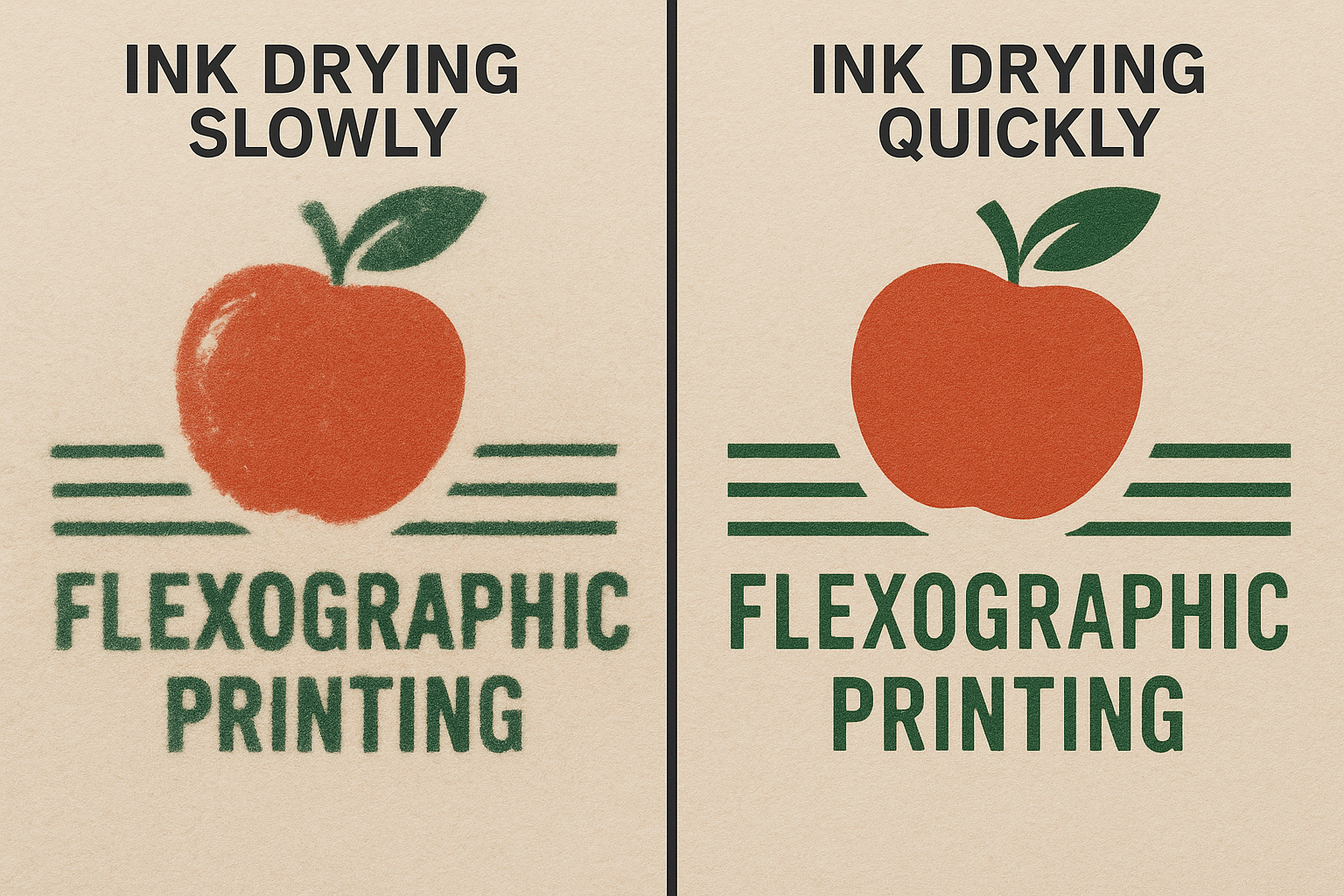

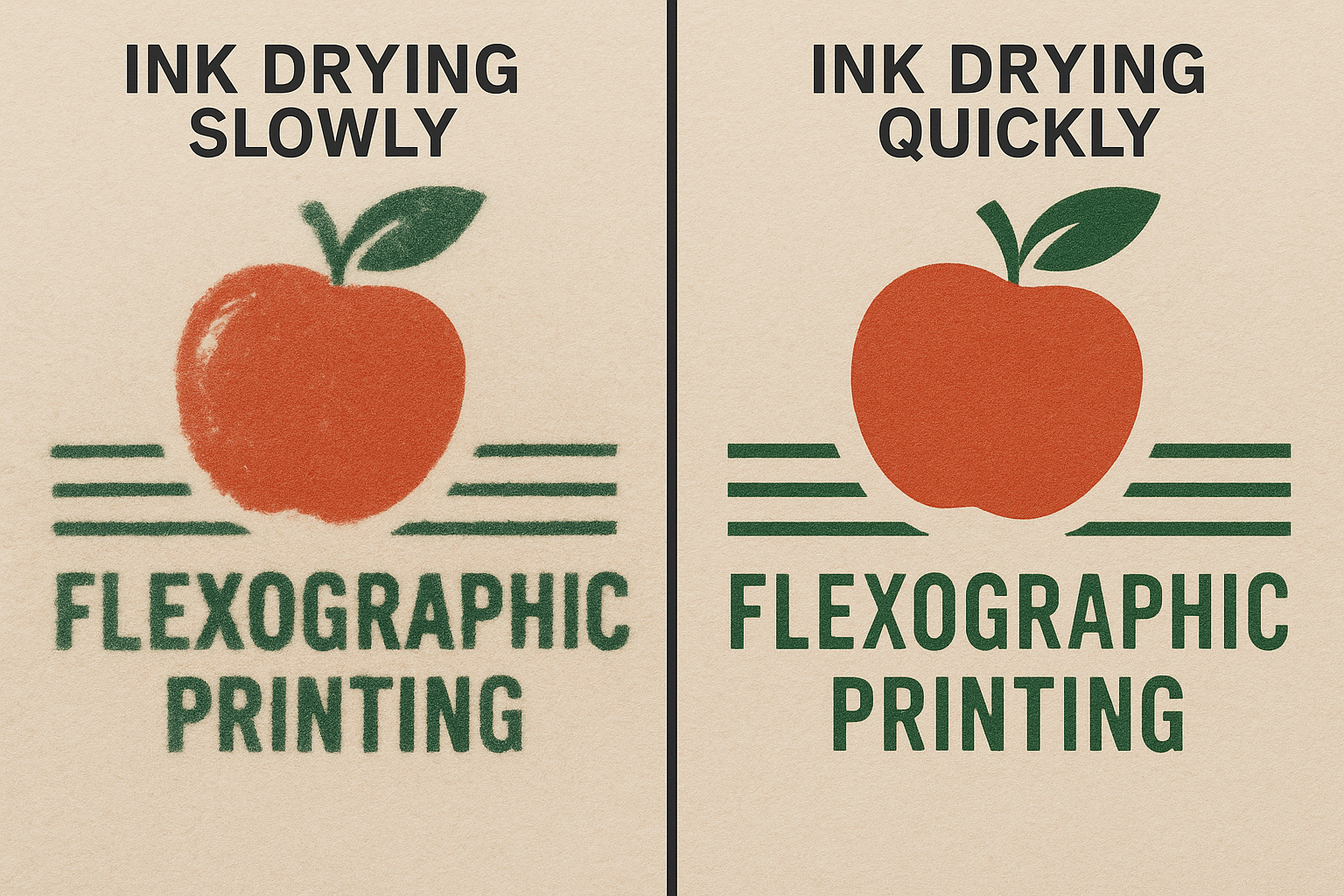

In the flexographic machines process, slow ink drying leading to smudging has been a persistent challenge for printing companies. This not only affects print quality and increases waste but also reduces production efficiency and may even delay delivery schedules. How can this issue be effectively resolved? We provide a comprehensive solution covering ink selection, process optimization, equipment upgrades, and environmental control to help you eliminate smudging and achieve stable, high-efficiency printing production.

In the flexographic machines process, slow ink drying leading to smudging has been a persistent challenge for printing companies. This not only affects print quality and increases waste but also reduces production efficiency and may even delay delivery schedules. How can this issue be effectively resolved? We provide a comprehensive solution covering ink selection, process optimization, equipment upgrades, and environmental control to help you eliminate smudging and achieve stable, high-efficiency printing production.

