In the field of high-end flexographic printing press manufacturing, precision and reliability are not accidental but stem from the meticulous control of every detail. From micrometer-level calibration of core components to comprehensive performance testing of the entire machine, we ensure that every unit delivered exhibits stable, accurate, and durable excellence, meeting zero-defect standards.

The Battle for Mechanical Precision in Fractions of a Millimeter

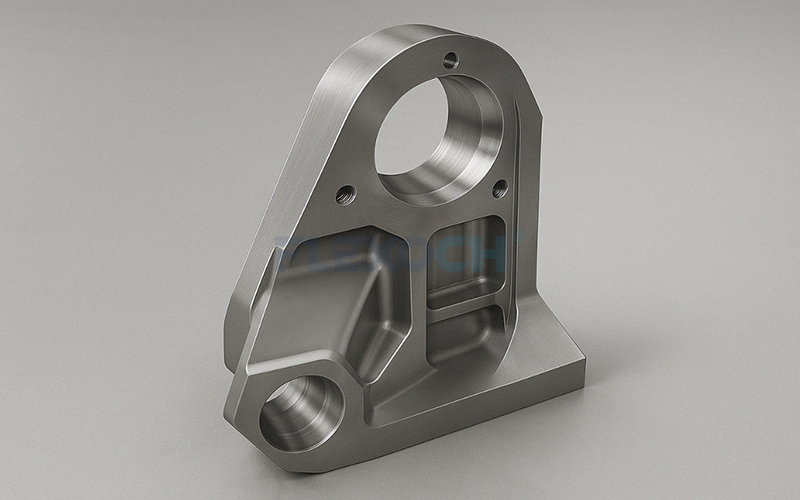

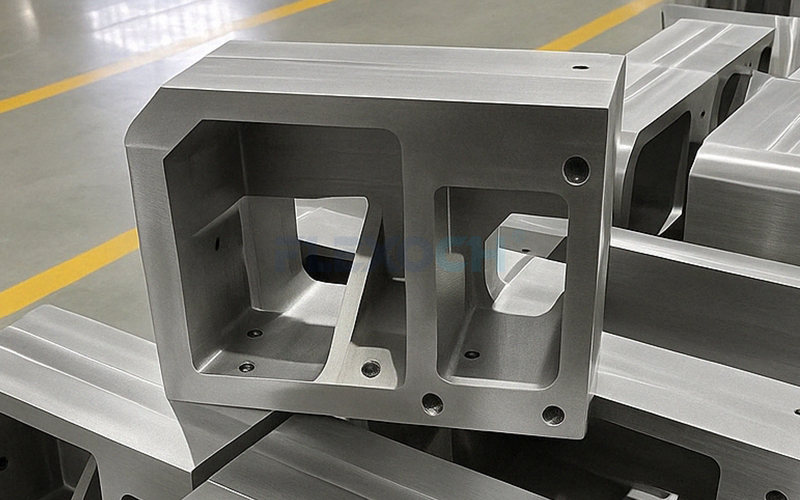

In flexographic printing press manufacturing, the key to long-term stable operation lies in the precise coordination of mechanical structures. We understand that true reliability begins with extreme control over the smallest details—from the exact torque applied to every screw to micrometer-level verification of gear meshing gaps using laser distance measurement. We build the foundation of quality with near-rigorous standards.

