Selecting the right wide-web CI flexo printing machines requires careful consideration of several key parameters to ensure optimal performance and efficiency.One of the most critical factors is the printing width, which determines the maximum web width the flexo press can handle. This directly impacts the types of products you can produce, whether flexible packaging, labels, or other materials. Printing speed is equally important, as higher speeds can significantly boost productivity but must be balanced with precision and print quality. Additionally, the number of printing stations and the ability to add or modify stations for different colors or finishes can greatly enhance the machine's versatility, enabling more complex designs and specialized applications.

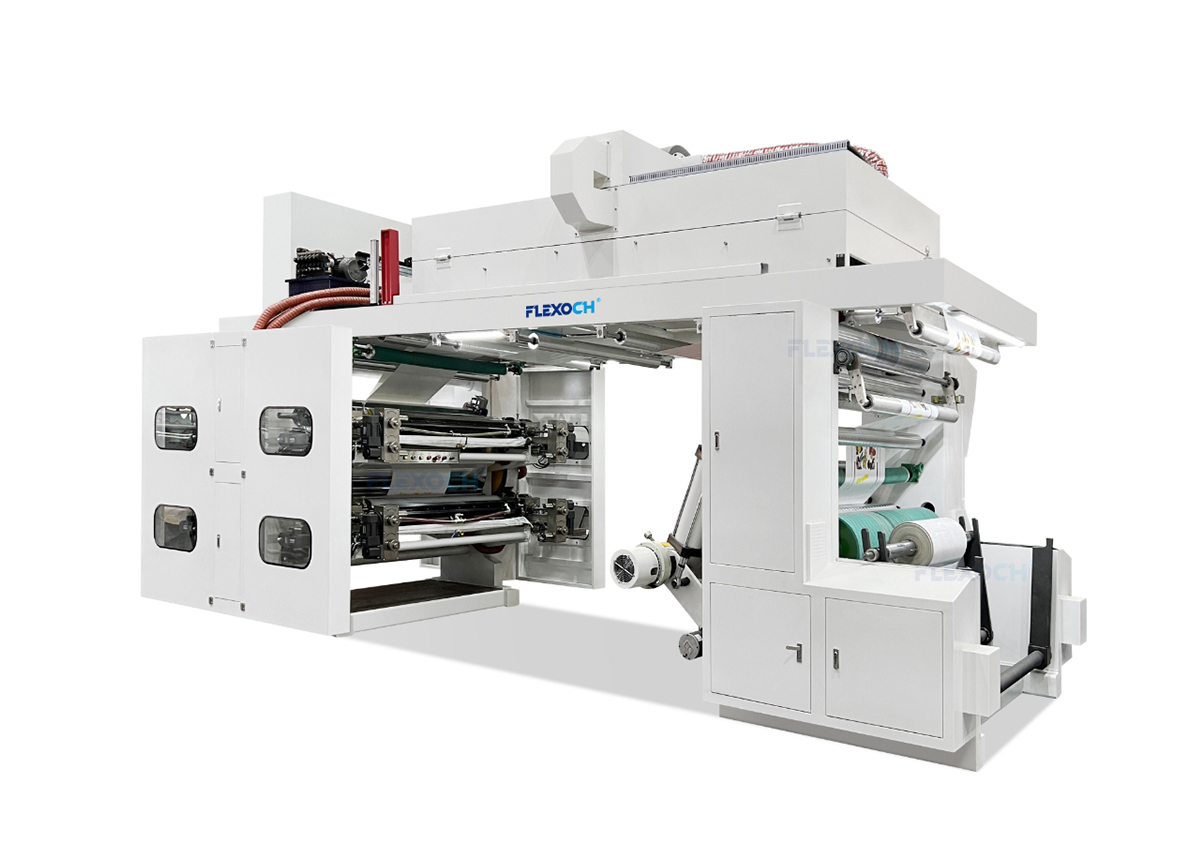

These are the technical specifications of our ci flexo printing machine.

| Model | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Web Width | 700mm | 900mm | 1100mm | 1300mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 350m/min | |||

| Max. Printing Speed | 300m/min | |||

| Max. Unwind/Rewind Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink olvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP,OPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V.50 HZ.3PH or to be specified | |||

Another crucial aspect is the register accuracy of the flexographic press. Our central impression flexo press offers a register accuracy of ±0.1 mm, ensuring perfect alignment of each color layer during printing. Advanced systems equipped with automatic register control minimize waste and reduce setup time. The type of ink system—water-based, solvent-based, or UV-curable—also plays a vital role, as it affects drying speed, adhesion, and environmental compliance. Equally important is the drying or curing mechanism, which must be efficient to prevent smudging and ensure consistent output, especially at high speeds.

● Video Introduction

Lastly, the overall build quality and level of automation in the central impression flexo press should align with your production needs. A robust frame and high-quality components enhance durability and reduce downtime, while features like automatic tension control and web guiding systems improve operational efficiency.Sustainable energy use and low-maintenance designs further contribute to cost-effectiveness over the machine’s lifecycle. By thoroughly evaluating these parameters, you can choose a ci flexo printing machine that not only meets your current needs but also adapts to future challenges in the rapidly evolving printing industry

Post time: Apr-29-2025