In the packaging and printing industry, stack flexo printing machines have become a core asset for many enterprises due to their flexibility and efficiency. Their ability to work with different substrates and adapt to a range of production volumes has made them a go-to choice for many factories looking to stay competitive. But in a market where delivery timelines keep shrinking and quality standards only go up, buying advanced machines is no longer enough. The real pressure now sits squarely on improving productivity—avoiding unnecessary downtime, keeping print quality consistent, and squeezing as much output as possible from every production shift.None of this can be achieved by relying on one single change; it calls for a coordinated effort across workflow planning, equipment management and operator capability.

Equipment maintenance: the backbone of stable production

For stack-type flexo printers, stability and precision make or break your productivity. Sticking to regular maintenance is what keeps them running reliably and performing well long-term.Case in point: check gears, bearings, and other key parts for wear. Swap out old, worn components on time, and you’ll avoid unexpected breakdowns that shut down production. Also, tweaking printing pressure, tension, and registration the right way cuts down on waste and makes your output quality sharper. Using good-quality printing plates and anilox rollers helps too—they boost how well ink transfers, so you get better speed and better results.

Process optimization: the engine driving real efficiency gains

In flexographic production, efficiency is rarely determined by a single factor. A stack type flexo printing machine involves a network of interacting variables—ink viscosity, printing pressure, tension control, drying performance, and more. A slight imbalance in any of these areas can slow down the entire production line. . Streamlining setup procedures and minimizing changeover time can deliver immediate results.For instance, employing preset parameter technology—where printing settings for different products are stored in the system and recalled with a single click during order changes—dramatically reduces preparation time.

Operator proficiency directly impacts production efficiency.

Even the fanciest stack flexo printer can’t reach its full potential without skilled workers running it. Regular training helps employees get to know the machine’s capabilities, how to fix common issues, and how to switch jobs quickly—this cuts down on human mistakes and delays from wrong operations.The operators who really know their way around the equipment can pick up on small changes during runs: a little shift in tension, how the ink’s laying down, or early signs that something’s off. They’ll jump in fast before a tiny problem shuts down production.Setting up incentive programs to encourage workers to tweak processes and come up with their own improvements builds a culture of always getting better—and that’s key for keeping efficiency up over the long haul.

● Video Introduction

Smart upgrades represent the future trend

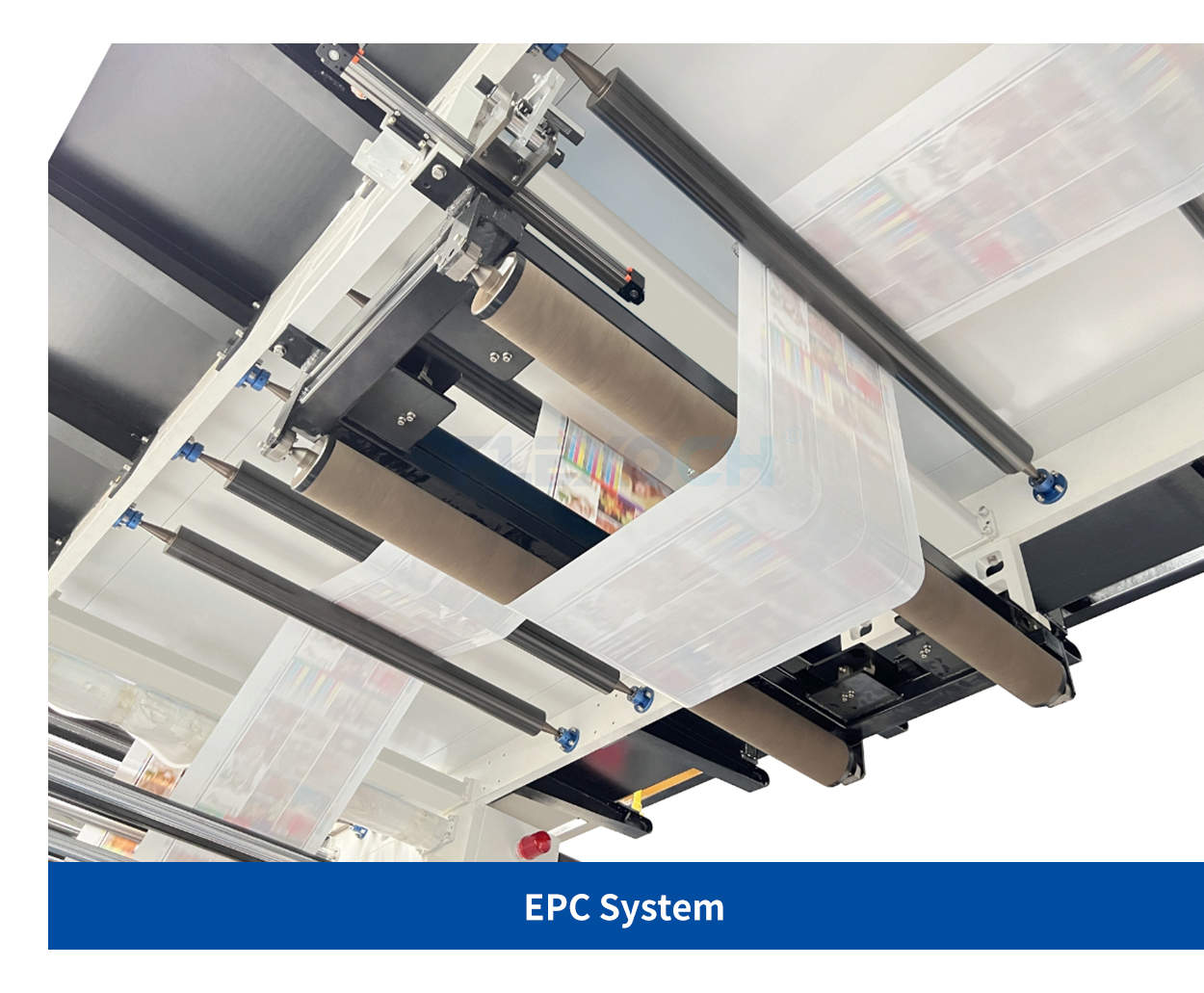

As the industry transitions toward Industry 4.0, intelligent automation is becoming the next competitive differentiator. Integrating systems such as automatic registration control, inline defect detection, and data-driven process dashboards into flexo stack press dramatically reduces manual intervention while improving print precision and production stability. Inline inspection systems today are much sharper than they used to be. They match each print against a reference image in real time and call out problems before they turn into a stack of wasted material. Updates like this may seem small, but they’re changing the rhythm of daily production—lines run steadier, issues get handled faster, and quality holds up without constant firefighting.

Scientific production scheduling: a critical yet often overlooked advantage

Amid the push for smarter equipment and tighter process control, production scheduling frequently receives less attention than it deserves. In reality, when product variety grows and delivery timelines shrink, poorly coordinated scheduling can quietly drain productivity—even in facilities equipped with advanced machinery.Strategic planning based on order urgency, job complexity, and the real-time status of each flexo stack press enables manufacturers to reduce disruptive changeovers and preserve production stability.

Equally important is having a smart and disciplined approach to material management. You’ll want to keep a steady supply of inks, substrates, printing plates, and semi-finished goods on hand—this way, production won’t grind to a halt just because something runs out at the worst possible time.If materials show up right when you need them—no early stockpiling, no last-minute shortages—your workflow stays smooth. The press keeps rolling instead of sitting idle waiting for supplies, and downtime drops a lot.A lot of the time, you can boost overall output without buying any new equipment. It’s just about better planning and closer teamwork between purchasing, warehousing, and production.

Post time: Jul-10-2025