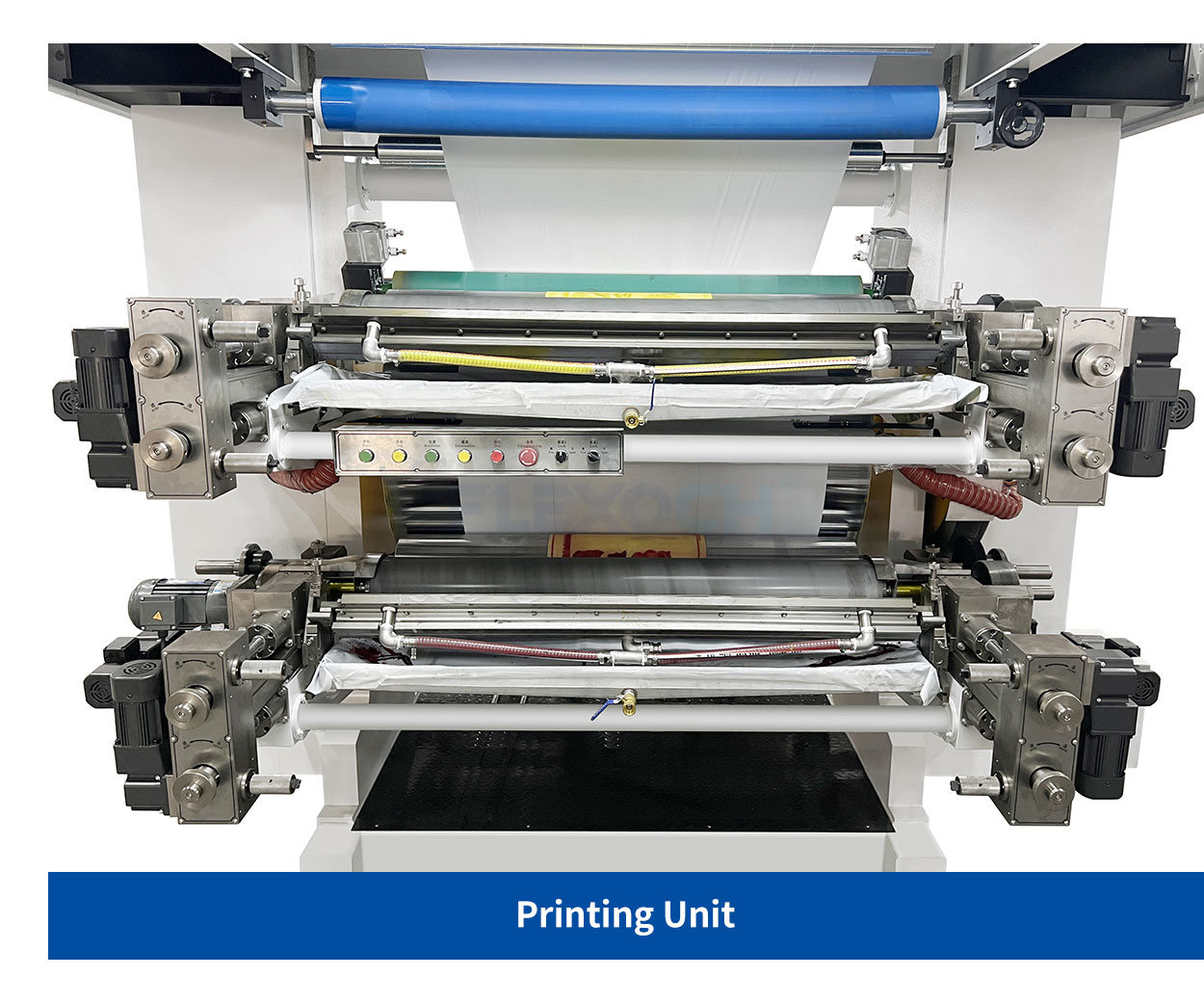

We employ high-precision laser calibration systems for comprehensive dynamic testing of the flexo printing machine’s transmission system, ensuring that core parameters such as gear meshing, bearing clearance, and guide rail parallelism remain in optimal condition. Particularly during load testing simulating high-speed printing, engineers continuously monitor the equipment’s vibration suppression performance under prolonged operation. Through real-time data collection and analysis, we strictly control roller vibration amplitude within 0.01mm, eliminating risks of misregistration or mechanical wear caused by minute deviations.