● Ink Selection & Formula Optimization – Solving Drying Issues at the Source

For flexo printing machines, ink selection and formulation are critical to addressing drying problems. We recommend fast-drying inks, such as solvent-based inks with high-volatility formulations or water-based inks with drying accelerators. For maximum drying speed, UV inks paired with ultraviolet curing systems are the best choice. Adjusting solvent ratios—such as increasing ethanol or ethyl acetate content—can enhance drying performance while maintaining ink stability. Additionally, selecting the right drying additives (e.g., cobalt/manganese driers for oxidative drying inks or specialized penetrants for absorbent substrates) ensures optimal results.

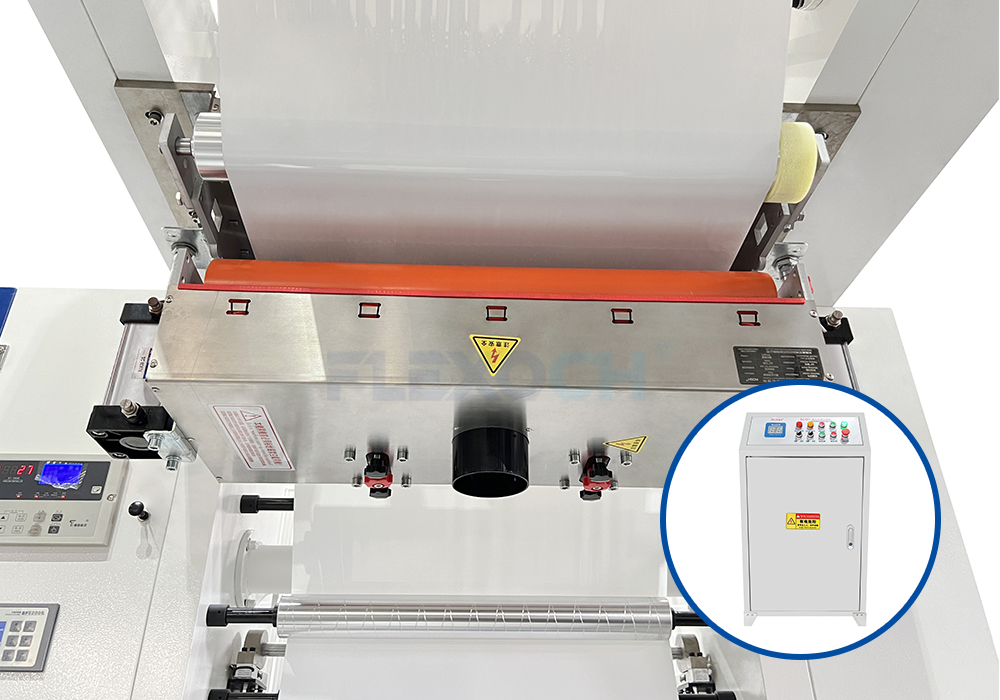

● Drying System Upgrades – Enhancing Efficiency

The performance of drying systems in a flexo printing machine directly impacts results. Regularly inspect dryers to ensure proper temperature settings (50–80°C for solvent inks, slightly lower for water-based) and unobstructed airflow. For demanding applications, upgrade to infrared drying for localized efficiency or UV curing for instant drying. Cold-air drying units are particularly useful for non-absorbent films to prevent ink rewetting.

● Printing Process Optimization – Adjusting Production Parameters

In flexographic printing machines, optimizing production parameters significantly improves drying efficiency. Controlling printing speed is crucial—excessive speed prevents proper drying before the next print station. Adjust speed based on ink properties and dryer capacity. Managing ink film thickness via proper anilox roller selection and ink volume prevents excessive buildup. For multi-color printing, increasing station spacing or adding interstation dryers extends drying time.

● Environment & Substrate Adaptation – Critical External Factors

Environmental conditions in flexo printer operations greatly affect drying. Maintain shop-floor temperature at 20–25°C and humidity at 50–60%. Use dehumidifiers in damp seasons. Substrate pretreatment (e.g., corona treatment for PE/PET films) enhances ink adhesion and reduces drying defects.

Corona Treatment

Humidity Control

Finally, a robust maintenance plan ensures long-term stability. Regularly clean dryer nozzles and heating elements, inspect anilox roller wear, and use dry-tension testers to monitor print quality—key steps in preventing drying-related issues.

Post time: May-29-2025