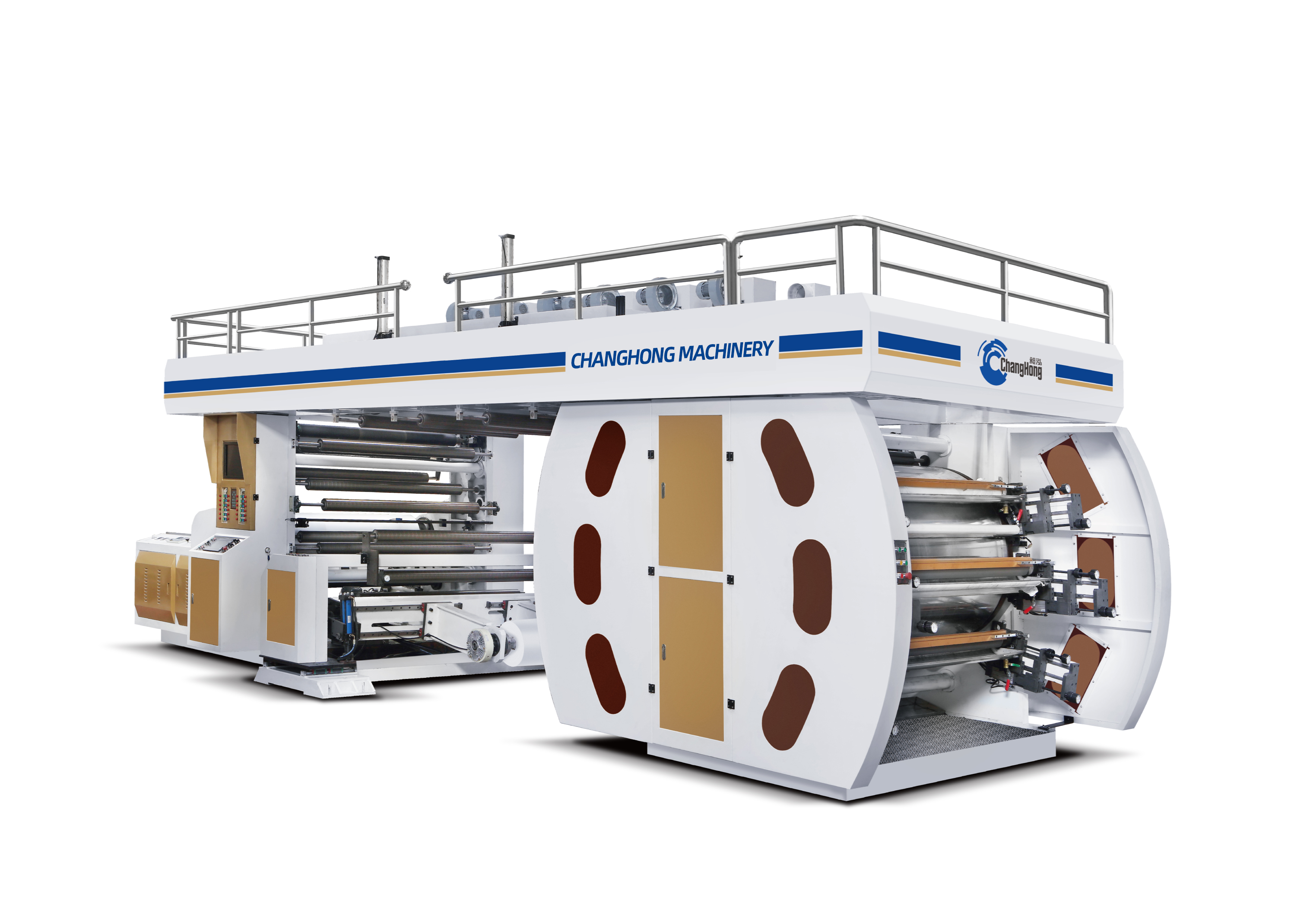

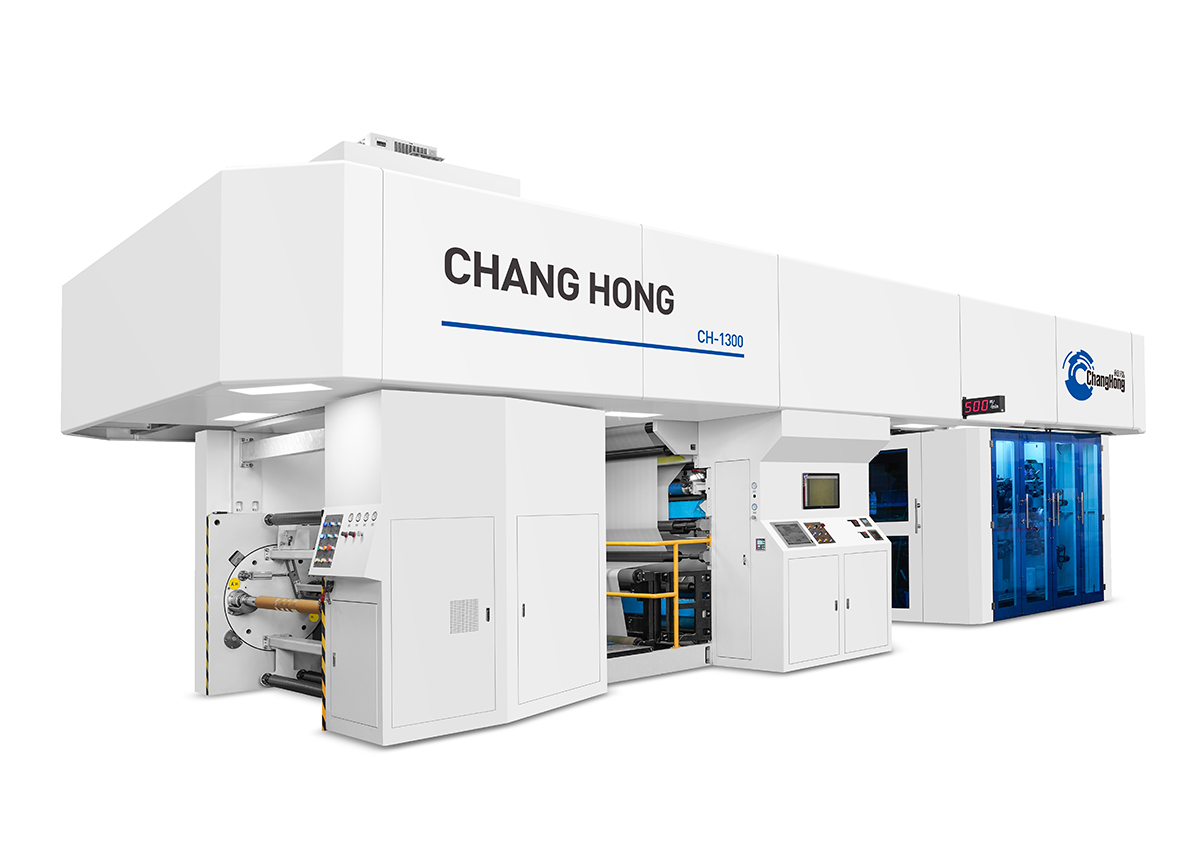

4 COLOR CI FLEXO PRINTING MACHINE FOR PLASTIC FILM/PAPER

4 COLOR CI FLEXO PRINTING MACHINE FOR PLASTIC FILM/PAPER

Technical Specifications

| Model | CHCI4-600J-S | CHCI4-800J-S | CHCI4-1000J-S | CHCI4-1200J-S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Machine Speed | 250m/min | |||

| Max.Printing Speed | 200m/min | |||

| Max. Unwind/Rewind Dia | Φ800mm/Φ1000mm/Φ1200mm | |||

| Drive Type | Central drum with Gear drive | |||

| Photopolymer Plate | To be specified | |||

| Ink | Water base ink or solvent ink | |||

| Printing Length (repeat) | 350mm-900mm | |||

| Range Of Substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Electrical Supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Video Introduction

Machine Features

● Method:Central impression for better color registration. With the central impression con figuration,theprinted material is supported by the cylinder,and greatly improving color registration, especially with extensible materials.

● Structure: Wherever possible, parts are communized for availability and wear-resisting design.

● Dryer: Hot wind dryer, automatic temperature controller, and separated heat source.

● Doctor blade: Chamber doctor blade type assembly for high-speed printing.

● Transmission: Hard gear surface, high precision Decelerate Motor, and encoder buttons are placed on both control chassis and body for operations convenience.

● Rewind: Micro Decelerate Motor, drive Magnetic Powder and Clutch, with PLC control tension stability.

● Gearing of Printing cylinder: repeat length is 5MM.

● Machine Frame: 100MM thick iron plate. No vibration at high speed and have a long service life.

Details Dispaly

Printing samples

Packaging and Delivery

Q: Are you a factory or trading company?

A: We are a factory, the real manufacturer not trader.

Q: Where is your factory and how can I visit it?

A: Our factory is located in fuding City, fujian Province, China about 40 minutes by plane from Shanghai ( 5 hours by train)

Q: What is your after-sale service?

A: We have been in flexo printing machine business for many years, we will send our professional engineer to install and test machine.

Beside, we can also provide online support, video technical support, matching parts delivery, etc. So our after-sales services is always reliable.

Q: How to get machines price?

A: Pls provide following information:

1)The color number of printing machine;

2)Material width and effective print width;

3)What material to print;

4)The photo of printing sample.

Q: What services do you have?

A: 1 Year Guarantee !

100% Good Quality !

24 Hours online Service!

The buyer paid tickets ( go and back to FuJian), and pay 150usd/day during the install and testing period!