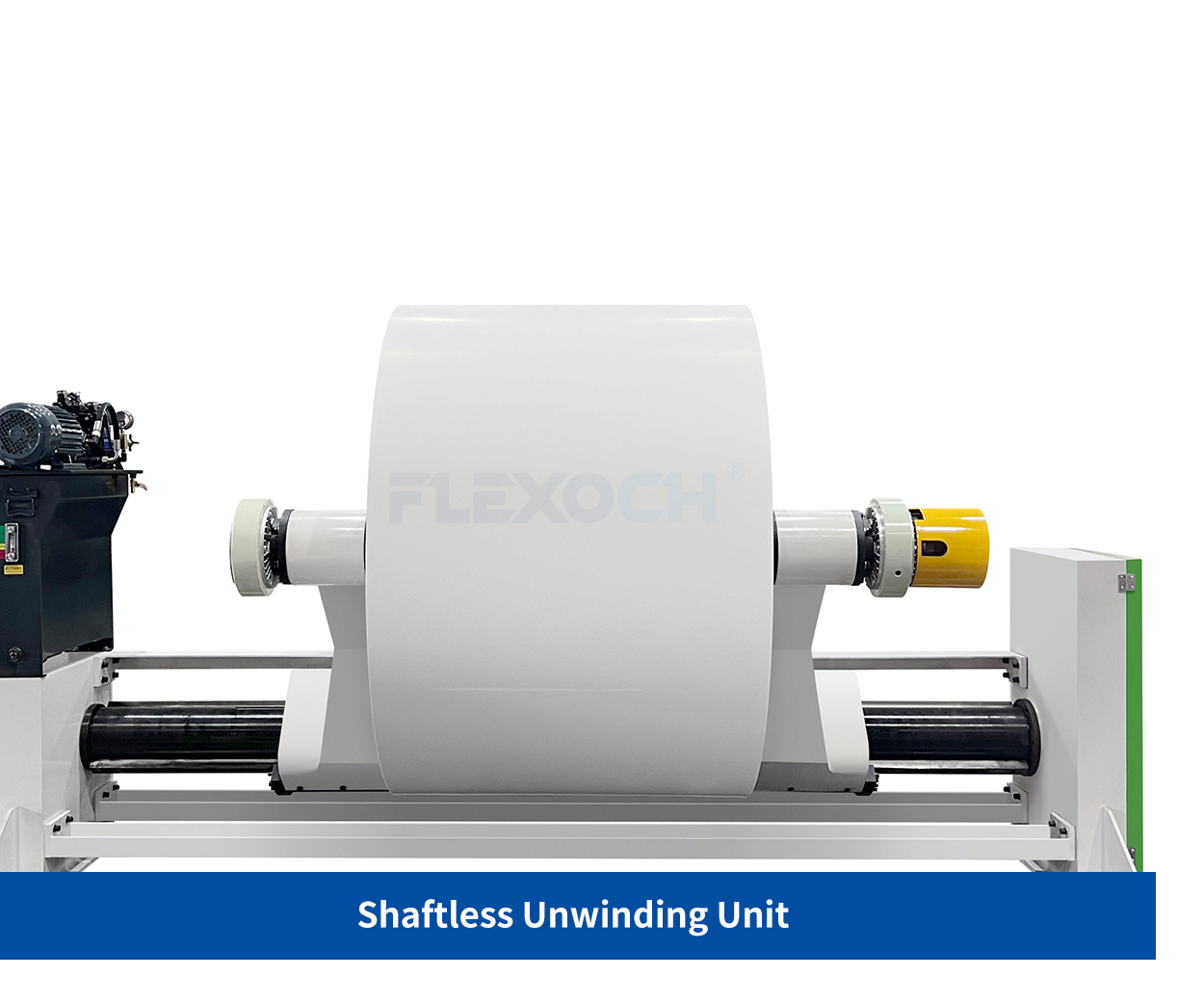

This high-performance six colour central impression flexo press adopts advanced shaftlessunwinding and central impression(ci)technology. The equipment supports printing widths ranging from 600mm to 1200mm, with a maximum speed of up to 200m/min,making it ideal for high-quality,large-volume printing of paper cups and flexible packaging.

