and stable printing quality, which is suitable for large-scale production needs. The equipment is equipped with 6 printing units and supports efficient multi-color printing, which is suitable for fine patterns and complex color requirements.

● Technical Specifications

|

Model |

CHCI6-600J-S |

CHCI6-800J-S |

CHCI6-1000J-S |

CHCI6-1200J-S |

|

Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

250m/min |

|||

|

Max. Printing Speed |

200m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1000mm/Φ1200mm |

|||

|

Drive Type |

Central drum with Gear drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

● Video Introduction

● Machine Features

1.High-Precision Overprinting, Exceptional Print Quality:This ci flexographic press features advanced Central Impression (CI) technology, ensuring precise alignment of all color units and minimizing deviations caused by material stretching or misregistration. Even at high speeds, it delivers sharp, clear prints, effortlessly meeting the stringent quality demands of high-end flexible packaging for color consistency and fine detail reproduction.

2. Servo-Driven Unwinding/Rewinding for Precise Tension Control

This Economic srvo Ci flexo printing machine employs high-performance servo motors for unwinding and rewinding, integrated with a fully automatic tension control system. It ensures consistent material tension even at high speeds, preventing film stretching, distortion, or wrinkling—ideal for precision printing on ultra-thin films and sensitive substrates.

3.Versatile Multi-Color Printing for Complex Designs:The flexographic printing equipment with 6 independent printing units, it supports full-color gamut overprinting, completing multi-color jobs in a single pass to minimize plate-changing waste. Integrated with a smart color management system, it accurately reproduces spot colors and intricate gradients, empowering clients to realize creative packaging designs and leverage the advantages of flexographic multi-color printing.

4.High Efficiency & Stability for Mass Production:Optimized for continuous high-speed printing, the central impression flexo printing machine operates smoothly, significantly reducing downtime from registration adjustments or mechanical vibrations. Its robust construction and intelligent control system ensure long-term stable output, making it ideal for large-volume orders in industries like food, and household chemicals.

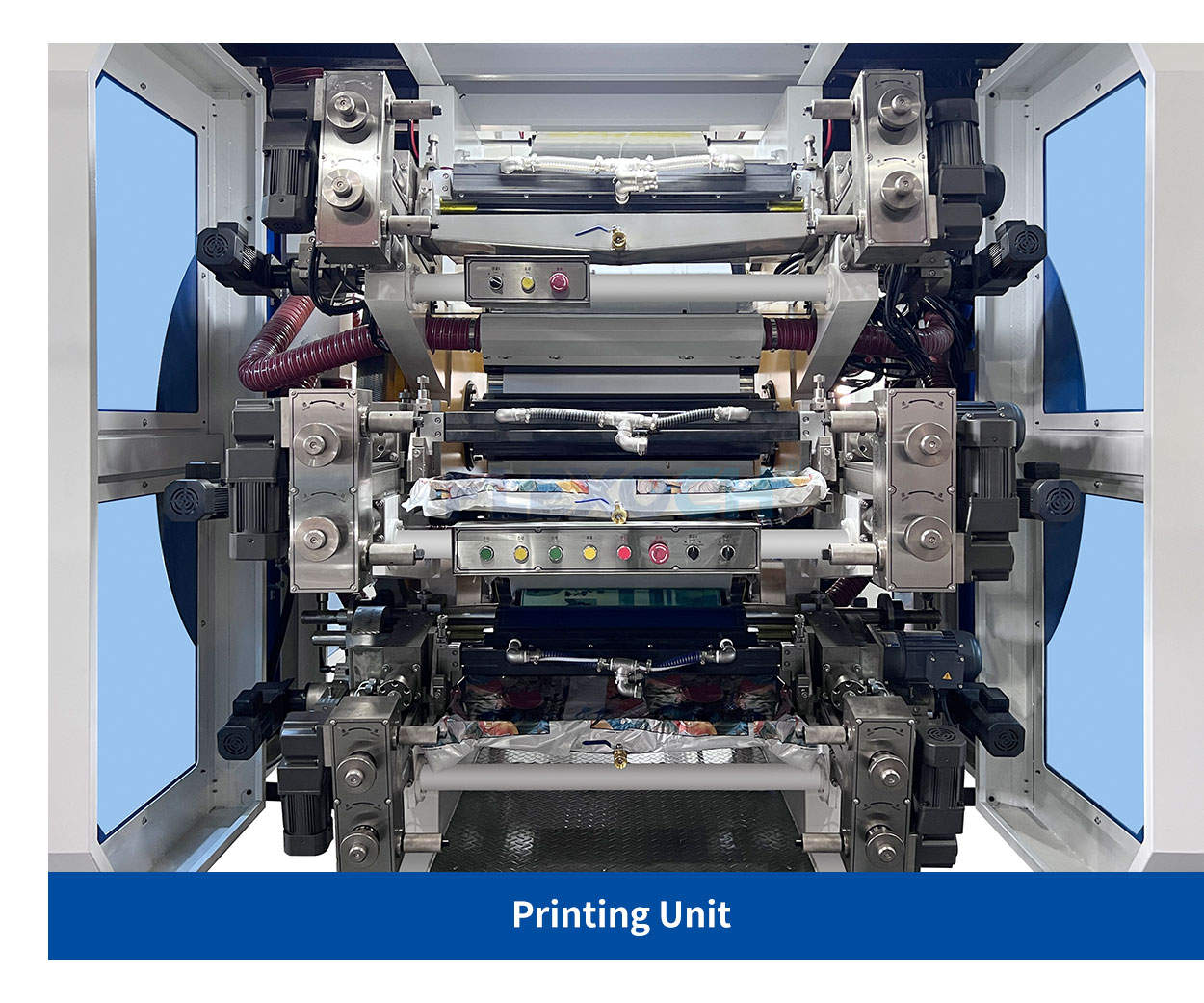

● Details Dispaly

● Printing Samples

Post time: Aug-21-2025