Stable Assurance of Printing Performance

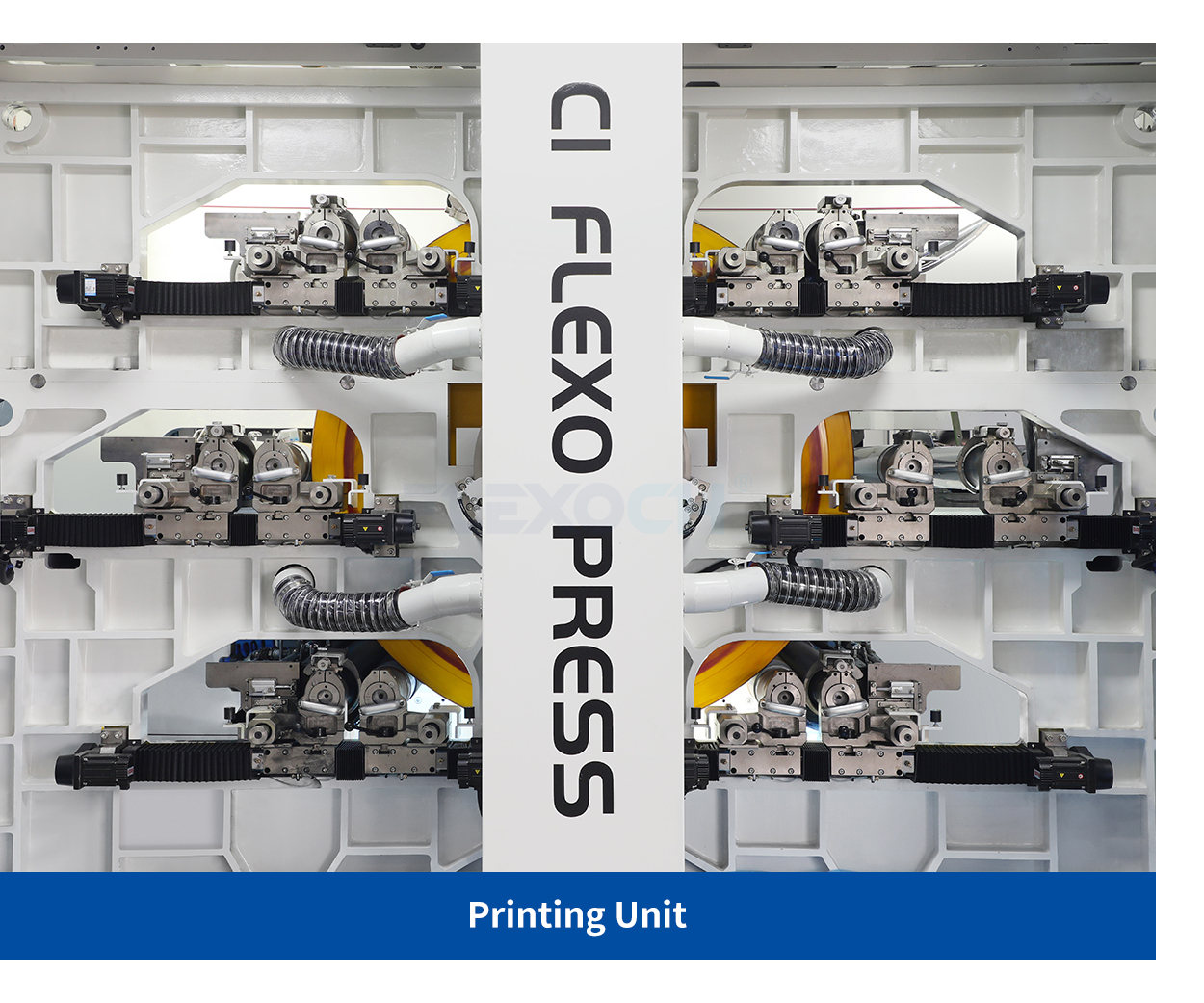

The stability of the flexo printing machine’s printing unit directly determines output quality. Changhong utilizes high-resolution CCD vision systems to monitor dot reproduction in real time, combined with automatic closed-loop adjustment technology, ensuring uniform ink color and precise registration. Additionally, for different substrates (such as film, paper, and composite materials), our workshop conducts adaptive testing under simulated real-world production conditions to guarantee outstanding print consistency across various operating scenarios.

Reliability Verification of Intelligent Control Systems

As modern machine impression flexo become increasingly intelligent, the stability of electrical systems is critical. Changhong’s testing process includes in-depth validation of core modules such as servo drives and tension control. By simulating abnormal conditions like sudden power outages or signal interference, we evaluate the flexo printing equipment’s rapid recovery capability and anti-interference performance. Furthermore, every unit undergoes a 48-hour continuous production simulation test before leaving the factory, ensuring stable performance even under prolonged high-load operation.

Ultimate Testing Under Harsh Conditions

True quality must withstand extreme challenges. Changhong’s testing system not only focuses on performance under standard conditions but also conducts environmental adaptability tests in high-temperature, high-humidity, and dusty conditions, ensuring stable operation across different regions and seasonal production environments.

From the tightening torque of a single screw to the dynamic balance of the entire flexo printing machine; from the accuracy of a single print to the durability of long-term operation—every step of Changhong’s inspection process embodies the manufacturing philosophy of "zero defects." We know that only an uncompromising pursuit of quality can give customers a worry-free production line.

Post time: Jun-24-2025