●Technical Specifications

| Model | CHCI6-600J-Z | CHCI6-800J-Z | CHCI6-1000J-Z | CHCI6-1200J-Z |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max. Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia. | Φ1200mm/Φ1500mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | Paper、Non Woven、Paper Cup | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

●Video Introuction

●Machine Features

Excellent Efficiency, Soaring Productivity with CI Flexo:

The shaftless unwinding technology enables continuous, non-stop production, completely eliminating downtime for roll changes. Combined with a printing speed of 200 m/min, it significantly enhances equipment utilization and overall output efficiency, meeting the rapid delivery demands of large-volume orders.

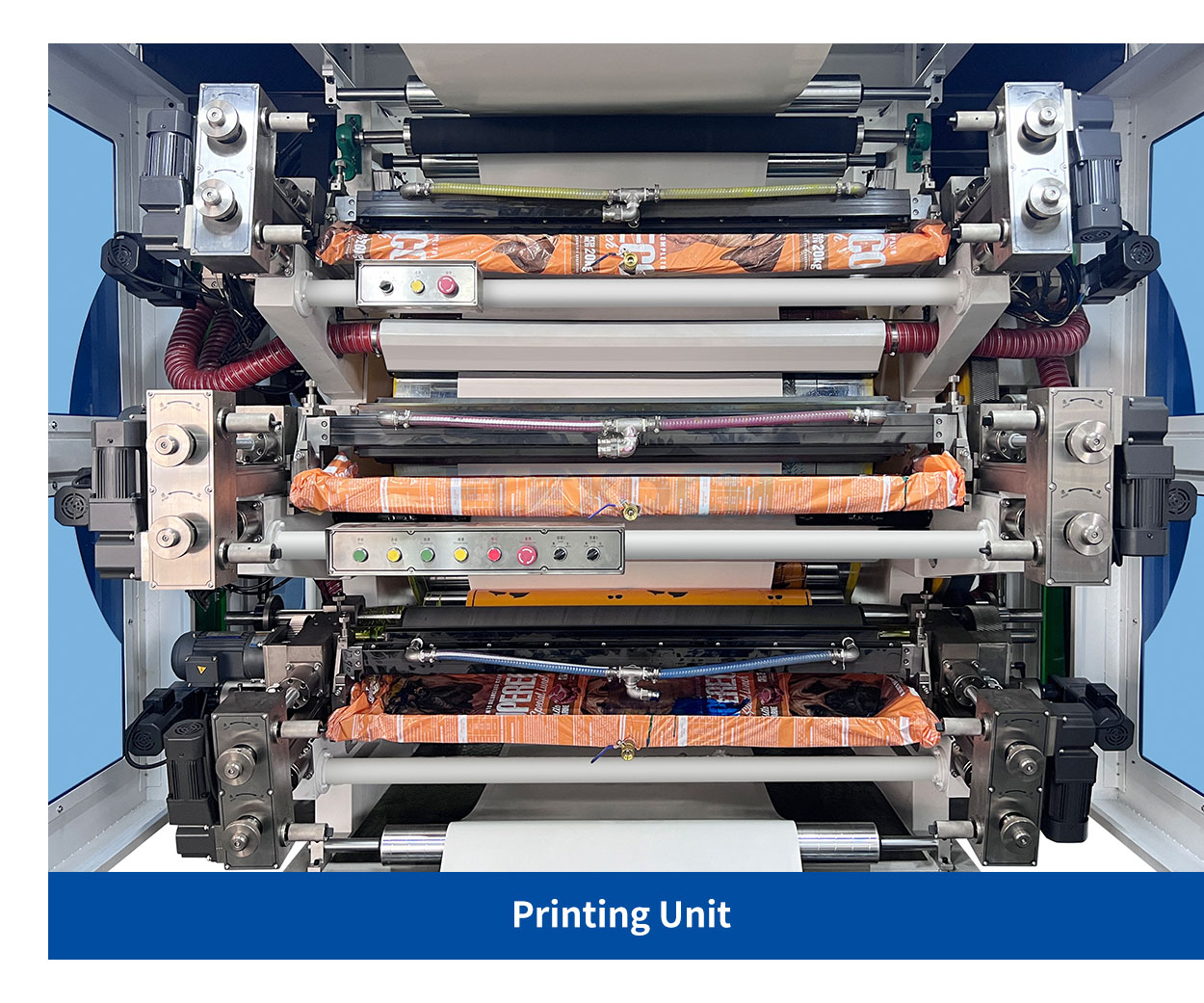

Flawless Printing, Precision and Brilliance:

The unique central impression flexo press structure ensures all printing units operate around a shared drum, perfectly avoiding ghosting and misalignment issues. With 6 color flexo printing capability and eco-friendly inks, it accurately reproduces intricate patterns and fine gradients, delivering vibrant, rich surfaces and superior tactile quality for premium printing results.

