A brand-new high-speed wide web dual-station non-stop unwinding/rewinding roll-to-roll 8 olor flexographic ci printing machine, specifically designed for plastic film printing. Utilizing central impression cylinder technology to ensure high precision and efficient production. Equipped with advanced automated control and a stable tension system, this machine meets the demands of high-speed continuous printing, significantly enhancing production efficiency.

● Technical Specifications

|

Model |

CHCI8-600E-S |

CHCI8-800E-S |

CHCI8-1000E-S |

CHCI8-1200E-S |

|

Max. Web Width |

700mm |

900mm |

1100mm |

1300mm |

|

Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

|

Max. Machine Speed |

350m/min |

|||

|

Max. Printing Speed |

300m/min |

|||

|

Max. Unwind/Rewind Dia. |

Φ800mm/Φ1000mm/Φ1200mm |

|||

|

Drive Type |

Central drum with Gear drive |

|||

|

Photopolymer Plate |

To be specified |

|||

|

Ink |

Water base ink or solvent ink |

|||

|

Printing Length (repeat) |

350mm-900mm |

|||

|

Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, |

|||

|

Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

|||

● Video Introduction

● Machine Features

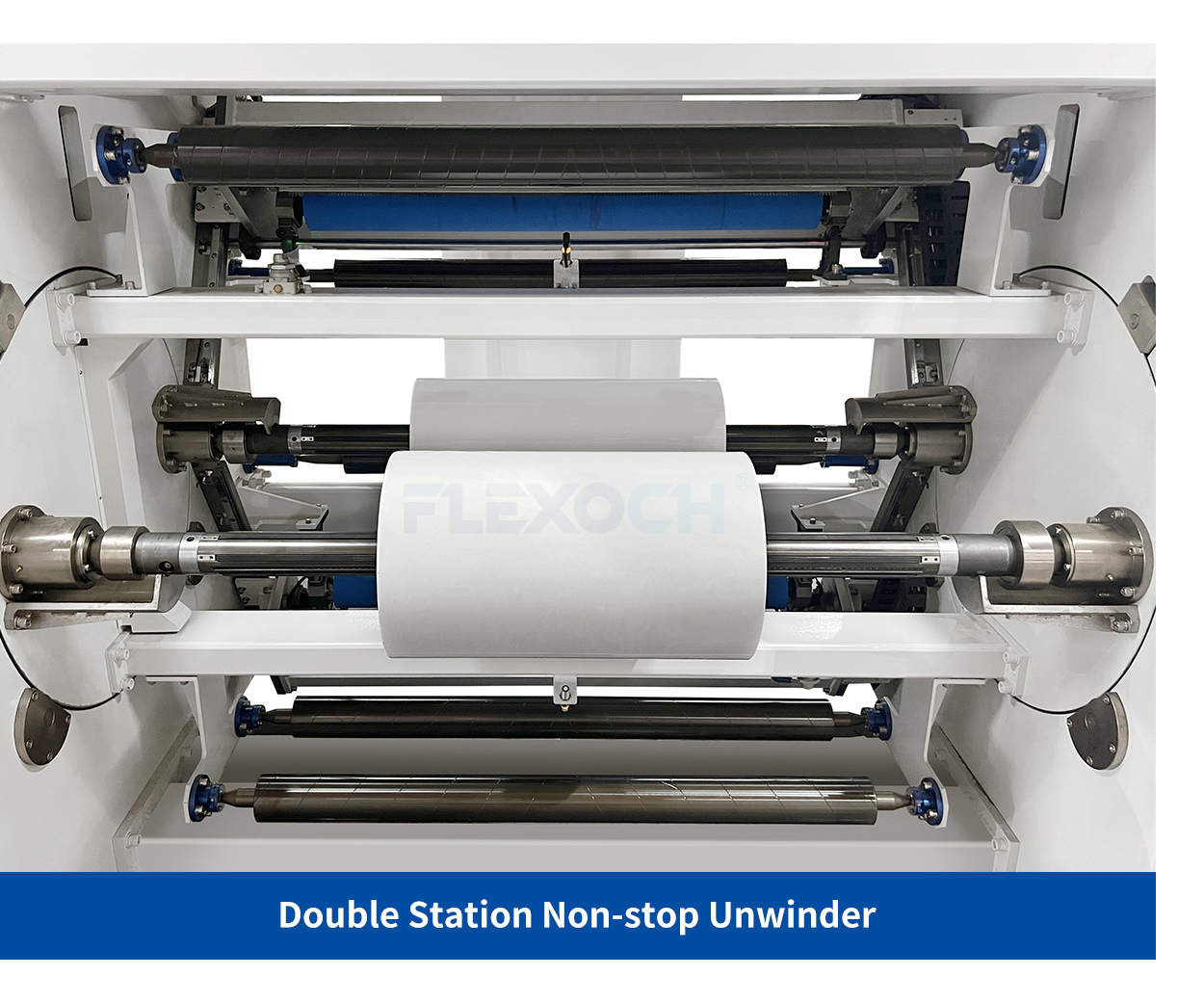

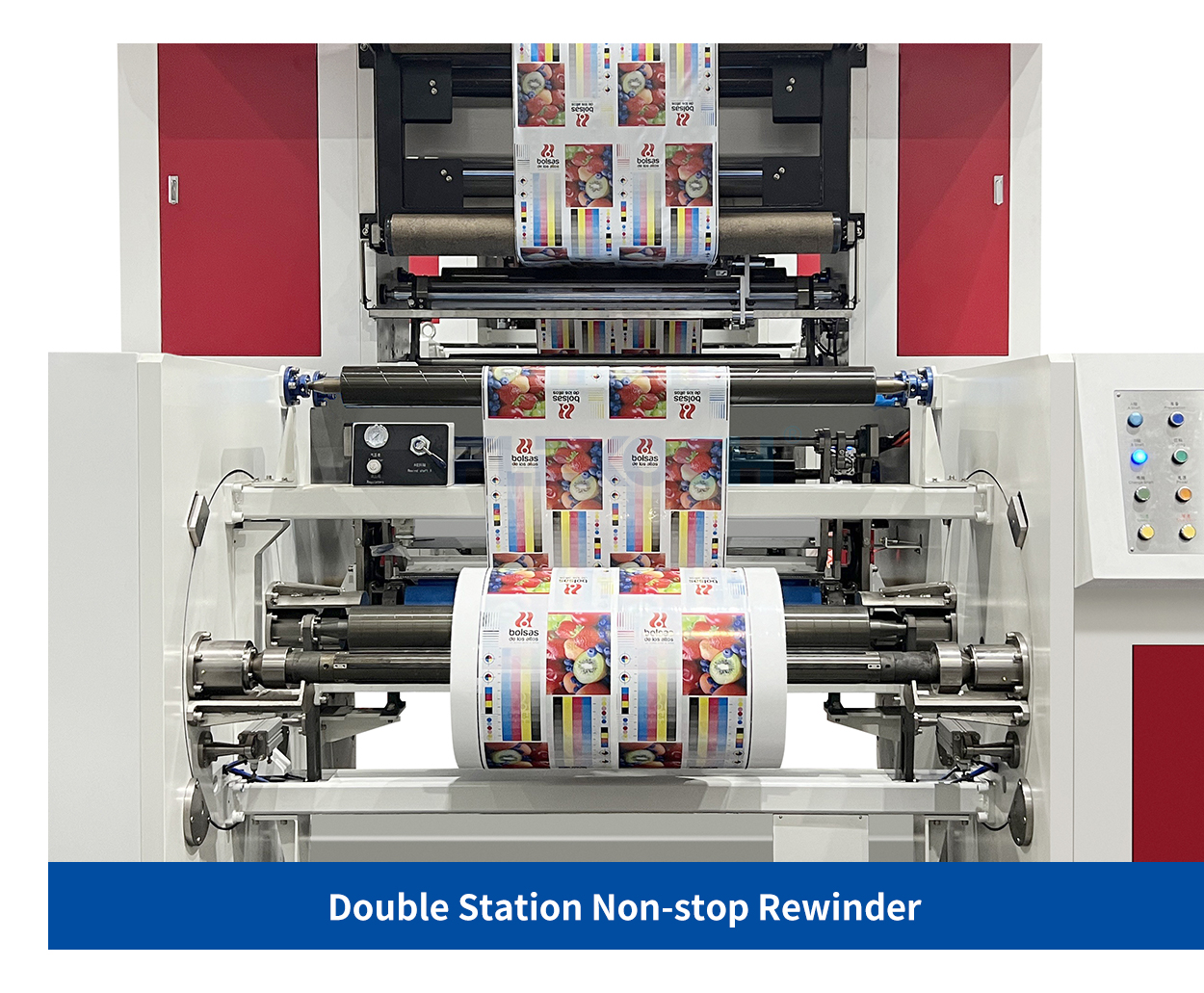

1.High-Efficiency Continuous Production Without Downtime:

This ci printing machine features a unique dual-station unwind/rewind system, enabling automatic roll changes during high-speed operation. This eliminates the traditional limitation of requiring machine shutdown for roll changes. Innovative mechanical design, combined with a precision tension control system, ensures a smooth and stable roll changeover, minimizing material waste to the greatest extent. This significantly enhances the market competitiveness of packaging printing enterprises.

2.Consistent High Print Quality:The CI printing machine utilizes a Central Impression (CI) cylinder structure coupled with a precision gear drive system, ensures registration accuracy within ±0.1 mm across all color units. An optimized ink delivery system and pressure adjustment devices guarantee sharp, full dots and uniform, consistent color reproduction. The specially engineered drying system accommodates various ink types, ensuring consistent, high-quality printed output.

3.Advanced Control System Enhances User Experience:The ci flexo printing machine is equipped with a professional control system, operators can monitor print quality in real-time via high-resolution video. An intuitive control interface simplifies the parameter setup process, with key production data clearly displayed. Comprehensive fault diagnosis functions aid in rapid problem identification, significantly boosting production efficiency.

4.Flexible Configuration for Diverse Needs:

Featuring a modular architecture, this ci flexo press allows for flexible combinations of 4 to 8 printing units, enabling quick changeovers between different printing jobs. Its robust mechanical design handles a wide range of plastic films from 10 to 150 microns, including PE, PP, PET, and others. It delivers exceptional print results for both simple text and complex multi-color graphics, meeting the diverse requirements of various customers.

● Details Dispaly

● Printing Sample

Post time: Jun-27-2025