CI Flexo Press: Cost-Effective Performance:

The shaftless unwinding system’s continuous production and the central impression flexo printing machine structure’s high precision significantly reduce material waste during setup, roll splicing, and registration adjustments. High automation and stability minimize manual intervention and unplanned downtime, improving production economics.

Versatile Adaptability, Effortless Performance:

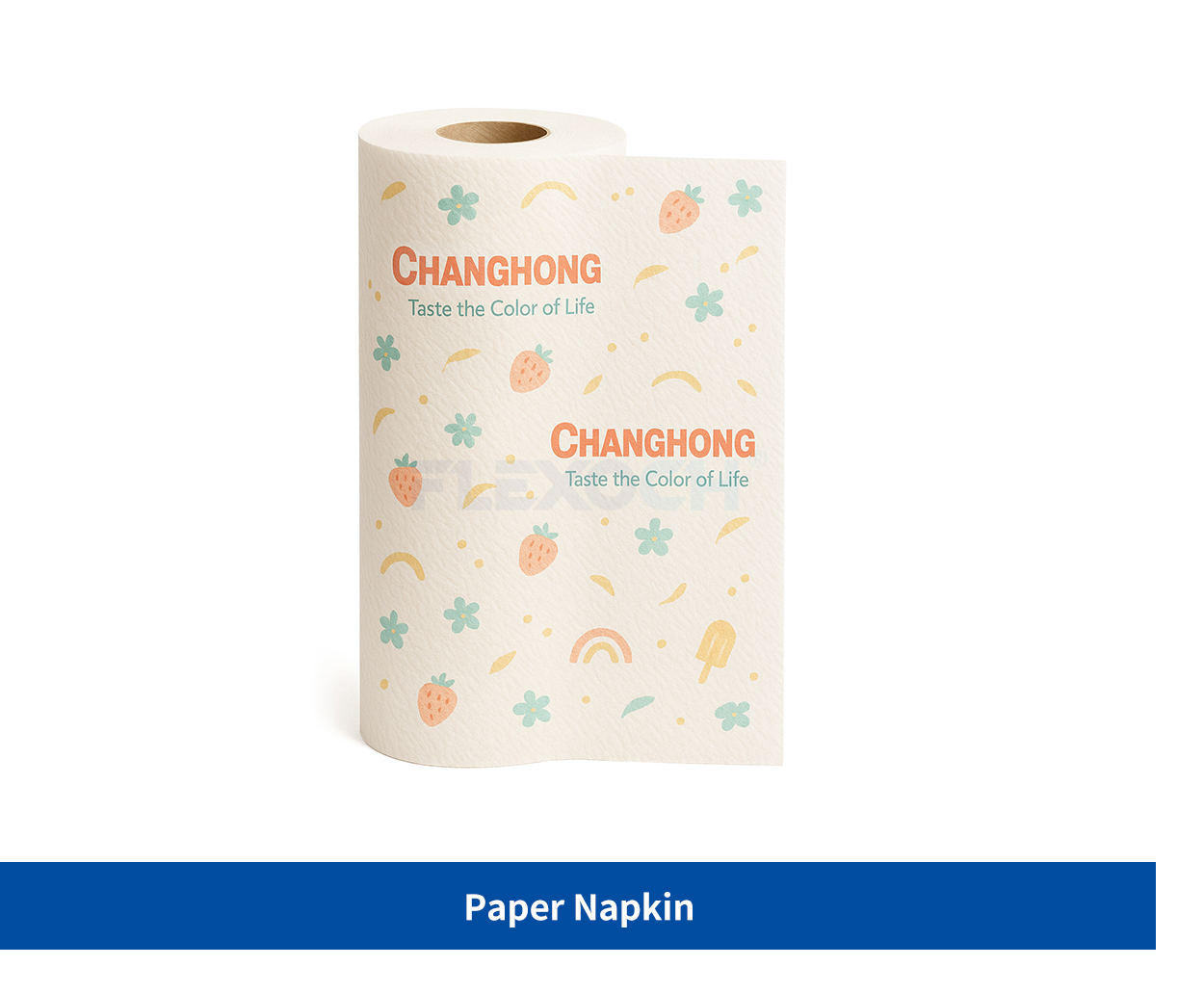

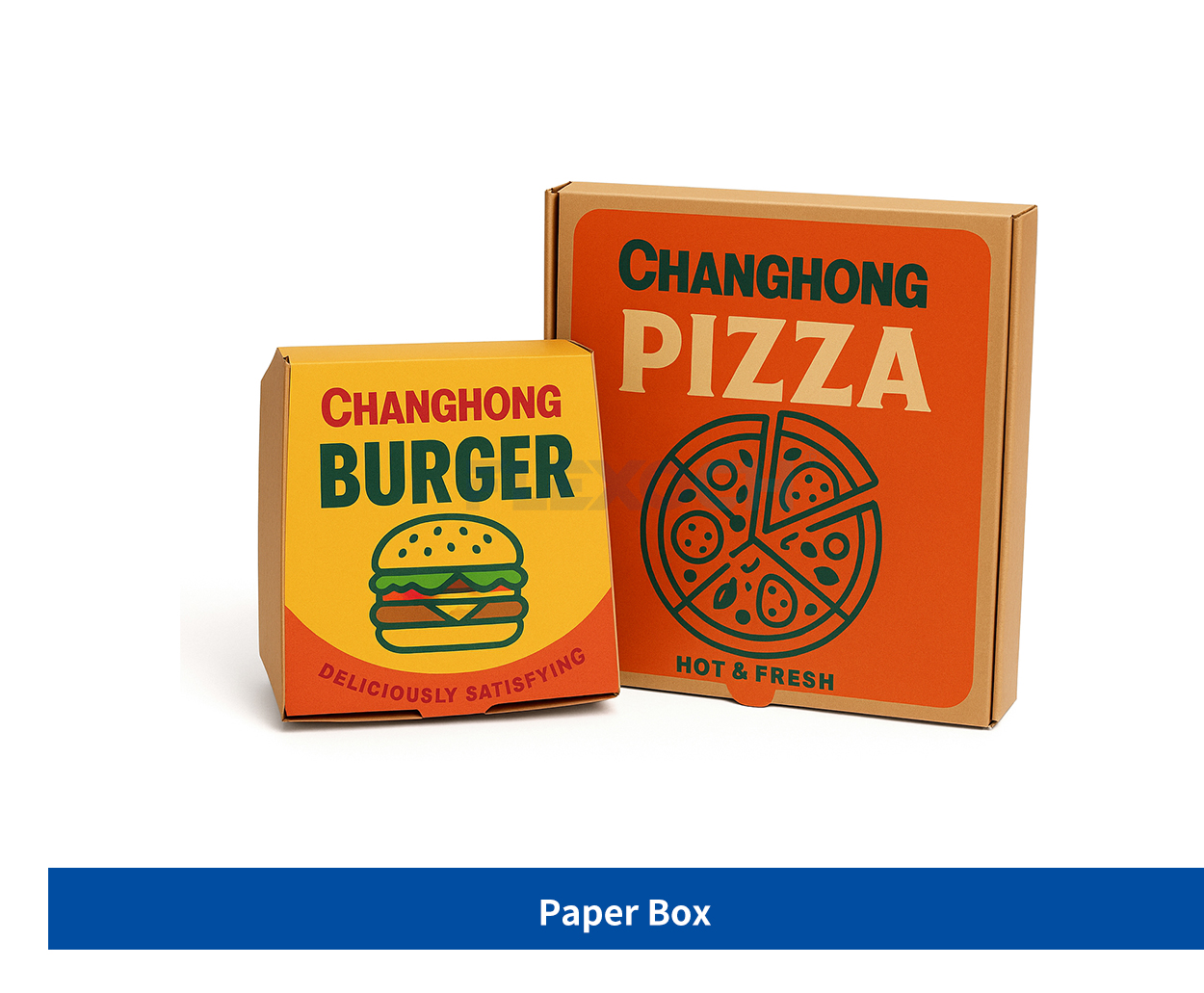

Offering multiple mainstream width options, the ci flexo press efficiently accommodates different paper cup sizes while easily supporting common substrates like paper and non-woven fabrics. Quick plate changes in flexographic printing, along with automated functions, shorten product switchover times, enabling fast responses to diverse, high-volume orders. Certified for food-safe packaging, this durm flexo printing machine is the ideal solution for paper cup manufacturing.

●Details Dispaly

●Printing Sample

Post time: Jul-25-2025